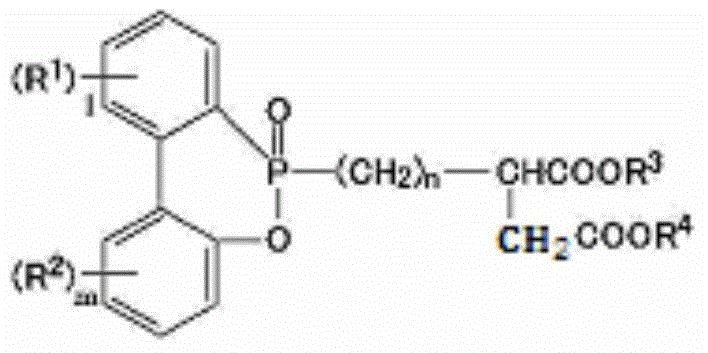

Composition for film, and adhesive film and cover lay film formed therefrom

A technology of composition and thin film, which is applied in the manufacture of printed circuits, electrical components, printed circuits, etc. It can solve the problems of resin hydrolysis or decrease in adhesion, and achieve the effects of good workability, low dielectric constant, and excellent adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0133] (Examples 1-8, Comparative Examples 1-4)

[0134] After dissolving each component with a solvent (butanone) to a predetermined solvent concentration, put it into a reaction kettle heated to 25°C at the mixing ratio (parts by mass) shown in the following table, and rotate it at a rotation speed of 300rpm for regular Mix under pressure for 1 hour.

[0135] After coating the obtained solution (varnish containing the film composition) on a substrate (PET film subjected to mold release treatment), the substrate was heated to remove the solvent, and then the film was removed from the substrate.

[0136] The abbreviations in the table are as follows.

[0137] (A) Ingredients

[0138] NC3000H: Biphenyl-type epoxy resin (manufactured by Nippon Kayaku Co., Ltd.)

[0139] Mn590

[0140] (B) Ingredients

[0141] UR3570: Polyurethane resin composed of phosphorus-containing polyols (manufactured by Toyobo Co., Ltd.)

[0142] Mn15000

[0143] (C) Ingredients

[0144] BMI-70...

Embodiment 9、 comparative example 5

[0174] The following evaluations were performed on a film produced in the same procedure as in Example 4 (Example 9) and a commercially available polyimide film (Kapton, manufactured by Toray DuPont Co., Ltd.) (Comparative Example 5). The film thicknesses were all 25 μm.

[0175] Peel strength: The film composition was sandwiched between polyimide films (Kapton 100H, manufactured by Toray DuPont Co., Ltd., thickness 25 μm) and hardened by vacuum molding (1 hr at 180° C., 1 MPa, vacuum degree < 10 kPa). The obtained sample was cut into a width of 10 mm, and the peel strength (180-degree peel, speed 50 mm / min) was measured with a universal testing machine (AG-IS manufactured by Shimadzu Corporation).

[0176] Folding resistance: The MIT test (R=1.MD) was implemented according to JIS P8115 about the film after heating and hardening at 150 degreeC*1h. The table below shows the number of bends at the point when the film breaks.

[0177] Insertion loss: A microstrip line was produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com