Medical porous tantalum material for replacing dentale and preparation method thereof

A porous tantalum and dental bone technology is applied in the field of porous medical metal implant materials and their preparation, which can solve the problems affecting the processing and mechanical properties of porous tantalum materials such as ductility, compressive strength, and insufficient bending strength, so as to improve the biological phase. Compatibility and biosafety, good pore size uniformity and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

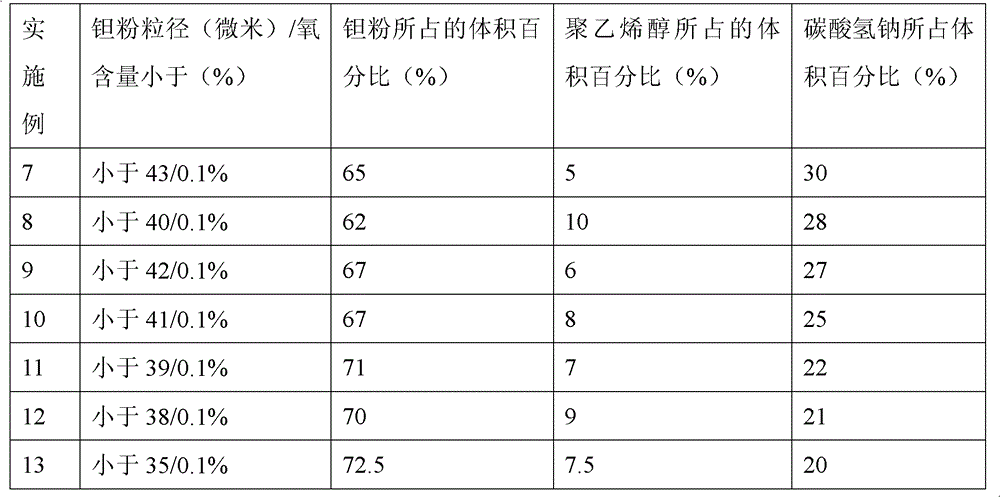

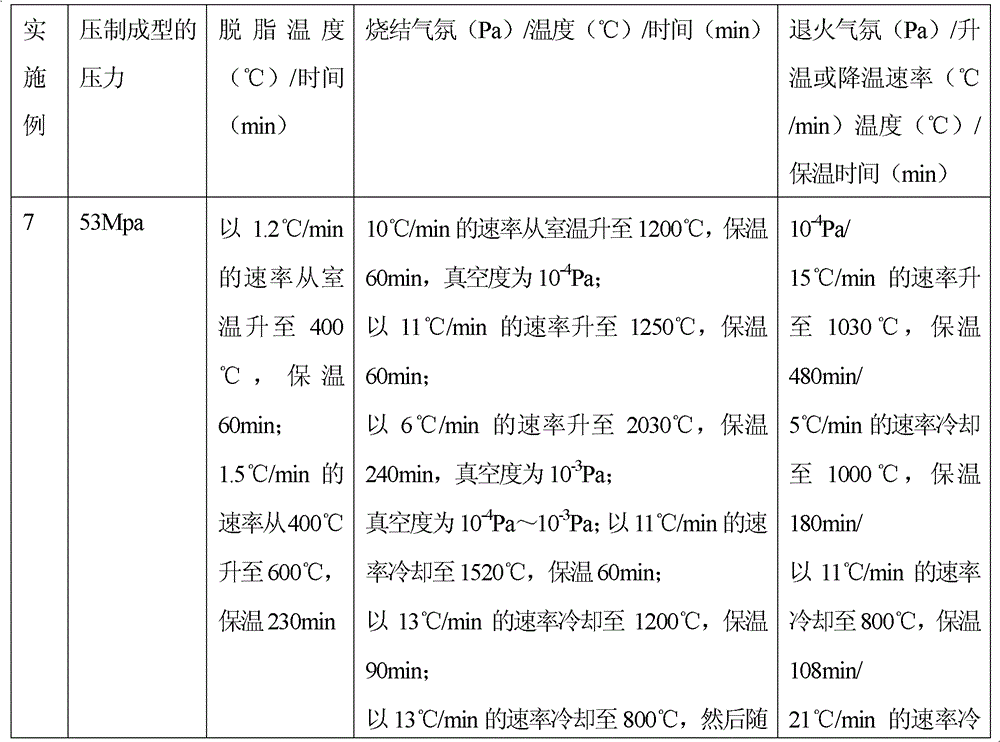

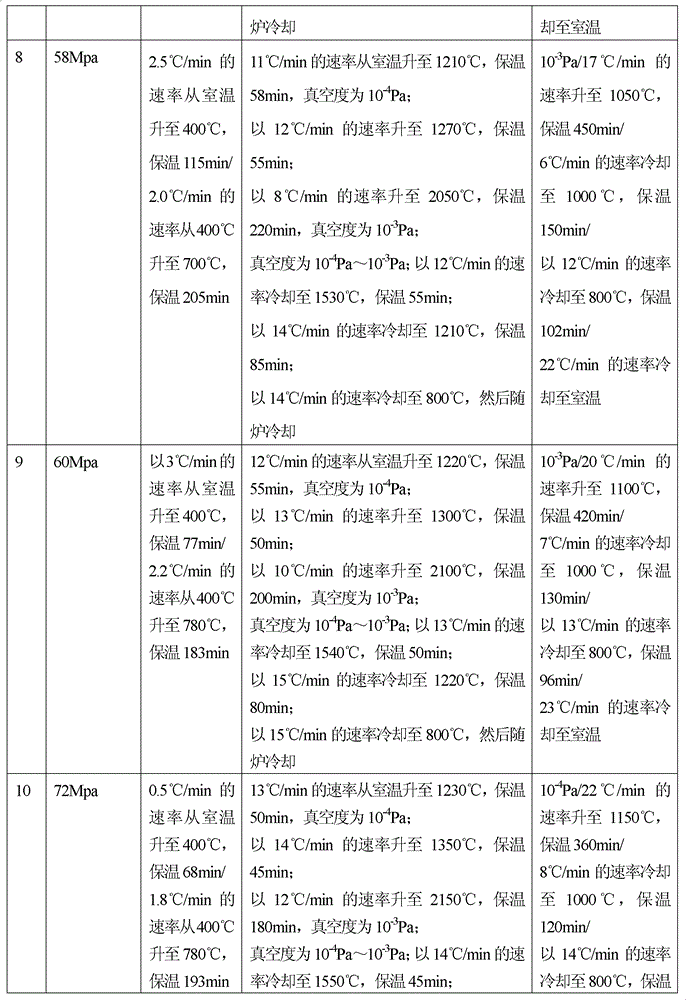

[0030] Example 1: Weigh polyvinyl alcohol, tantalum powder with an average particle diameter of less than 43 microns and an oxygen content of less than 0.1% and sodium bicarbonate and mix them uniformly to form a mixed powder, wherein polyvinyl alcohol accounts for 8%, sodium bicarbonate accounts for 27%, tantalum Powder accounted for 65%, all in volume percentage. Compression molding: the above mixed powder is pressed into polyurethane foam (pore diameter 0.48-0.89mm, density 0.015g / cm2) in an injection molding machine at 80Mpa 3 ~0.035g / cm 3 , hardness greater than 50°) in molding. Degreasing treatment: vacuum degree 10 -4 Pa, from room temperature to 400°C at a heating rate of 2.5°C / min, and hold for 100 minutes; then raise the temperature from 400°C to 700°C at a heating rate of 2°C / min, and hold for 220 minutes. Vacuum sintering: sintering in a vacuum furnace, the sintering temperature is 2000°C, the heat preservation is 2 hours, and the vacuum degree is 10 -4 Pa, the...

Embodiment 2

