Pressure-sensitive adhesive composition for optical film and pressure-sensitive adhesive layer for optical film,

An optical film, adhesive layer technology, applied in the direction of film/sheet adhesive, adhesive type, pressure-sensitive film/sheet, etc., can solve problems such as preventing static electricity, uneven display, and bad conditions , to achieve the effect of suppressing heating, excellent antistatic function, and satisfying durability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

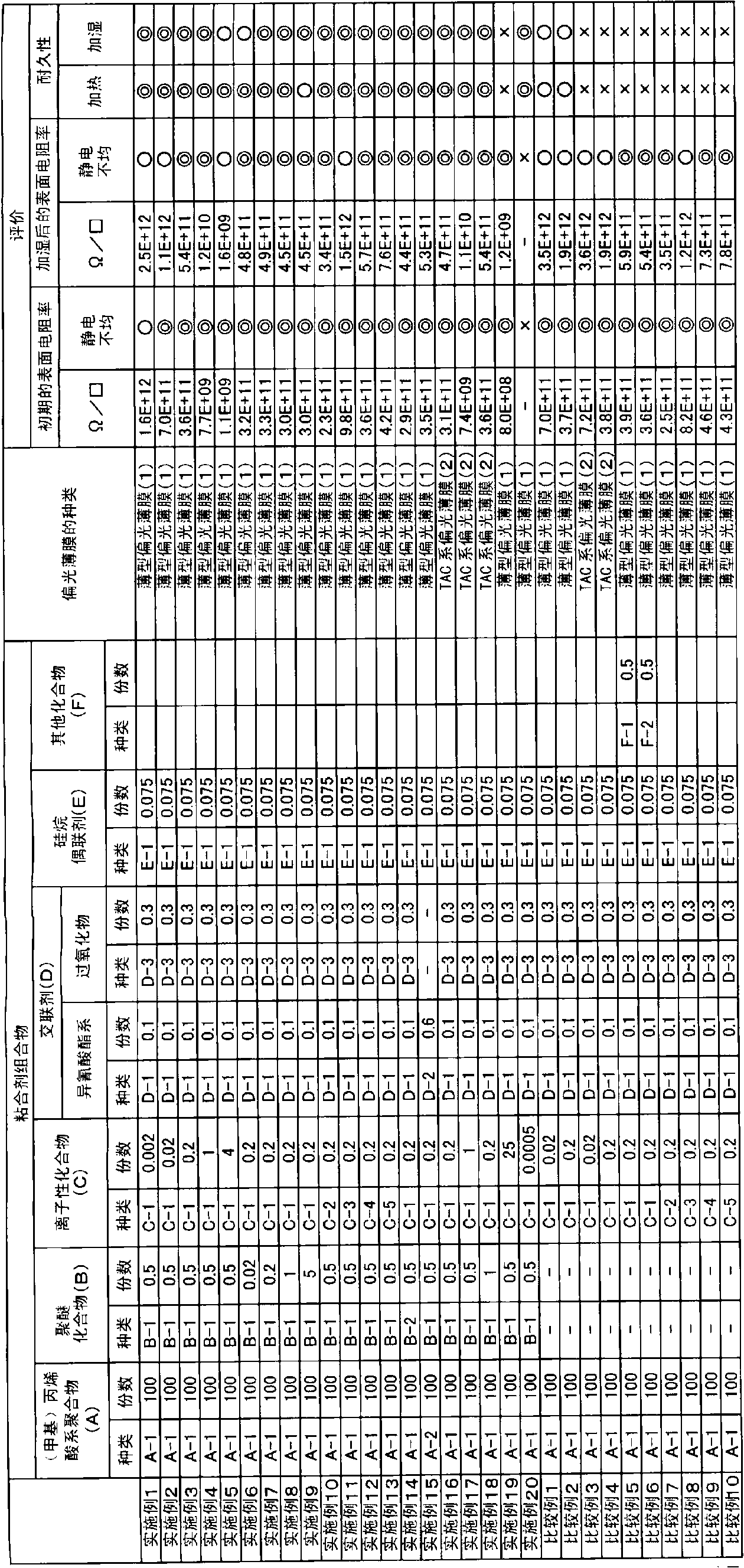

[0192] The following examples illustrate the present invention in detail, but the present invention is not limited by these examples. It should be noted that the parts and% in each example are based on weight. The room temperature storage conditions that are not specified below are all 23°C and 65%RH.

[0193] Measurement of the weight average molecular weight of (meth)acrylic polymer (A)

[0194] The weight average molecular weight of the (meth)acrylic polymer (A) is measured by GPC (gel permeation chromatography).

[0195] ·Analysis device: manufactured by TOSOH CORPORATION, HLC-8120GPC

[0196] ·Column: manufactured by TOSOH CORPORATION, G7000H XL +GMH XL +GMH XL

[0197] ·Column size: 7.8mmφ×30cm each, 90cm in total

[0198] ·Column temperature: 40℃

[0199] ·Flow rate: 0.8ml / min

[0200] ·Injection volume: 100μl

[0201] ·Eluent: Tetrahydrofuran

[0202] ·Detector: Differential Refractometer (RI)

[0203] ·Standard sample: polystyrene

[0204] Determination of the number average mo...

manufacture example 1

[0220] Preparation of acrylic polymer (A-1)

[0221] A four-necked flask equipped with a stirring blade, a thermometer, a nitrogen introduction tube, and a cooler was charged with a monomer mixture containing 82 parts of butyl acrylate, 15 parts of benzyl acrylate, and 3 parts of 4-hydroxybutyl acrylate. Furthermore, with respect to 100 parts of the aforementioned monomer mixture (solid content), 0.1 part of 2,2'-azobisisobutyronitrile as a polymerization initiator was added together with ethyl acetate, and nitrogen was introduced while slowly stirring to perform nitrogen After the replacement, the liquid temperature in the flask was maintained at around 60°C to perform the polymerization reaction for 7 hours. Then, ethyl acetate was added to the obtained reaction liquid to prepare a solution of acrylic monomer (A-1) with a weight average molecular weight of 1 million whose solid content concentration was adjusted to 30%.

manufacture example 2

[0223] Preparation of acrylic polymer (A-2)

[0224] In Production Example 1, as the monomer mixture, a monomer mixture containing 94.9 parts of butyl acrylate, 0.1 part of 2-hydroxyethyl acrylate, and 5 parts of acrylic acid was used. A solution of acrylic monomer (A-2) with a weight average molecular weight of 1 million.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com