AN/Crl-xAlxN/Cr30 (Al, Y) 70N hard gradient coating and preparation method thereof

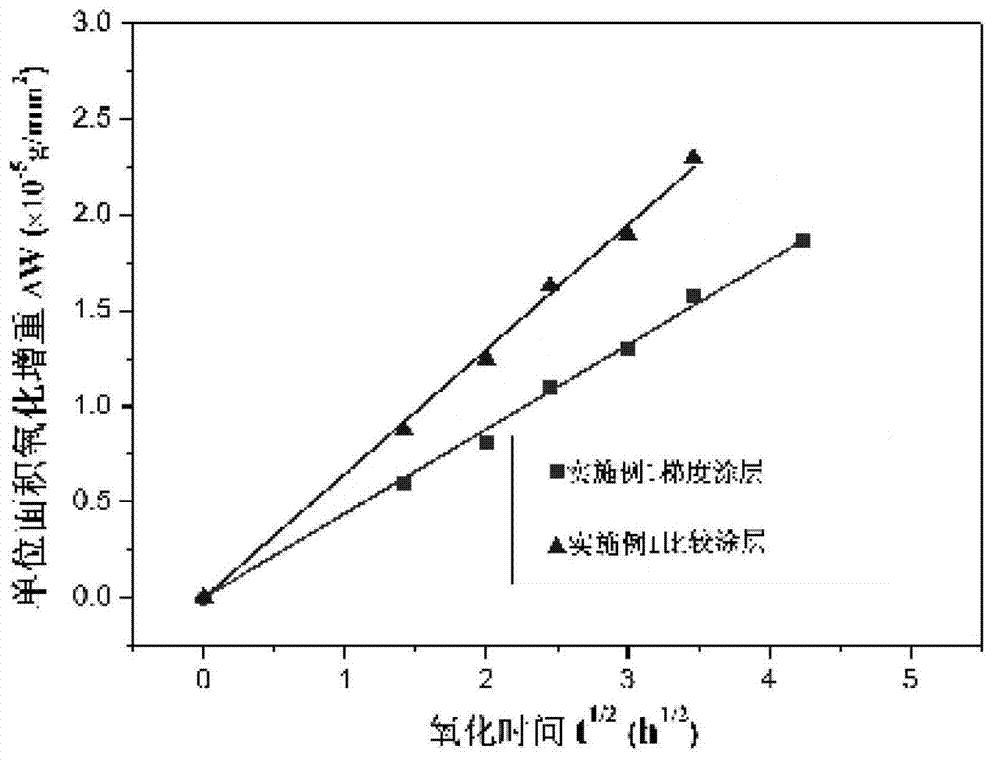

A gradient coating and coating technology, applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of affecting the bonding force of coating film base, low ionization rate of sputtering particles, and other problems. , to improve thermal performance and high temperature oxidation resistance, to avoid the effect of sub-interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

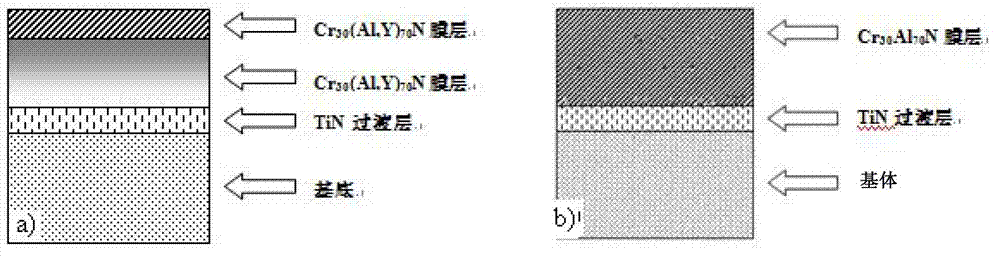

[0036] Example 1 High-speed steel (SKH51) milling cutter and surface coating treatment of test piece

[0037] The material grade of the milling cutter is SKH51. During the surface treatment, a 10x10x20 (mm) rectangular sample with the same heat treatment system (the Rockwell hardness is HRC65 after quenching + tempering treatment) is placed in the furnace, and one side of the sample is ground and polished. , in order to coat TiN / Cr 1-x Al x N / Cr 30 (Al,Y) 70 The relevant properties were tested after N gradient coating.

[0038] (1) Surface pretreatment of workpieces and samples: Boil the workpieces and samples in alkaline metal cleaning solution for 120 minutes to degrease the surface (the oil stain on the surface of the milling cutter is serious); place the workpieces and samples in an alkaline solution at room temperature Ultrasonic cleaning machine (frequency 40kHz, intensity 100W / liter) for metal cleaning liquid for 15 minutes; put the cleaned workpieces and samples in...

Embodiment 2

[0047] The surface treatment of embodiment 2 cemented carbide rail machining blade

[0048] A CrN / Cr 1-x Al x N / Cr 30 (Al,Y) 70 The preparation method of N gradient coating comprises the following steps and process conditions:

[0049] (1) Pretreatment of the surface of the hard alloy rail processing knife: put the blade in an alkaline metal cleaning solution and boil for 40 minutes to degrease the surface; at room temperature, place the blade in an ultrasonic cleaning machine (frequency 20kHz , the intensity is 10W / liter) in ultrasonic treatment for 10 minutes; put the cleaned blade into pure ethanol solution for dehydration, and then place it in an oven at 120°C for 60 minutes.

[0050] (2) Preheating of carbide rail processing blades: put the pretreated blades into a vacuum coating furnace, and vacuumize to 5x10 -3 After Pa, pass Ar gas to maintain a vacuum of 2.3x10 -1 Pa, start the HCD electron gun and the auxiliary auxiliary resistance heating device in the furnace...

Embodiment 3

[0056] Example 3 Surface Treatment of Cold Work Die Steel SKD1 Alloy Substrate

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com