[0032] Embodiment 2: Weigh polyvinyl alcohol, tantalum powder with an average particle size less than 43 microns and an oxygen content of less than 0.1%, and sodium bicarbonate and mix them uniformly to form a mixed powder, wherein polyvinyl alcohol accounts for 6%, sodium bicarbonate accounts for 29%, tantalum Powder accounted for 65%, all in volume percentage. Compression molding: Add the above mixed powder into an injection molding machine and press it under 70Mpa to a hole diameter of 0.56-0.72mm and a density of 0.025g / cm 3 , molded in polyurethane foam with a hardness of 50°-80°. Degreasing treatment: vacuum degree 10 -4 Pa, raise the temperature from room temperature to 400°C at a heating rate of 1°C / min, and hold for 60 minutes; then raise the temperature from 400°C to 800°C at a heating rate of 2.5°C / min, and hold for 180 minutes. Vacuum sintering: sintering in a vacuum furnace, the sintering temperature is 2100°C, the heat preservation is 4 hours, and the vacuum de...

Embodiment 3

[0034] Embodiment 3: Weigh polyvinyl alcohol, tantalum powder with an average particle diameter of less than 43 microns and an oxygen content of less than 0.1%, and sodium bicarbonate and mix them uniformly to form a mixed powder, wherein polyvinyl alcohol accounts for 10%, sodium bicarbonate accounts for 23%, tantalum Powder accounted for 67%, all by volume percentage. Compression molding: Add the above mixed powder into an injection molding machine and press it under 52Mpa to a hole diameter of 0.56-0.72mm and a density of 0.025g / cm 3 , molded in polyurethane foam with a hardness of 50°-80°. Degreasing treatment: vacuum degree 10 -4 Pa, raise the temperature from room temperature to 400°C at a heating rate of 3°C / min, and hold for 120 minutes; then raise the temperature from 400°C to 750°C at a heating rate of 1.5°C / min, and hold for 240 minutes. Vacuum sintering: sintering in a vacuum furnace, the sintering temperature is 2200°C, the heat preservation is 2.5 hours, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com