Technology for continuously producing nitrocompound fertilizer by using low-grade phosphorus ore and dolomite

A dolomite, low-grade technology, applied in application, fertilizer form, fertilization device, etc., to achieve the effects of strong operability, reduced environmental pollution, and high calcium and magnesium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

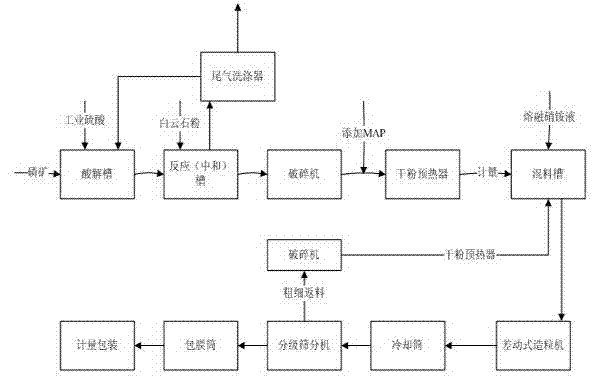

Method used

Image

Examples

Embodiment 1

[0028] Calculated according to the production of one ton of compound fertilizer batching reaction production:

[0029] Take 250Kg of phosphate rock, add no more than 35Kg of water for wetting, then add 40Kg of concentrated sulfuric acid with an appropriate fraction of 98% for reaction, and recover and treat the tail gas after the reaction. After about 2 hours, add 160Kg of dolomite, and add no more than 15Kg After about 1 hour, use a pulverizer to crush, then add an appropriate amount of ammonium phosphate, send it to the granulation tower with a bucket elevator, heat the mixture to nearly 80°C, add ammonium nitrate solution in proportion, and control the reaction temperature. At 140°C, the viscosity of the slurry is suitable at this time. It is granulated by a granulator, convects with the air, shrinks into round particles in the tower and falls, collects, cools, adds anti-caking oil and powder, and packs the finished product. In the finished product: the mass percentage of N...

Embodiment 2

[0033] Take 350Kg of phosphate rock, add no more than 45Kg of water to moisten it, then add 40Kg of concentrated sulfuric acid to react, recover and treat the tail gas, and discharge the waste gas. After about 2 hours, use a pulverizer to crush it, add an appropriate amount of ammonium phosphate, and send it to Go to the prilling tower, heat the mixture to nearly 80°C, and add ammonium nitrate solution in proportion (there are specific data here, what is the proportion here, if it is a prescribed formula, what is the national regulation?) Control the reaction temperature to At 150°C, the viscosity of the slurry is appropriate at this time. Use a granulator to granulate, form convection with the air, shrink into round particles in the tower and fall, collect and cool, add anti-caking oil and powder, and pack the finished product. The mass percent content of detected N was 20.52%, P 2 o 5 The mass percentage of Ca is 5.05%, and the mass percentage of Ca is 6.87%. At this time, ...

Embodiment 3

[0036] According to the production of one ton of compound fertilizer batching reaction production:

[0037]Take 100Kg of phosphate rock, add no more than 35Kg of water to moisten it, add 40Kg of concentrated sulfuric acid to react, and recover and treat the tail gas. After about 2 hours, add 160Kg of dolomite, add no more than 15Kg of water to moisten it, and after about 1 hour, crush it with a pulverizer, add An appropriate amount of ammonium phosphate is sent to the granulation tower with a bucket elevator, the mixture is heated to nearly 80°C, and ammonium nitrate solution is added in proportion to control the reaction temperature at 160°C. The viscosity of the slurry is suitable, and the granulator granulates to form convection with the air , shrink into round particles in the tower and fall, collect and cool, add anti-caking oil and powder, and pack the finished product. The mass percentage of N detected was 21.32%, P 2 o 5 The mass percentage composition of Ca is 9.13%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com