A kind of n-fe/fec 3 @acMicrobial fuel cell air cathode electrocatalytic material and preparation method thereof

An electrocatalytic material and fuel cell technology, applied in the direction of biochemical fuel cells, battery electrodes, electrical components, etc., can solve the problems of easy poisoning, scarcity, and high price of various compounds, so as to improve the distribution of active sites and mature the preparation process , the effect of good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]N-Fe / FEC3The preparation method of @AC microbial fuel cell air cathode composite electrocatalytic material, including the following steps:

[0034](1) 2G activated Carbon, AC was added to 100 ml of deionized water, and the ultrasonic dispersion was dispersed for 30 min, and uniformly dispersed activated carbon solution, spare;

[0035](2) Potassium 0.014mol ferride (K4Fe (CN)6· 3h2O) and 1G Polyvinylpyrrolidone (PVP) ultrasonic dispersion in the solution obtained by step (1), after the force is stirred for 3 h;

[0036](3) Slowly drop 100ml 0.187mol·L to the solution obtained from step (2)-1Iron chloride (FECL3· 6h2O) The solution was continued for 4 h, followed by static treatment at room temperature 24h;

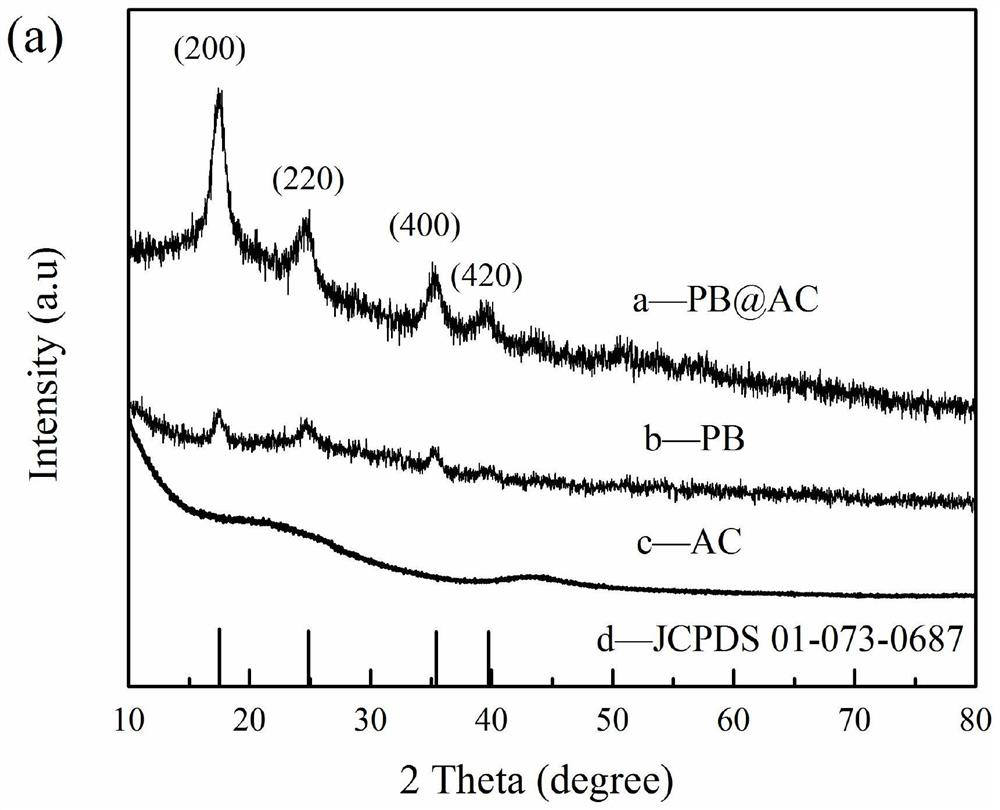

[0037](4) Filtering the solution, ethanol and deionized water repeatedly after several times, after several times, drying overnight product is produced for the PB @ AC;

