Coal sample preparation device for true three-dimensional permeability determination

A preparation device and permeability technology, which is applied in the field of preparation devices for testing coal samples, can solve the problems of unused coal rock and other soft and fragile materials cutting, can not truly reproduce the stress state, and coal rock is difficult to apply, etc., to achieve reduction The risk of coal sample breakage, good cutting effect, and the effect of reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

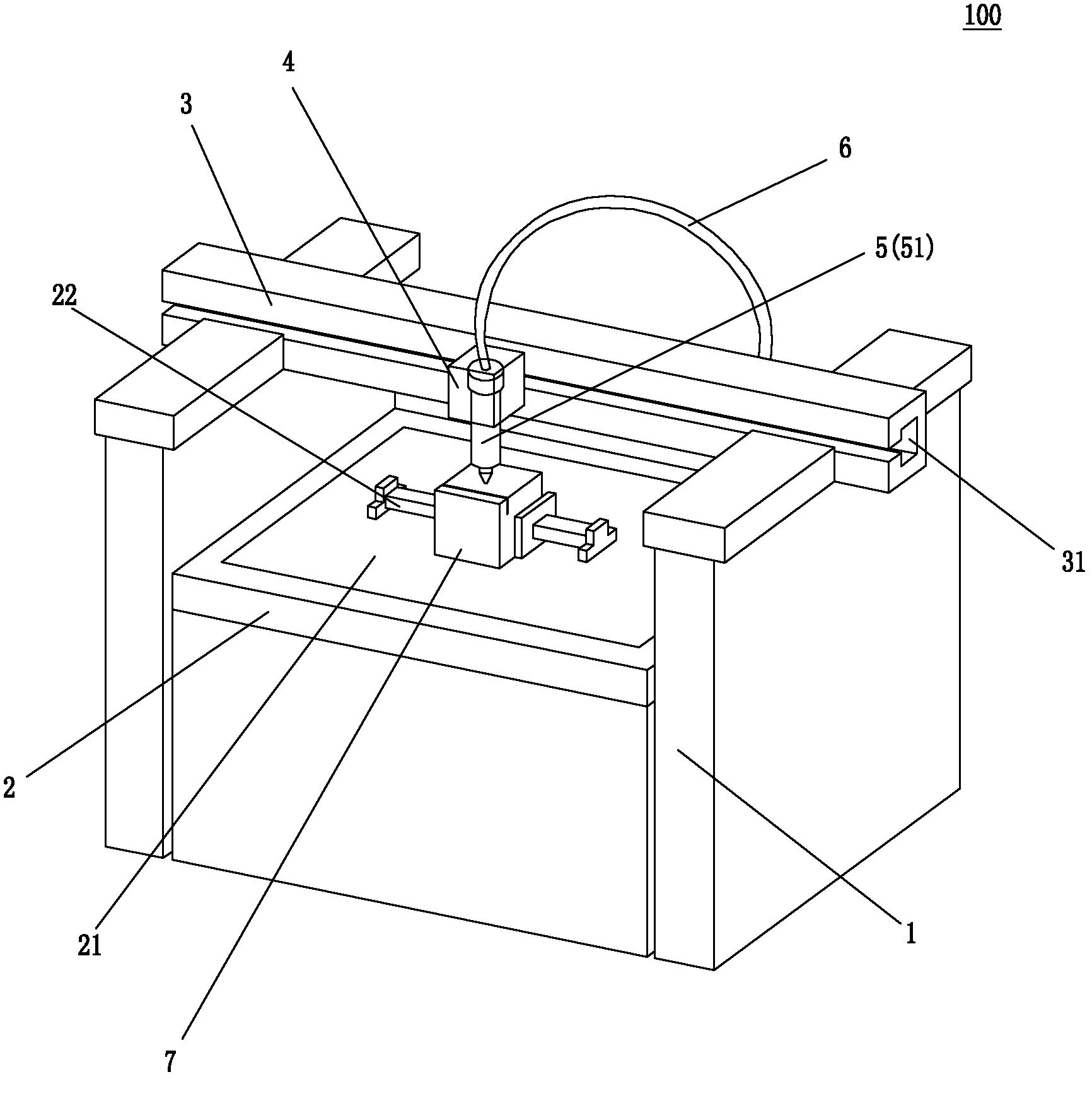

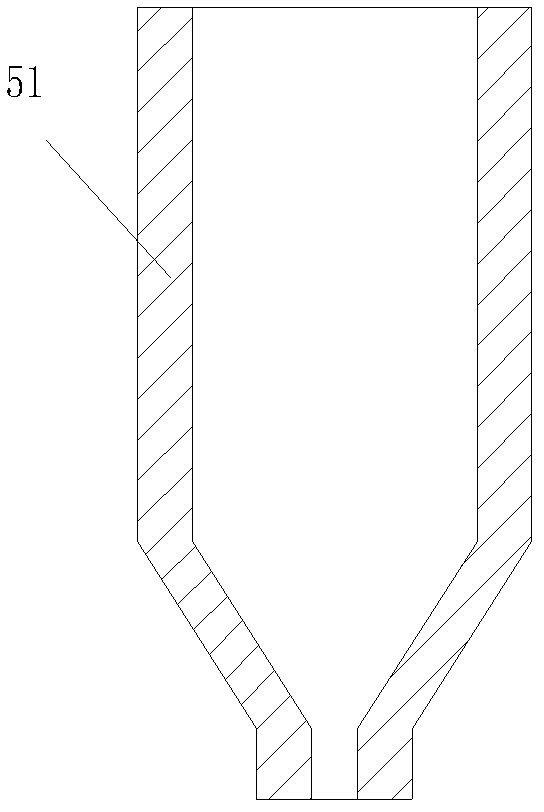

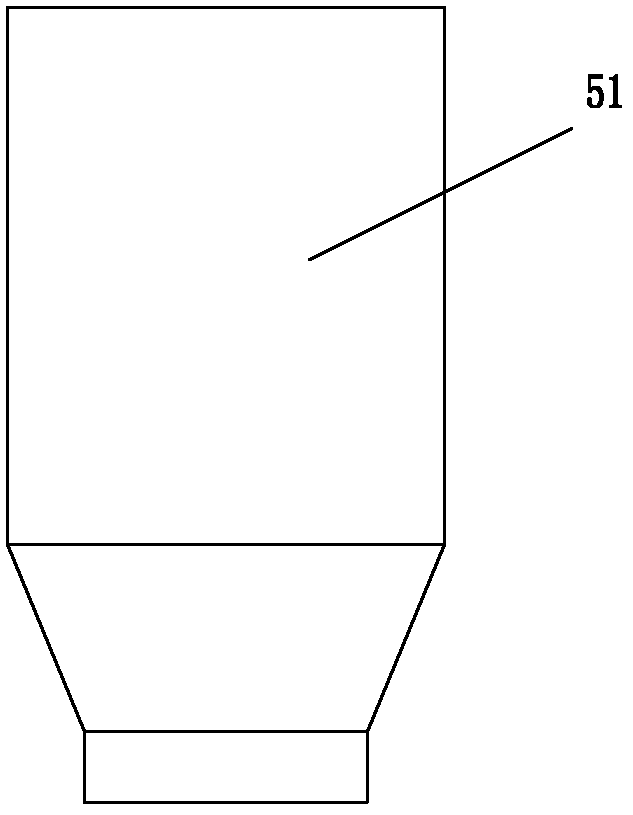

[0024] Such as figure 1 As shown, the present invention proposes a coal sample preparation device 100 for true three-dimensional permeability measurement. The preparation device 100 includes a fixed support 1, and a sample loading platform 2 is arranged on the fixed support 1. The sample loading platform 2 It is composed of a loading plane 21 and a sample holder 22 arranged on the loading plane 21; a sliding guide rail 3 is arranged above the sample loading platform 2, and the sliding guide rail 3 is arranged parallel to the loading plane 21; A slide block 4 is slidably arranged on the slide guide rail 3. In this embodiment, a T-shaped groove 31 is provided on the slide guide rail 3, and a guide block (not shown in the figure) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com