Production method for soluble starch

A production method and soluble technology, which is applied in the field of soluble starch production, can solve problems such as difficulty in grasping the degree of starch degradation and difficult centrifugation, and achieve the effects of improved reaction efficiency, good solubility, and simple reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

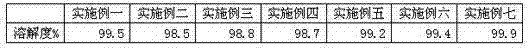

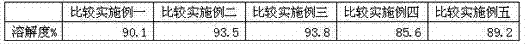

Embodiment 1

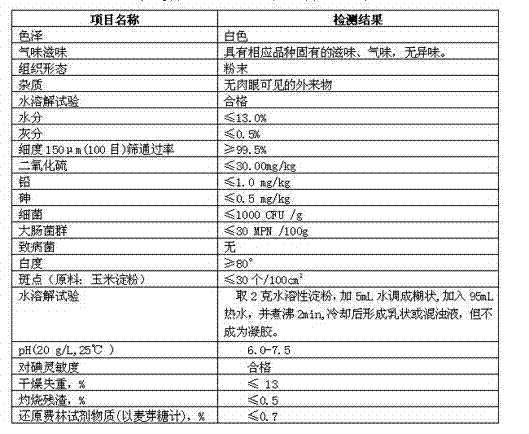

[0028] Add cornstarch (bulk density 0.5-0.6g / cm2) into a 3000-liter enamel rotary vacuum dryer (equipped with circulating water heating jacket, thermometer, air inlet, air inlet, and vacuum gauge) 3 ) 800kg, heat the jacket with water at 60°C, evacuate to -0.09MPa, put in dry hydrogen chloride, stop putting in hydrogen chloride when the vacuum degree is -0.03Mpa, and calculate the amount of hydrogen chloride to be introduced as 160-400g. Heat and rotate at 60°C for 3 hours. Vacuum down to below -0.09Mpa and keep for 30 minutes, pass through ammonia gas to neutralize to pH6.0-7.5, continue vacuuming for about 30 minutes, pulverize to get finished products, and take samples for testing.

[0029] The blue color detected by the potassium iodide indicator indicates that the starch has been degraded, the hydrogen chloride is not excessive, and the obtained finished product is soluble. And if it turns red with potassium iodide indicator, it means excess hydrogen chloride.

[0030] ...

Embodiment 2

[0037] React 1000kg of potato starch with a water content of 8-15% and 0.2kg of dry hydrogen chloride in a fluidized bed reactor at a temperature of 10°C and a vacuum of -0.001MPa for 0.5h, and keep it warm for 0.3-0.8h to obtain acid-soluble starch. Then use potassium bicarbonate to neutralize the acid soluble starch to pH 6.0-7.5 to obtain neutral soluble starch, and finally pulverize to obtain the finished product.

Embodiment 3

[0039] First add 1000kg of cassava starch with a water content of 10-12% into the enamel reaction kettle, then vacuumize to -0.08~-0.095MPa, then feed 0.5kg of dry hydrogen chloride, and stop the drying when the vacuum degree is -0.005MPa React hydrogen chloride at 80°C for 5 hours, keep warm for 0.8 hours to obtain acid-soluble starch, then use sodium bicarbonate to neutralize the acid-soluble starch to pH 6.0-7.5, then vacuumize for 0.8 hours, and finally pulverize to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com