Hydrothermal synthesis method for nanowire/stick-like morphology manganese lithium silicate

A technology of hydrothermal synthesis, lithium manganese silicate, applied in structural parts, electrical components, battery electrodes, etc., to achieve wide application prospects, improved battery charge and discharge performance, and improved electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

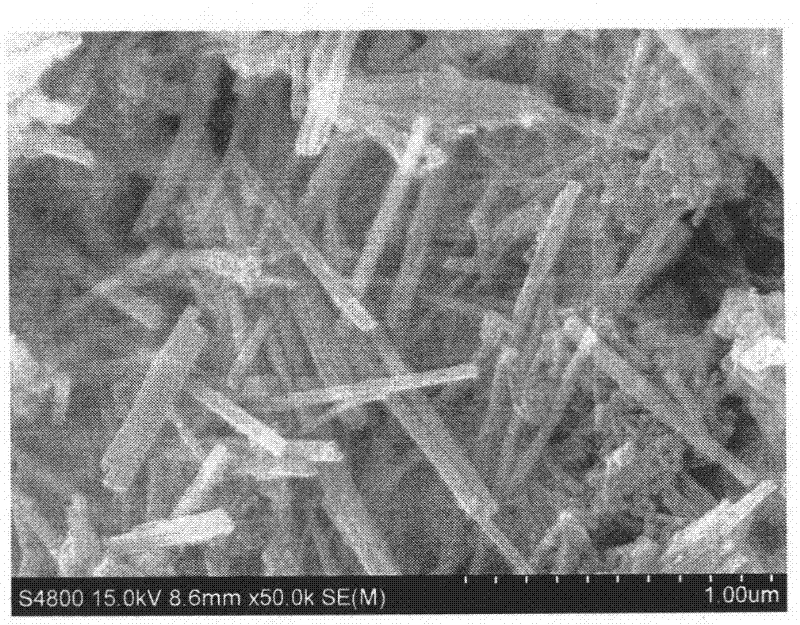

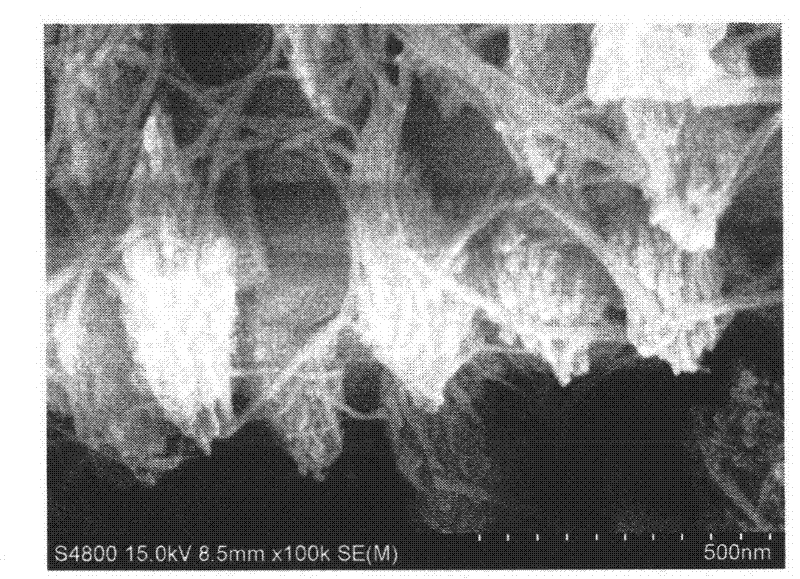

Embodiment 1

[0026] Weigh 0.12 moles of lithium hydroxide monohydrate, 0.015 moles of each of manganese acetate tetrahydrate and ethyl orthosilicate, LiOH·H 2 O:Mn(Ac) 2 ·4H 2 O: Ethyl orthosilicate = 8: 1: 1, put it into a ball mill, add 10wt% PVA and deionized water, and mill it at a speed of 150 rpm for 10 minutes; then pour the mixed liquid into a polytetrafluoroethylene In a stainless steel reactor lined with vinyl fluoride (volume 100ml), deionized water was added to form a liquid capacity of 80ml (80 vol%). It was sealed and placed in a homogeneous reactor, and the crystallization reaction was carried out at 200° C. for 72 hours at a speed of 10 rpm. After the reaction was completed, the reactor was taken out and cooled to room temperature. Wash with alcohol and deionized water, filter, and dry to obtain a hydrothermal crystallization product; in a high-purity nitrogen atmosphere, calcine at 550 °C for 8 hours to obtain Li 2 MnSiO 4 powder. The first discharge capacity reaches...

Embodiment 2

[0028] Weigh 0.03 mole of lithium hydroxide monohydrate, 0.015 mole of each of manganese acetate tetrahydrate and ethyl orthosilicate, LiOH·H 2 O:Mn(Ac) 2 ·4H 2 O: ethyl orthosilicate = 2: 1: 1, put it in a ball mill jar, add 20wt% PVA and deionized water, and ball mill at a speed of 160 rpm for 10 minutes; then pour the mixed solution into a polytetrafluoroethylene In a stainless steel reactor lined with vinyl fluoride (volume 100ml), deionized water was added to form a liquid volume of 70ml (accounting for 70vol%). It was sealed and placed in a homogeneous reactor, and the crystallization reaction was carried out at 180° C. for 48 hours at a speed of 20 rpm. After the reaction was completed, the reactor was taken out and cooled to room temperature. Wash with alcohol and deionized water, filter, and dry to obtain a hydrothermal crystallization product; in a high-purity argon atmosphere, calcine at 650 °C for 10 h to obtain Li 2 MnSiO 4 powder. The first discharge capaci...

Embodiment 3

[0030] Weigh 0.09 moles of lithium hydroxide monohydrate, 0.015 moles of each of manganese acetate tetrahydrate and ethyl orthosilicate, LiOH·H 2 O:Mn(Ac) 2 ·4H 2 O: ethyl orthosilicate = 6: 1: 1, put it into a ball mill jar, add 15wt% PVA and deionized water, and mill it at a speed of 170 rpm for 10 minutes; then pour the mixed solution into a polytetrafluoroethylene In a stainless steel reaction kettle lined with vinyl fluoride (volume 100ml), supplemented with deionized water to form a liquid capacity of 60ml (accounting for 60vol%). It was sealed and put into a homogeneous reactor, and the crystallization reaction was carried out at 220° C. for 24 hours at a rotation speed of 30 rpm. After the reaction was completed, the reactor was taken out and cooled to room temperature. Wash with alcohol and deionized water, filter, and dry to obtain a hydrothermal crystallization product; in a high-purity argon atmosphere, calcinate at 750 °C for 5 hours to obtain Li 2 MnSiO 4 po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com