Waste water treatment system

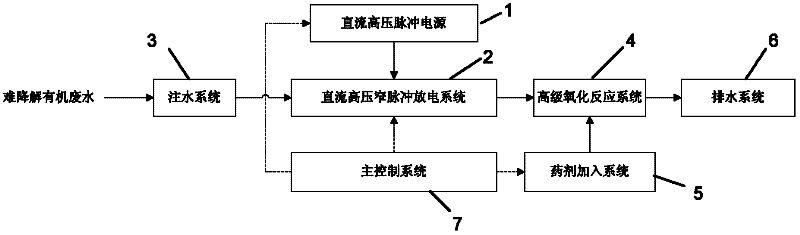

A technology of wastewater treatment system and water injection system, which is applied in the field of wastewater treatment system of plasma technology, can solve problems such as difficult maintenance of equipment, short circuit of discharge circuit, and impossibility of industrial application, so as to eliminate algal microbial pollution, improve B/C ratio, The effect of improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

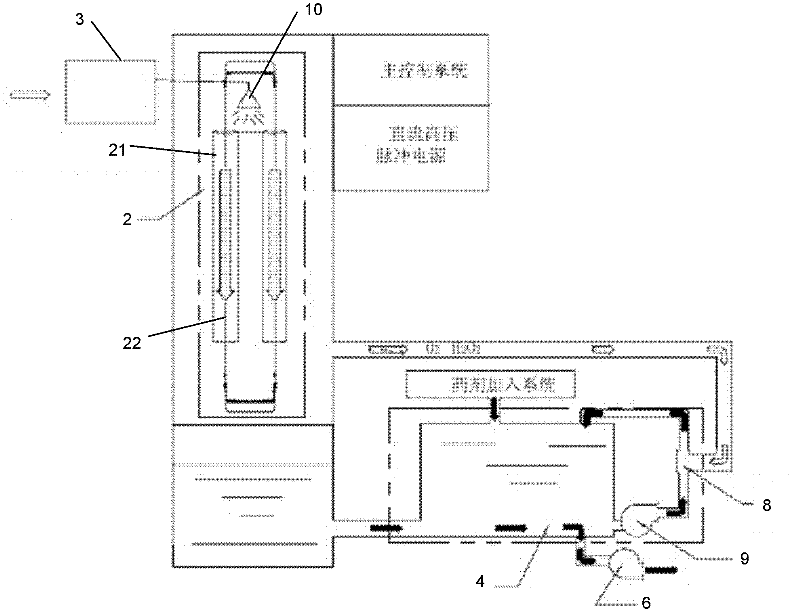

Method used

Image

Examples

Embodiment 1

[0053] Nitrobenzene wastewater from a pesticide factory, after determination, wastewater COD=310037, BOD 5 =105851, B / C=0.15, pH=8. Treatment process: DC voltage 40000V, discharge frequency 500 times / second, water flow rate 140L / min, quickly pass through the DC high-voltage narrow pulse discharge system, combined with the deep oxidation of the advanced oxidation reaction system 4, the B / C ratio is significantly improved. The processing results are as follows:

[0054]

Embodiment 2

[0056] Phenol wastewater from a pesticide factory B, after determination, wastewater COD = 133085, BOD 5 =105851, B / C=0.1, pH=8. Treatment process: Fe is added to the waste liquid 2+ 40mg / l, DC voltage 50000V, discharge frequency 700 times / s, water flow rate 200L / min, fast through the DC high-voltage narrow pulse discharge system, combined with the deep oxidation of the advanced oxidation reaction system 4, the B / C has been significantly improved. The processing results are as follows:

[0057]

Embodiment 3

[0059] A landfill leachate, COD=55000, treatment process: DC voltage, 48000V, discharge frequency 900 times / second, water flow rate 50L / min, quickly pass through the DC high-voltage narrow pulse discharge system, combined with advanced oxidation reaction system 4 With deep oxidation, the removal rate of COD is significantly improved, and the odor intensity of wastewater after treatment is greatly reduced. The processing results are as follows:

[0060]

[0061] In summary, after being treated by the wastewater treatment system of the present invention, the COD and BOD in the water can be greatly reduced, the amount of sludge produced can be reduced, and favorable conditions are also provided for the subsequent biochemical treatment to reduce the amount of activated sludge, thereby greatly reducing sewage treatment sludge. The amount of mud produced is economical and environmentally friendly.

[0062] And the wastewater treatment system of the present invention also has the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com