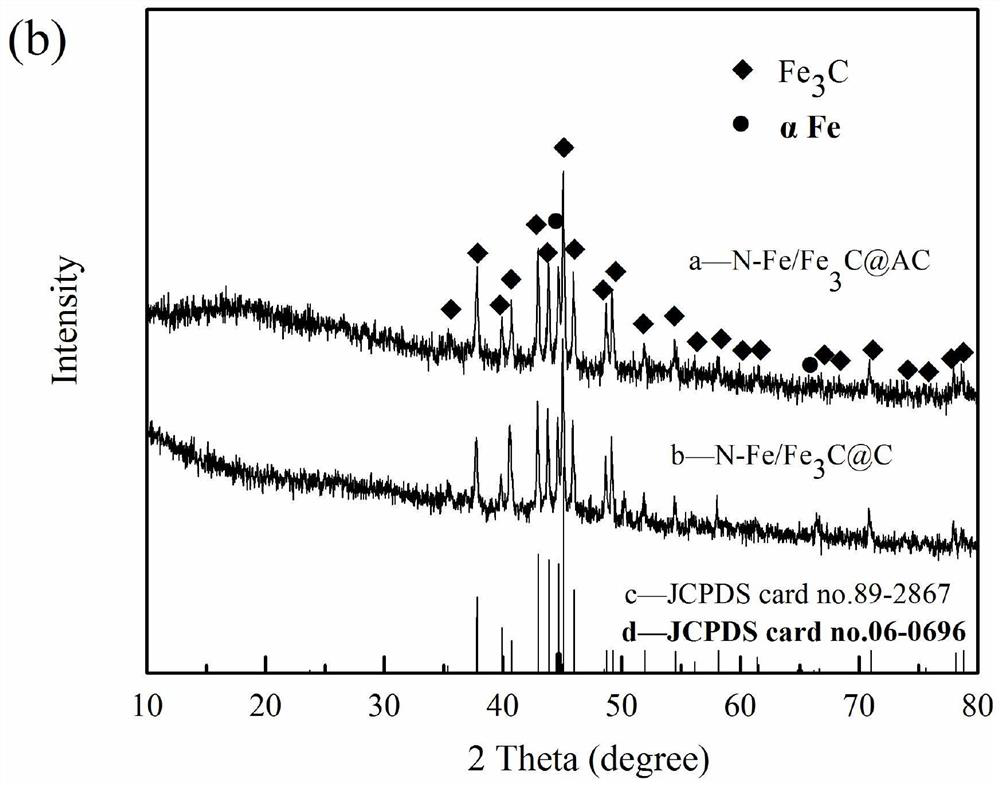

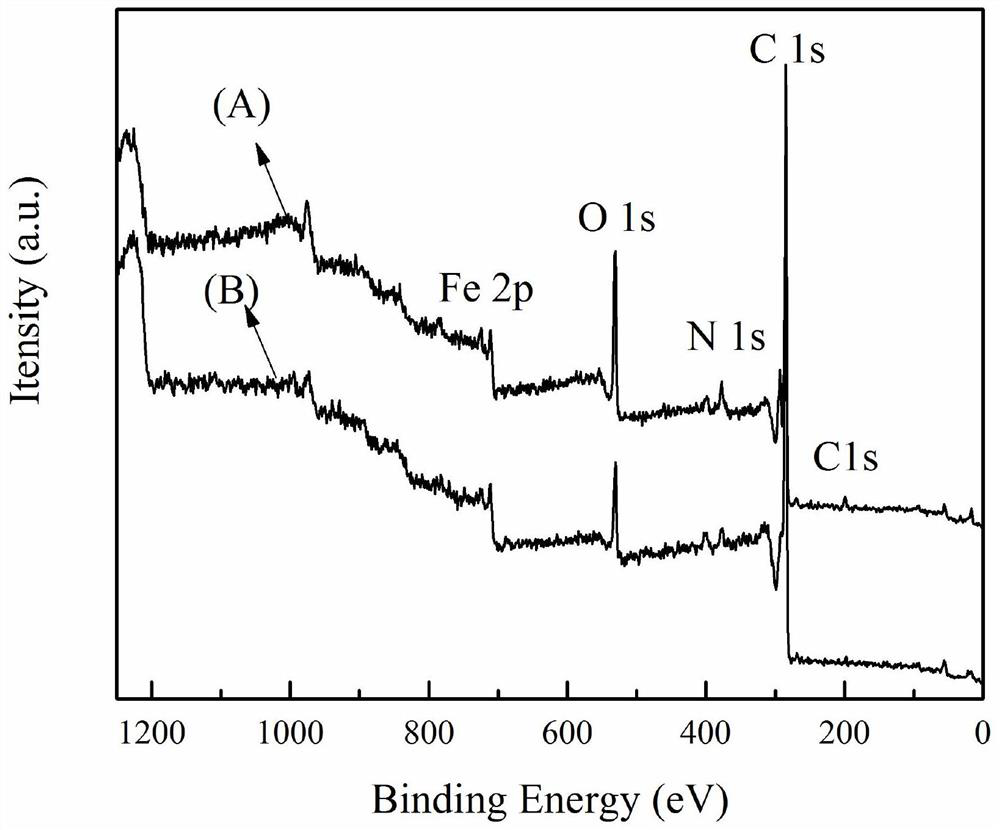

[0038](5) Place the product PB @ AC obtained by step (4) in the tube furnace, first toned at 3 ° C / min at a tempe...

Embodiment 2

[0041]N-Fe / FEC3The preparation method of @AC microbial fuel cell air cathode composite electrocatalytic material, including the following steps:

[0042](1) 2G activated Carbon, AC was added to 100 ml of deionized water, and the ultrasonic dispersion was dispersed for 30 min, and uniformly dispersed activated carbon solution, spare;

[0043](2) Potassium 0.0035mol ferride (K4Fe (CN)6· 3h2O) and 1G Polyvinylpyrrolidone (PVP) ultrasonic dispersion in the solution obtained by step (1), after the force is stirred for 3 h;

[0044](3) Slowly drop 100ml 0.0466mol·L to the solution obtained from step (2)-1Iron chloride (FECL3· 6h2O) The solution was continued for 4 h, followed by static treatment at room temperature 24h;

[0045](4) Other implementation steps are the same as in Example 1.

[0046]The resulting composite procedure N-Fe / FEC3In the middle product of @AC PB @ AC, the mass ratio of AC and PB is 2: 1.

Embodiment 3

[0048]N-Fe / FEC3The preparation method of @AC microbial fuel cell air cathode composite electrocatalytic material, including the following steps:

[0049](1) 2G activated Carbon, AC was added to 100 ml of deionized water, and the ultrasonic dispersion was dispersed for 30 min, and uniformly dispersed activated carbon solution, spare;

[0050](2) Potassium 0.0071 mol ferride (K4Fe (CN)6· 3h2O) and 1G Polyvinylpyrrolidone (PVP) ultrasonic dispersion in the solution obtained by step (1), after the force is stirred for 3 h;

[0051](3) Slowly drop 100ml 0.094mol·L to the solution obtained from step (2)-1Iron chloride (FECL3· 6h2O) The solution was continued for 4 h, followed by static treatment at room temperature 24h;

[0052](4) Other implementation steps are the same as in Example 1.

[0053]The resulting composite procedure N-Fe / FEC3In the middle product of @AC, the mass ratio of AC and PB is 1: 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com