Preparation method of wood-organic-inorganic hybridized nano composite material based on doped nano POSS (Polyhedral Oligomeric Silsesquioxane)

A nano-composite material and wood technology, which is applied in the direction of impregnated wood, wood impregnation, wood processing equipment, etc., can solve the problems of low impact toughness, poor mechanical properties of wood-inorganic (nano) composite materials, poor thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

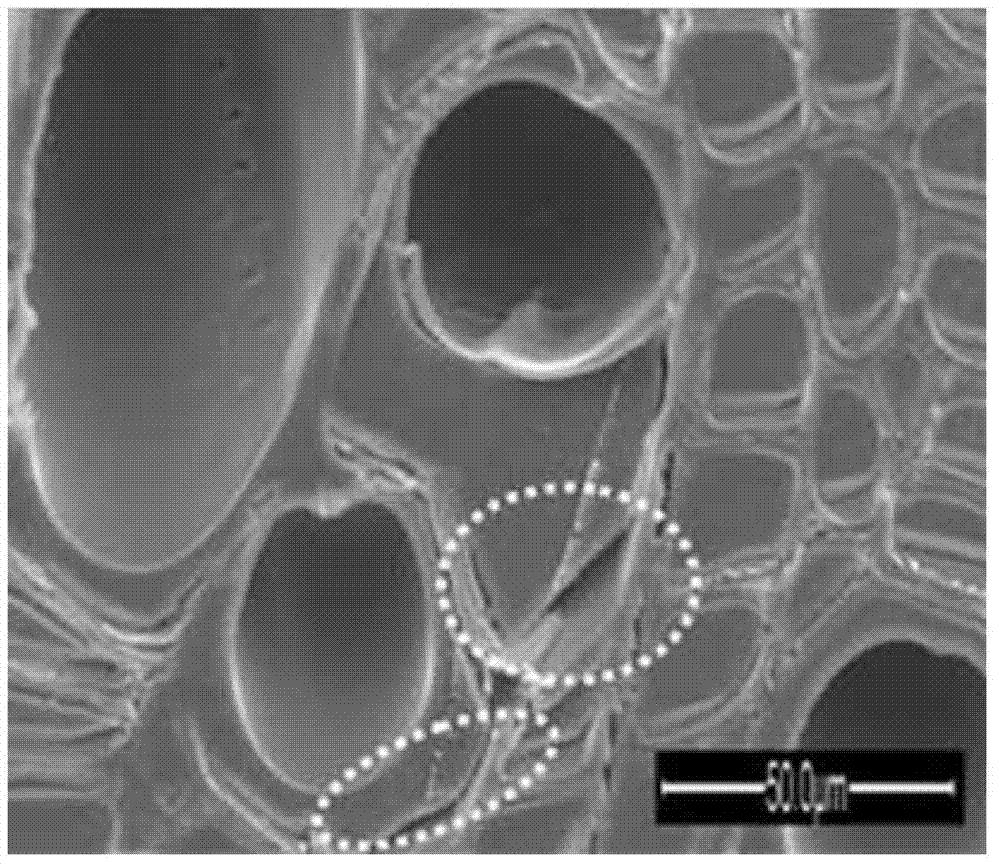

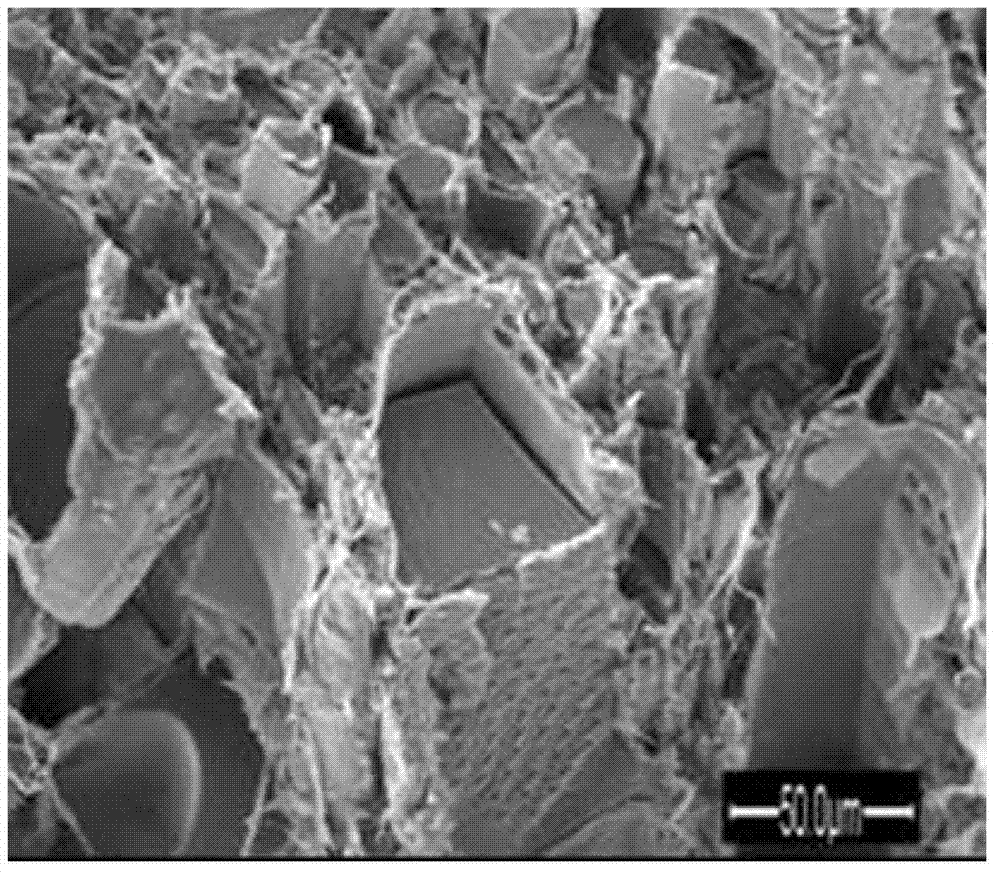

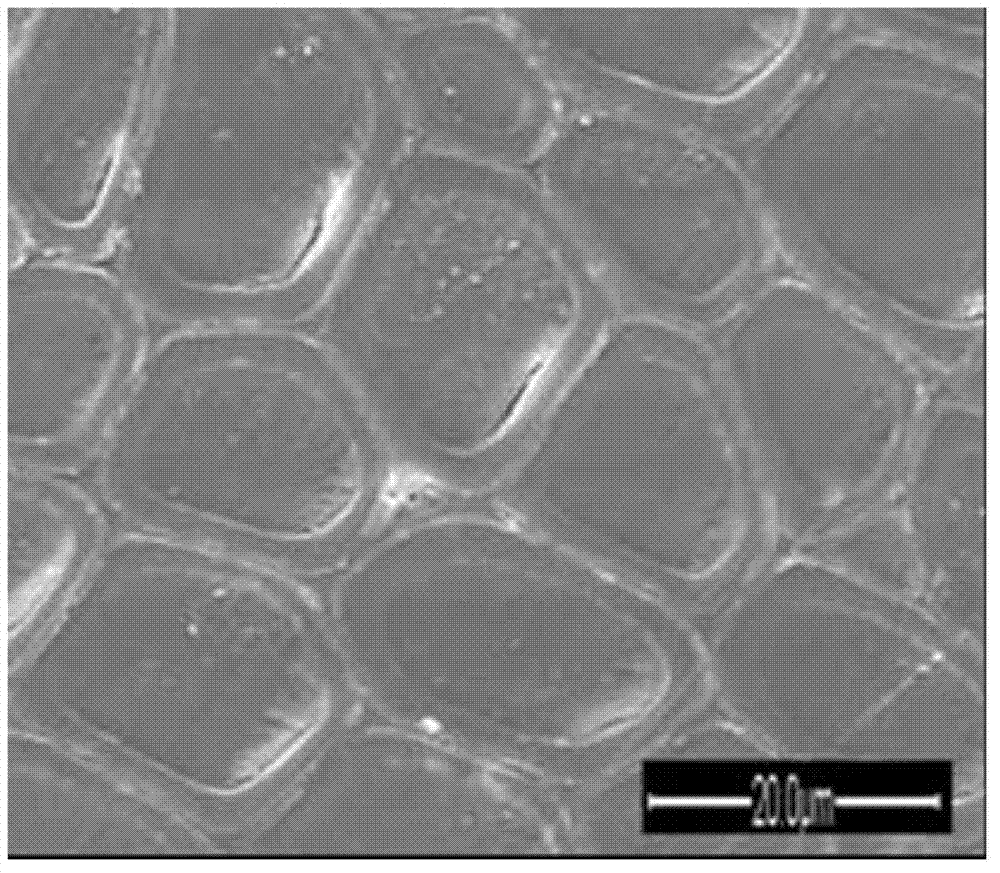

Image

Examples

specific Embodiment approach 1

[0033] Specific embodiment one: the preparation method of the wood-organic-inorganic hybrid nanocomposite material based on nano POSS doping in this embodiment is carried out according to the following steps:

[0034] 1. Weigh 1 mass part of the functional monomer and the toughening agent and mix them uniformly, the mass of the toughening agent is 1% to 150% of the mass of the functional monomer to obtain a monomer solution;

[0035]2. Weigh 0.1% to 10% POSS (with organic amine functional groups) of the monomer solution mass obtained in step 1, then dry the POSS for 24 hours at 105°C and 0.01MPa under vacuum drying conditions, and then dehydrate the POSS with tetrahydrofuran The dried POSS is dissolved to obtain a POSS tetrahydrofuran solution with a POSS mass concentration of 1% to 20%, and the POSS tetrahydrofuran solution is added to the monomer solution in step 1, and stirred evenly to obtain a transparent monomer solution in which nano-POSS is dissolved;

[0036] Three, t...

specific Embodiment approach 2

[0049] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass of the toughening agent in step 1 is 50% of the mass of the functional monomer. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0050] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in Step 2, 5% POSS by weight of the monomer solution obtained in Step 1 is weighed. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com