Treatment solution for preparing molybdenum-cerium composite conversion membrane on surface of magnesium alloy, and treatment method thereof

A treatment method and technology for treating liquid, applied in the direction of metal material coating process, etc., can solve the problems affecting the corrosion resistance of the film layer, the solution stability is not good enough, the film forming speed is fast, etc., and achieve high protection performance and stable cation concentration. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

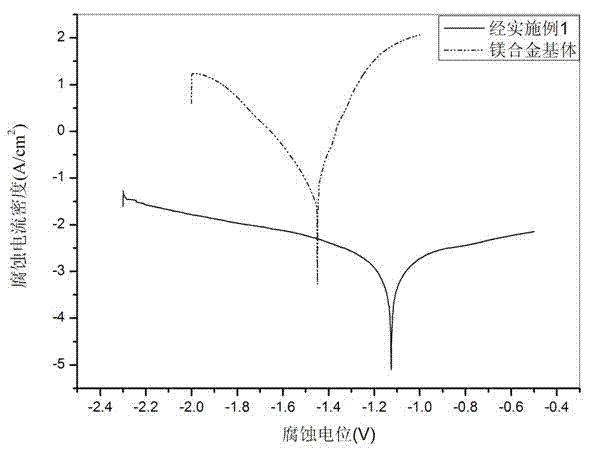

Embodiment 1

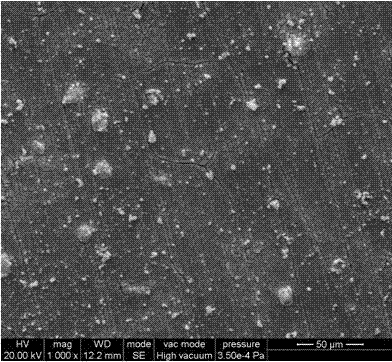

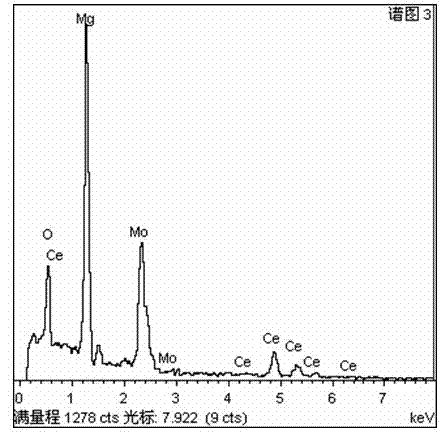

[0060] The process for preparing a composite chemical conversion coating containing colored molybdenum and cerium on the surface of a magnesium alloy includes the following steps:

[0061] (1) Sample preparation: Wire cutting from large-size AZ91 cast magnesium alloy, cut out 30×20mm samples, punch holes in the corners of each sample, and polish the magnesium alloy surface to 1500# with SiC water sandpaper, Rinse it with distilled water and dry it, and hang it with a thin wire at the hole;

[0062] (2) Pretreatment activation: Soak the sample in an alkaline solution at 30°C for 3 minutes, then rinse it with distilled water and dry it with a hair dryer for later use. The concentration of each component in the alkaline solution is Sodium 10g / L, trisodium phosphate 35g / L, sodium silicate 13g / L, sodium carbonate 15g / L.

[0063] (3) Treatment solution preparation: prepare 200mL conversion solution, in which the various components and concentrations in the treatment solution are as...

Embodiment 2

[0070] The basic process for preparing the conversion film in this example is similar to that in Example 1. The sample preparation and pretreatment activation are exactly the same as in Example 1, the difference lies in the concentration of the treatment solution and the preparation process of the conversion film.

[0071] The concentration of the treatment solution used in this embodiment and its preparation process are as follows: Prepare 200mL conversion solution, wherein the various components and concentrations in the treatment solution are as follows: ammonium molybdate 4.5g / L, cerium ammonium nitrate 9.0g / L, citric acid 2.0 g / L, EDTA-2Na 0.1g / L. Dissolve 0.9 g of ammonium molybdate, 1.8 g of cerium ammonium nitrate, 0.4 g of citric acid, and 0.02 g of EDTA-2Na in water, adjust the pH value to 2.5, and add water until the volume of the treatment solution is 200 mL. The solution preparation process and after preparation need to be stirred with a magnetic stirrer for 3 mi...

Embodiment 3

[0074] The basic process for preparing the conversion film in this example is similar to that in Example 1. The sample preparation and pretreatment activation are exactly the same as in Example 1, except that the concentration of the treatment solution and the preparation process of the conversion film are different.

[0075] The concentration of the treatment solution used in this embodiment and its preparation process are as follows: Prepare 200mL conversion solution, wherein the various components and concentrations in the treatment solution are as follows: sodium molybdate 3.5g / L, cerium nitrate 7g / L, citric acid 1.5 g / L L, EDTA-2Na 0.1g / L. Dissolve 0.7g of sodium molybdate, 1.4g of cerium nitrate, 0.3g of citric acid, and 0.02g of EDTA-2Na in water, adjust the pH value to 2.5, and add water until the volume of the treatment solution is 200mL. The solution preparation process and after preparation need to be stirred with a magnetic stirrer for 3 minutes at a speed of 100 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Self-corrosion current density | aaaaa | aaaaa |

| Self-corrosion current density | aaaaa | aaaaa |

| Self-corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com