Insulating spider resistant to electrical carbon mark

A technology of electric carbon trace and insulating support, which is applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of poor electric resistance carbon trace insulation, cracked surface of injection support sleeves, grains or bubbles, etc., to achieve insulation The effect is good, the appearance quality is good, and the effect of increasing the safety distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

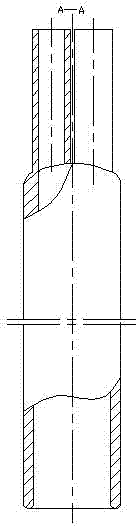

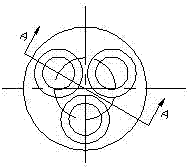

Image

Examples

Embodiment 1

[0019] Example 1: The insulation support sleeve for electric carbon marks contains: 5 kg of low-density polyethylene, 8 kg of polyethylene-vinyl acetate, 0.10 kg of antioxidant 1010, and the flame retardant is melamine cyanurate and melamine isocyanate A total of 2.5 kg of cyanurate, including 1.5 kg of melamine cyanurate, 1 kg of melamine isocyanurate, 0.5 kg of polymer wax, 7 kg of magnesium hydroxide micropowder, and 0.5 kg of color masterbatch or iron oxide red.

Embodiment 2

[0020] Example 2: The insulating support sleeve of electric carbon trace resistance contains: 8 kg of low-density polyethylene, 10 kg of polyethylene-vinyl acetate, 0.15 kg of antioxidant 1010, melamine cyanurate and melamine isocyanurate A total of 5kg, polymer wax 0.75kg, zinc stearate 0.1kg, magnesium hydroxide micropowder 3.5kg, color masterbatch or iron oxide red 0.5kg.

Embodiment 3

[0021] Example 3: The insulating support sleeve for electric carbon traces contains: 10 kg of low-density polyethylene, 12 kg of polyethylene-vinyl acetate, 0.20 kg of antioxidant 1010, and melamine cyanurate and melamine isocyanate as flame retardants. 4 kg of cyanurate each, 8 kg in total, 1 kg of polymer wax, 0.2 kg of zinc stearate, 0.6 kg of color masterbatch or iron oxide red.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com