Zirconium-containing copper silver titanium solder alloy

A technology of titanium brazing filler metal and brass alloy, which is applied in the fields of copper-silver alloys and copper-silver-titanium brazing filler metals containing zirconium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0031] In the embodiment of the present invention, different contents of zirconium are added to the ingredients of copper-silver-titanium alloy (Ag: 10~45%, Ti: 1~4%, the balance is Cu), and its composition is different from the existing Ag71Cu27.5Ti1 .5 and other cast copper-silver-titanium alloys, the alloy ingredients of Examples 1, 2, 3, 4, 5 and comparative examples are shown in Table 1. The alloys of Examples and Comparative Examples were prepared by vacuum melting and casting into round billets under the protection of argon. The vacuum melting temperature is 1200~1500℃, and the vacuum degree is 0.001~0.1 Pa; the specific instructions are as follows:

Embodiment 1

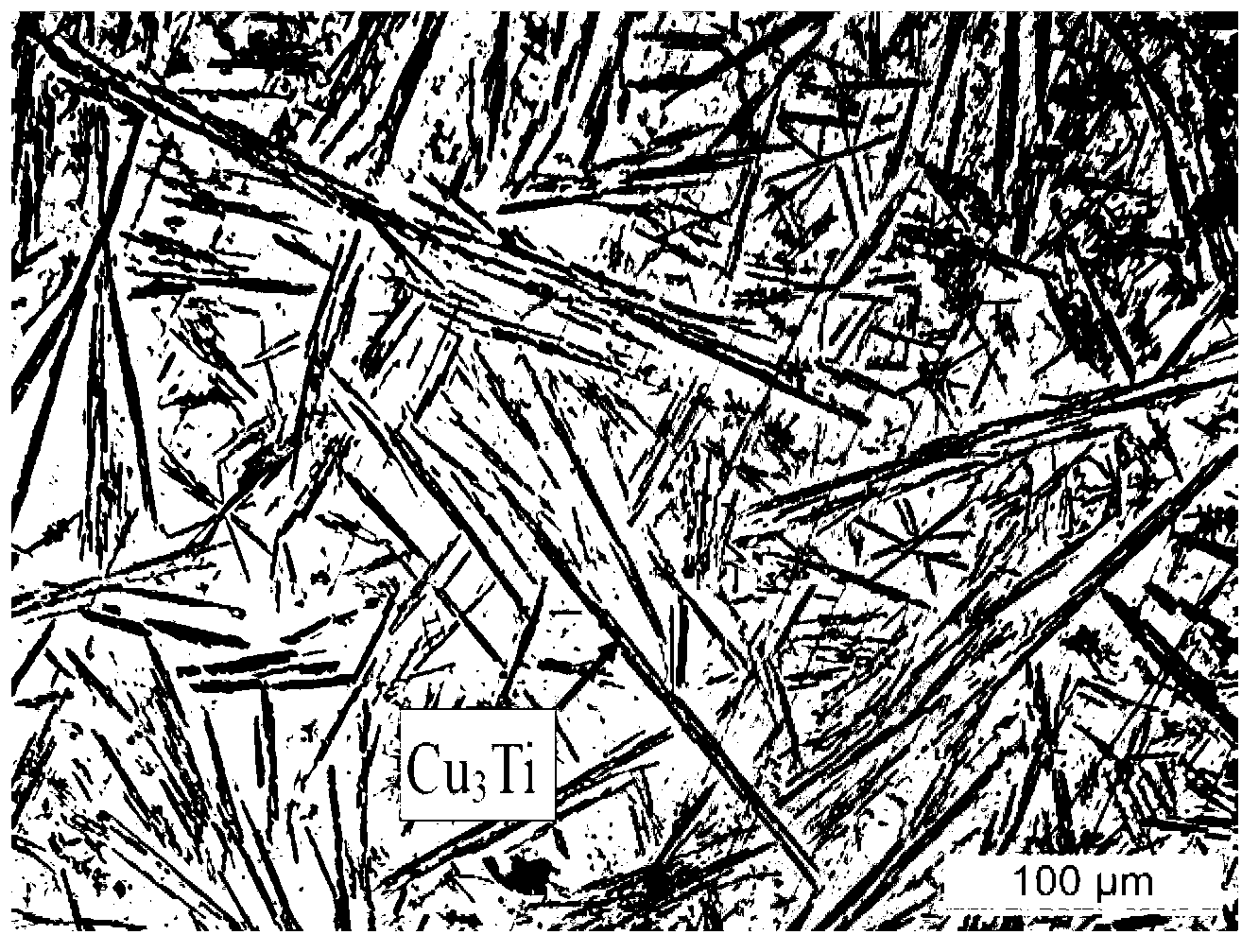

[0035] Alloy ingredients (raw materials: pure silver, electrolytic copper, sponge titanium, Cu-50Zr master alloy) are melted in a vacuum induction melting furnace, and cast into ingots under argon protection. The melting point of the solder alloy is 781°C, and the Vickers hardness is 178HV. The solder alloy is used in the connection of brass alloy materials. The shear strength test shows that the shear strength of the solder joint is 81MPa, the solder and the solder material are well wetted, and there is no Cu on the interface between the solder and the solder material. 3 Ti phase is enriched.

