Method for preparing carbon hollow ball super-fine powder for negative pole of lithium ion battery by waste plastics at low temperature

A technology of lithium-ion batteries and carbon hollow spheres, applied in battery electrodes, carbon preparation/purification, circuits, etc., to achieve the effects of recycling waste, low reaction temperature, and environmental pollution control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: the low-temperature synthesis method of carbon hollow sphere ultrafine powder

[0044] Take 0.05mol HDPE (according to elemental carbon) plastic waste, 0.1mol metal sodium, 0.04mol metal magnesium powder (200 mesh) and 0.03mol sulfur powder, and put them into a stainless steel reactor (the volume of the reactor is 20ml), Seal it and place it in a resistance furnace, and react for 8 hours at 400°C (furnace temperature controlled at ±5°C) and 1 to 3 MPa; after stopping heating, cool the reaction kettle to room temperature naturally; % ethanol, 1mol / L hydrochloric acid, washed with water until the pH is neutral, centrifuged and vacuum-dried at 50°C for 6 hours to obtain a black powder product, that is, carbon hollow sphere superfine powder.

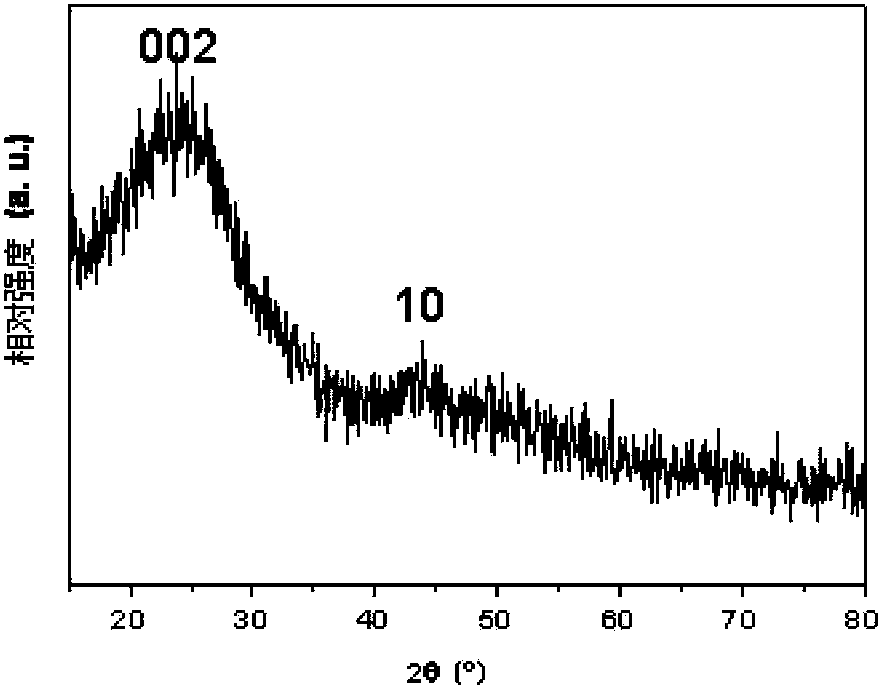

[0045]Cu Kα rays (wavelength The scanning step speed is 0.08° / sec) to analyze the product crop phase, and its main component is carbon. like figure 1 shown.

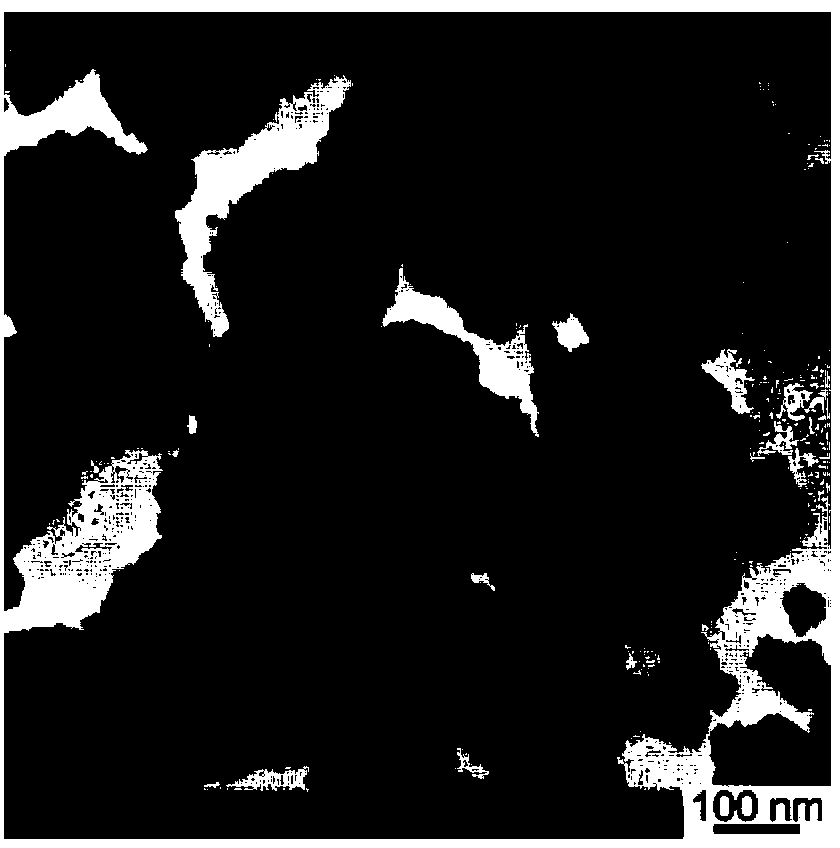

[0046] The morphology of the product was observed using ...

Embodiment 2

[0050] Embodiment 2: Low-temperature synthesis of carbon hollow sphere ultrafine powder

[0051] As described in Example 1, the difference is that the waste plastics in the raw materials are (calculated by simple carbon) 0.05mol LDPE plastic waste (shopping bags or garbage bags for supermarkets). It was synthesized at 400°C for 8 hours. The electrochemical performance characterization method is the same as in Example 1.

[0052] Figure 5 It is a low magnification TEM photo of the product obtained in this example after purification. The product contains a large amount of carbon hollow spheres with a diameter of about 150 nanometers and a wall thickness of about 20 nanometers. At the same time, the product contains a small amount of solid carbon spheres and carbon nanotubes, and the yield of carbon products is about 40%.

Embodiment 3

[0053] Embodiment 3: the low-temperature synthesis of carbon hollow sphere ultrafine powder

[0054] As described in Example 1, the difference is that the waste plastic in the raw material is 1g of PET plastic waste (mineral water bottle or beverage bottle). It was synthesized at 380°C for 10 hours. The electrochemical performance characterization method is the same as in Example 1.

[0055] Image 6 It is a low magnification TEM photo of the product obtained in this example. The product is mainly carbon hollow spheres with a diameter of about 170 nanometers and a wall thickness of about 25 nanometers. At the same time, the product contains some small particles and carbon nanotubes, and the yield of carbon products is about 42%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com