Technology for preparing titanium porcelain TiN/ZrTiSiN composite transition blocking layer for oral baked porcelain

A preparation process and barrier layer technology, applied in metal material coating process, coatings, dental preparations, etc., can solve the problems of coating peeling, implant failure, restricting the research of single coating, etc., to achieve low cost and improve the combination of Strength, effect of improving bond strength and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

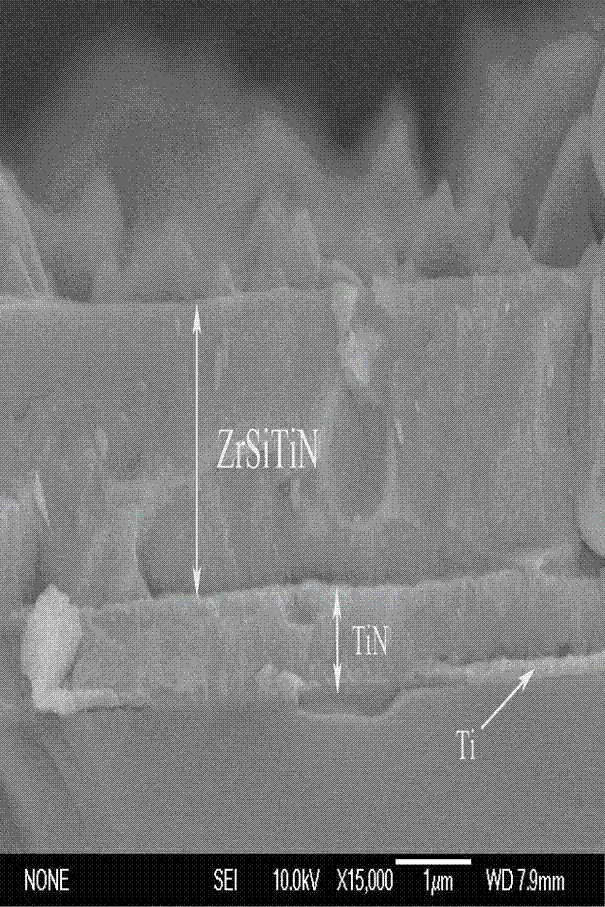

[0036]The preparation process of the TiN / ZrTiSiN composite transitional barrier layer for dental porcelain with high bonding strength and high thermal stability used in this example includes the following steps:

[0037] a. Clean the substrate material:

[0038] After cleaning the substrate material Ti matrix with hydrofluoric acid for 15 minutes, put it into acetone and absolute ethanol for 20 minutes of ultrasonic cleaning respectively, put it into a vacuum chamber after drying, and then evacuate to a degree of 5.0×10 -4 Pa;

[0039] b. Treatment of the substrate before deposition:

[0040] Under the vacuum condition of step a, clean with bias backsputtering for 10 minutes and pre-sputtering for 5 minutes to remove the substrate material Ti matrix and target impurities; the backsputtering power is 150 W; the pre-sputtering power is 150 W; The back-sputtering bias and pre-sputtering bias were -500 V and -150 V, respectively; the back-sputtering and pre-sputtering gases wer...

Embodiment 2

[0049] The operation steps of this example, the coating equipment used and other working conditions are the same as those of Example 1, and the deposition thickness of the double-layer transitional diffusion barrier layer is kept constant at 2.65 μm, and the deposition time of the TiN layer and the ZrTiSiN layer is adjusted to change the The thicknesses of the TiN layer and the ZrTiSiN layer in the double-layer transition barrier layer can also meet the high bonding strength and high thermal stability performance requirements of the titanium porcelain series.

[0050] In this example, the deposition time of the TiN layer was 70 minutes, and the deposition thickness was 0.9 μm; the deposition time of the ZrTiSiN layer was 80 minutes, and the thickness was 1.75 μm, so that the TiN / ZrTiSiN composite transition barrier layer sample was obtained. The obtained sample was analyzed by three-point bending test, and its bonding strength was 60 MPa. No titanium oxide was found at the por...

Embodiment 3

[0052] The operation steps of this example, the coating equipment used and other working conditions are the same as those of Example 1, and the deposition thickness of the double-layer transition barrier layer is kept constant at 2.65 μm, and the N in the TiN layer and the ZrTiSiN layer is adjusted. 2 The flow rate is used to change the deposition time of the TiN layer and ZrTiSiN layer on the double-layer transition barrier layer, and then change the deposition thickness of each layer, which can also meet the requirements of high bonding strength and high thermal stability of the titano-ceramic series.

[0053] N in this example 2 The flow rate is 60 Sccm, the deposition time of the TiN layer is 60 minutes, and the deposition thickness is 0.65 μm; the deposition time of the ZrTiSiN layer is 120 minutes, and the thickness is 2 μm, and the TiN / ZrTiSiN composite transition barrier layer sample is prepared. The obtained sample was analyzed by three-point bending test, and its bon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com