Embodiment 2

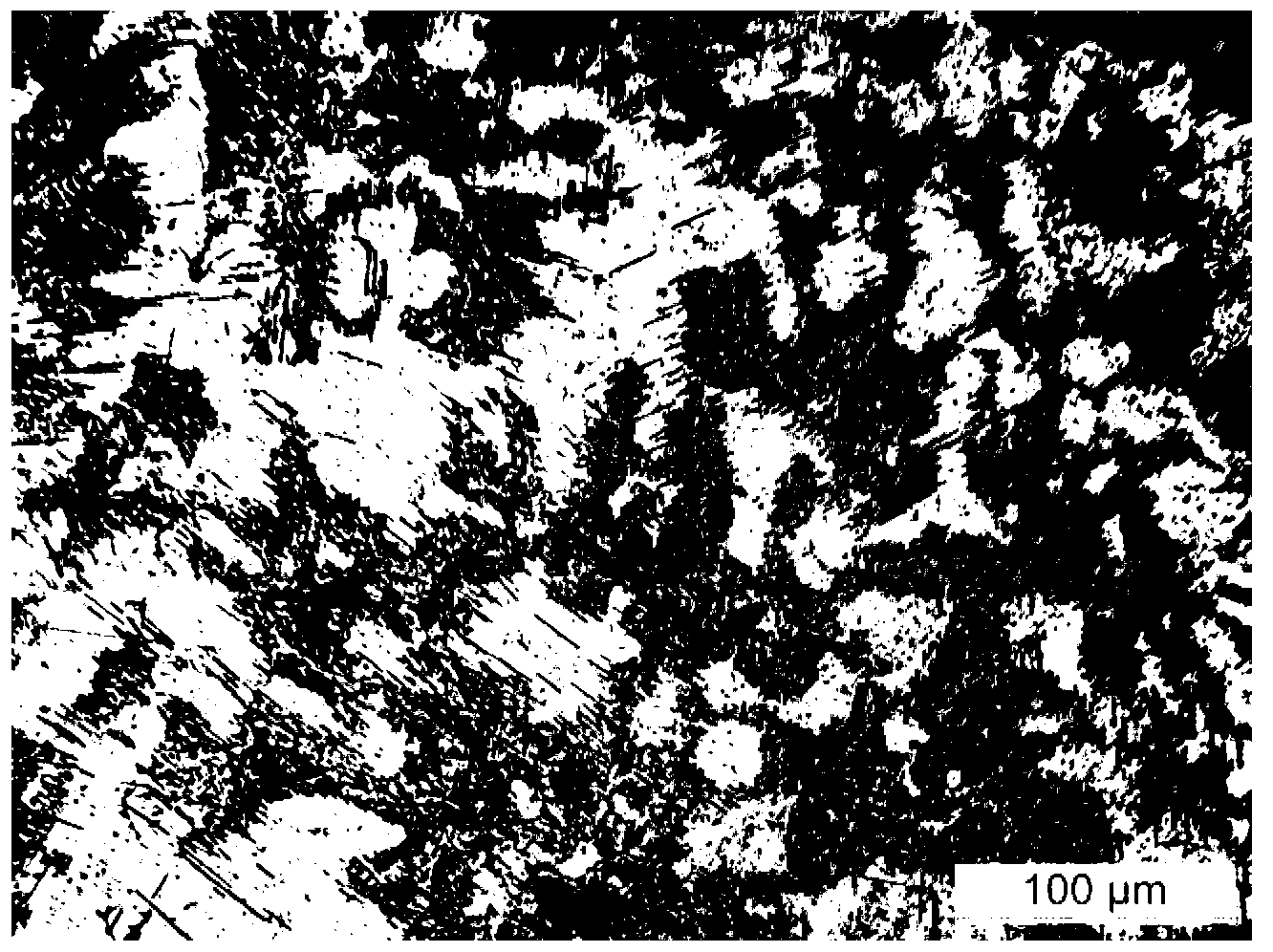

[0037] Alloy ingredients (raw materials: pure silver, electrolytic copper, sponge titanium Cu-50Zr master alloy) are melted in a vacuum induction melting furnace, and cast into ingots under argon protection. figure 2 . The melting point of the solder alloy is 786°C, and the Vickers hardness is 198HV. The solder alloy is used in the connection of brass alloy materials. The shear strength test shows that the shear strength of the solder joint is 96MPa, the solder and the solder material are well wetted, and there is no Cu on the interface between the solder and the solder material. 3 Ti phase is enriched.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com