Electron beam filler wire welding method of TC4 titanium alloy and QCr0.8 copper alloy

A qcr0.8, titanium alloy technology, applied in electron beam welding equipment, welding medium, welding equipment and other directions, can solve the problems of inability to meet the requirements of weld mechanical properties, metal metallurgy incompatibility and physical properties mismatch, etc. Achieve the effect of eliminating welding defects, improving stability and efficiency, and improving weld formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

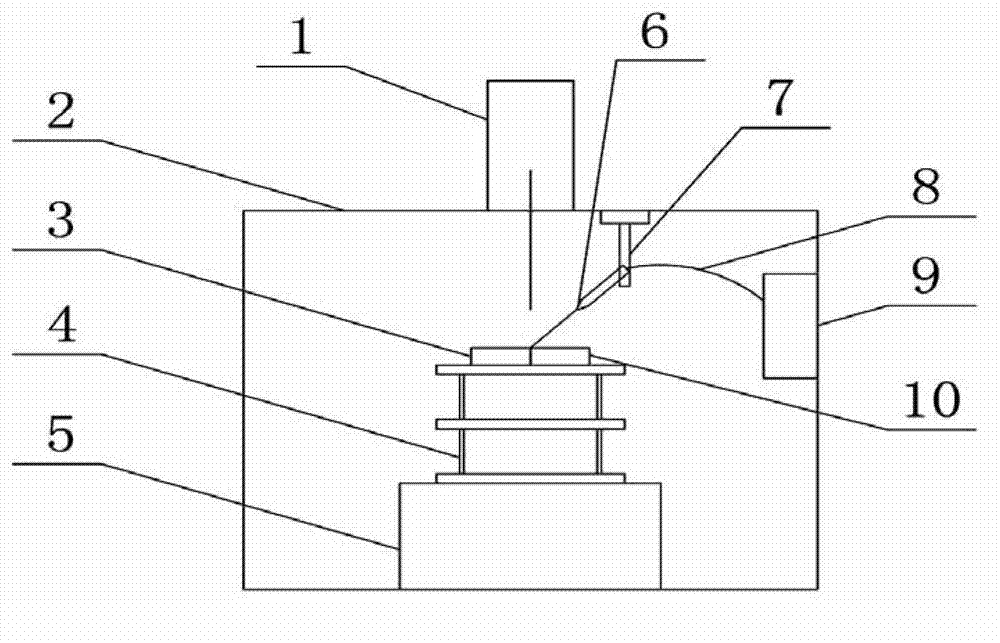

[0015] Specific embodiment one: in the present embodiment, the electron beam welding method of TC4 titanium alloy and QCr0.8 copper alloy is carried out according to the following steps:

[0016] 1. Use 600# or 800# metallographic sandpaper to grind the surface of TC4 titanium alloy and QCr0.8 copper alloy to expose the rust-free surface to be welded, then wipe the surface to be welded with acetone, and then clean the TC4 titanium alloy The surface to be welded with the QCr0.8 copper alloy is fixed on the lifting platform in a docking manner. The gap between the two surfaces to be welded is 0.1mm~0.3mm. The lower beam point of the electron beam emitted by the electron gun is aligned by moving the CNC worktable. At the center of the welding head, the mass percentage of TC4 titanium alloy is composed of Al: 6.2%, V: 3.5%, impurities ≤ 0.2%, the balance is Ti, and the mass percentage of QCr0.8 copper alloy is composed of Cr: 0.4%~0.7%, Impurity ≤ 0.8%, the balance is Cu;

[0017...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment differs from Embodiment 1 in that the gap between the two surfaces to be welded in step 1 is 0.2 mm. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment one is: in step one, the mass percentage of TC4 titanium alloy is composed of Al: 6.2%, V: 3.5%, impurity 0.05% ~ 0.15%, and the balance is Ti, QCr0 .8 The mass percentage of copper alloy is composed of Cr: 0.5%~0.6%, impurities: 0.1%~0.5%, and the balance is Cu. Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com