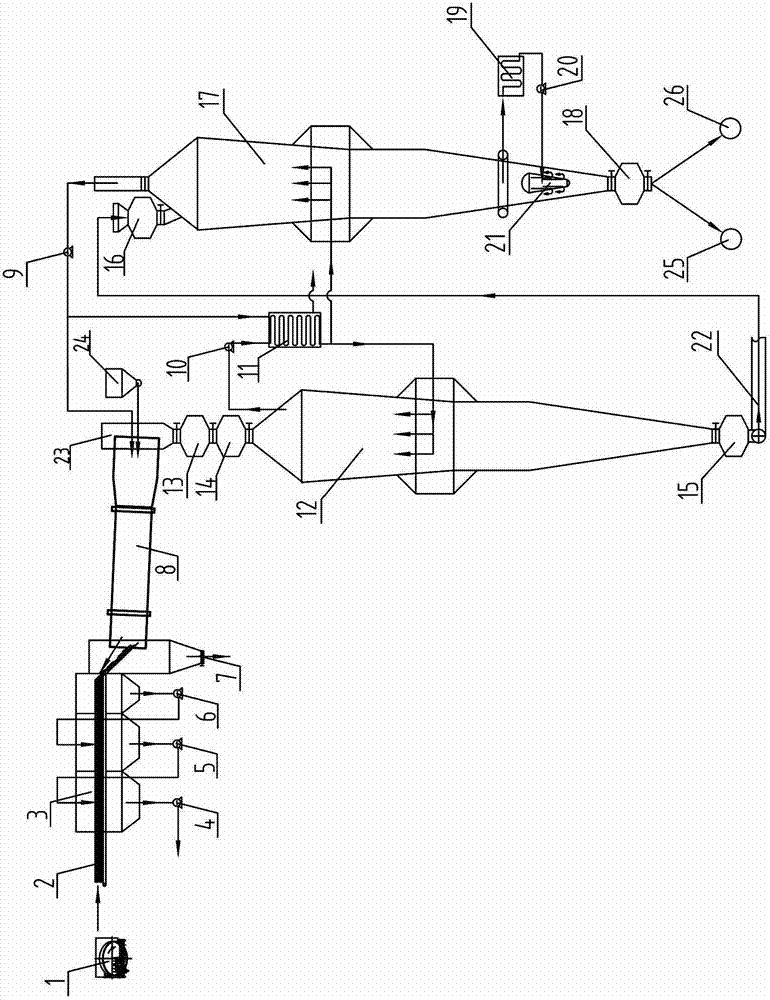

Shortened production equipment and method of coal-based direct reduced iron

A direct, equipment technology, applied in the metallurgical field, which can solve the problems of high cost, inability to meet the demand for reduced iron, and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Laboratory restoration:

[0050] Put 200g of the above-mentioned oxidized pellets into the crucible, place the crucible in a muffle furnace and raise the temperature to 1150°C, which is basically the same as the temperature of the oxidized pellets discharged from the rotary kiln;

[0051] Make reductant, used bituminous coal index as shown in table 3, used lime as shown in table 4;

[0052] Prepare reducing agent, by weight percentage,

[0053] Bituminous coal: lime powder = 88:12, that is, bituminous coal accounts for 88% of the total weight of the reducing agent, and lime accounts for 12% of the total weight

[0054] Table 3 Bituminous coal index (composition by weight percentage)

[0055] Ash

Volatile matter

Sulfur content

13.00

28.00

57.00

0.45

1.55

0~6mm

[0056] Table 4 Lime index (composition by weight percentage)

[0057] CaO

Sulfur content...

Embodiment 2

[0064] Small Industrial Trials:

[0065] Get 5000g of the above-mentioned oxidized pellets, the reducing agent proportion and index are exactly the same as those in Example 1.

[0066] Self-made a volume of 0.1m 3 A sealed thermal insulation cone container is inlaid with thermal insulation bricks, and electric furnace wires are connected in series in the thermal insulation bricks. Heat the insulation cone container to 1000°C first, and set it aside.

[0067] Heat the oxidized pellets to 1120°C, quickly mix them evenly with the cold reducing agent, immediately put them into a conical container at 1050°C, cover the lid, heat to 1020°C with electricity, and keep warm for 7 hours; then cool down to 900°C, keep warm for 4 hours ; then lower the temperature to 850°C and keep it warm for 4 hours; stop power transmission and cool down naturally. When the temperature drops to 300°C to 400°C, pour out the material and bury it in cold coal for 40 minutes. Use a magnet to suck out the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com