Dust cup filter and dust collector provided with same

A filter and dust cup technology, used in vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problems of small filtering area, complex structure design, insufficient suction, etc., to increase the air passage area, improve the filtering efficiency, and simplify the overall effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

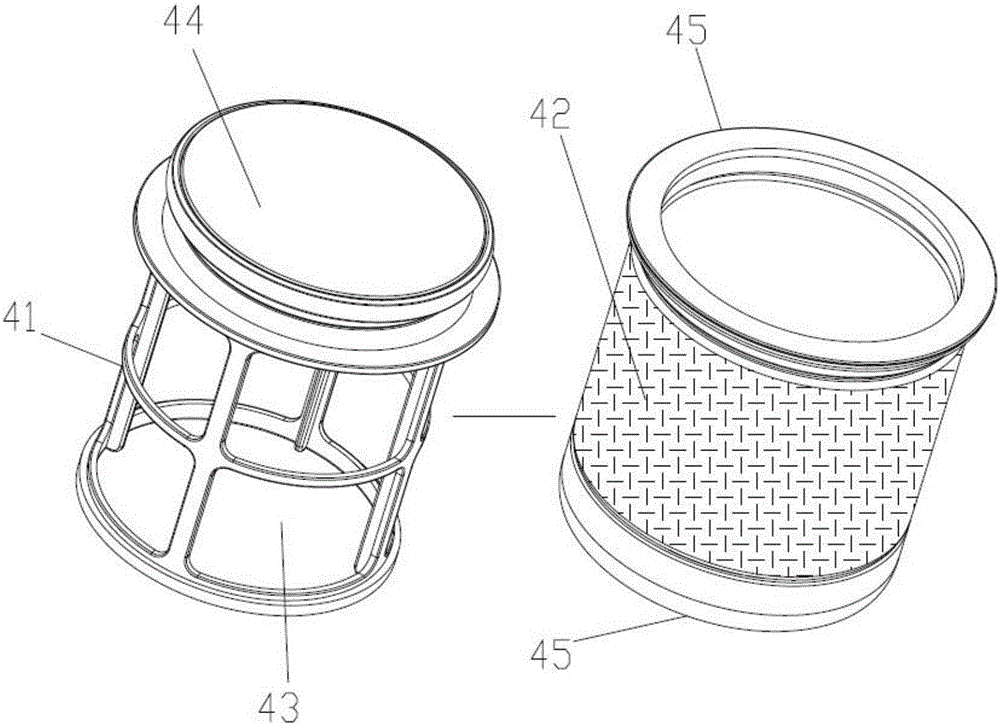

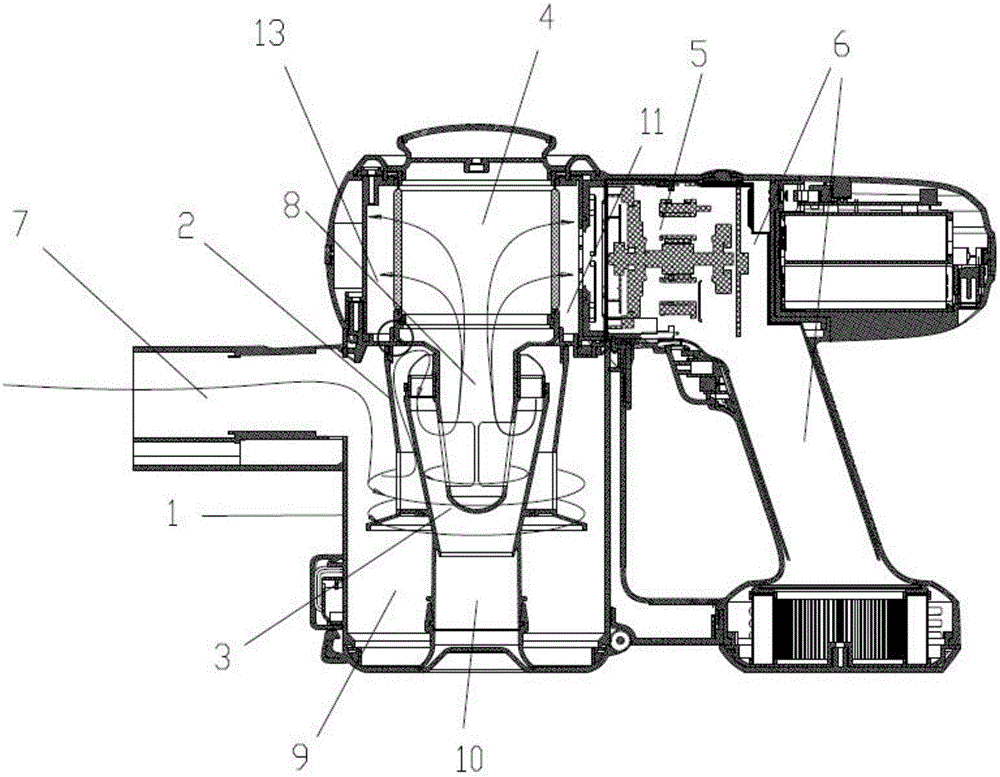

[0030] As mentioned in the background technology section, the filter device in the prior art is a circular flat filter cotton with a small filter area, and the filter cotton is arranged inside the dust cup, and the dust cup cover needs to be opened before taking it, which is inconvenient to operate .

[0031] Aiming at the deficiencies in the prior art, the present invention provides a dust cup filter. By changing the air intake mode of the filter, the dust gas separated by the cyclone dust gas separation device directly enters the interior of the filter upward and axially, and is passed Radial discharge can effectively shorten the dust flow path; by changing the structure of the filter, the side of the cylindrical structure is used as the filter surface to more effectively increase the air passing area, reduce pressure loss, improve filtration efficiency, and simplify the overall structure ,cut costs.

[0032] The technical solutions of the present invention will be clearly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com