Air conditioner boiling vessel

A technology for a cooker and an air conditioner, which is used in air conditioning systems, steam cooking utensils, space heating and ventilation, etc., can solve the problems of low electric-heat conversion efficiency, uneconomical, waste of energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

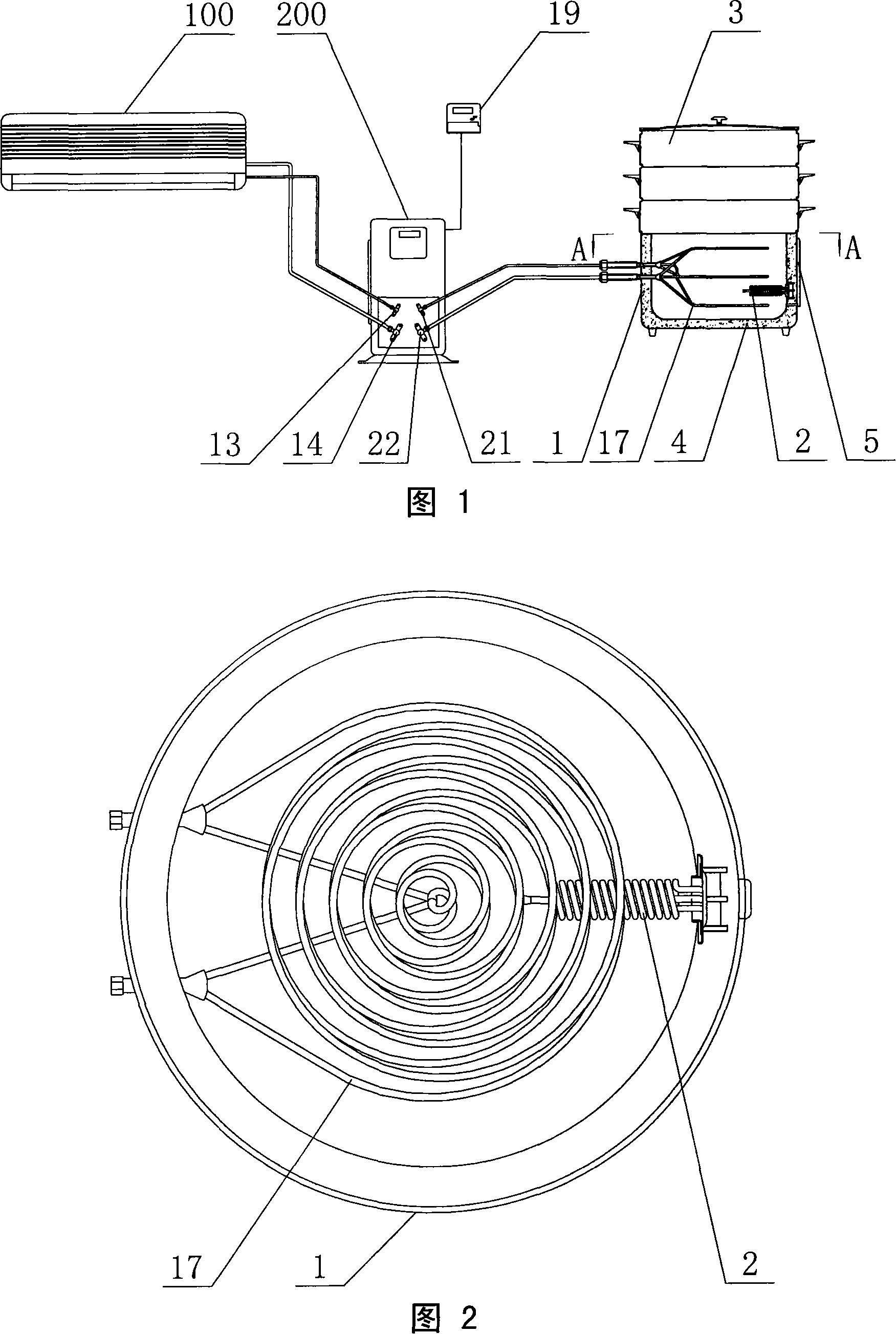

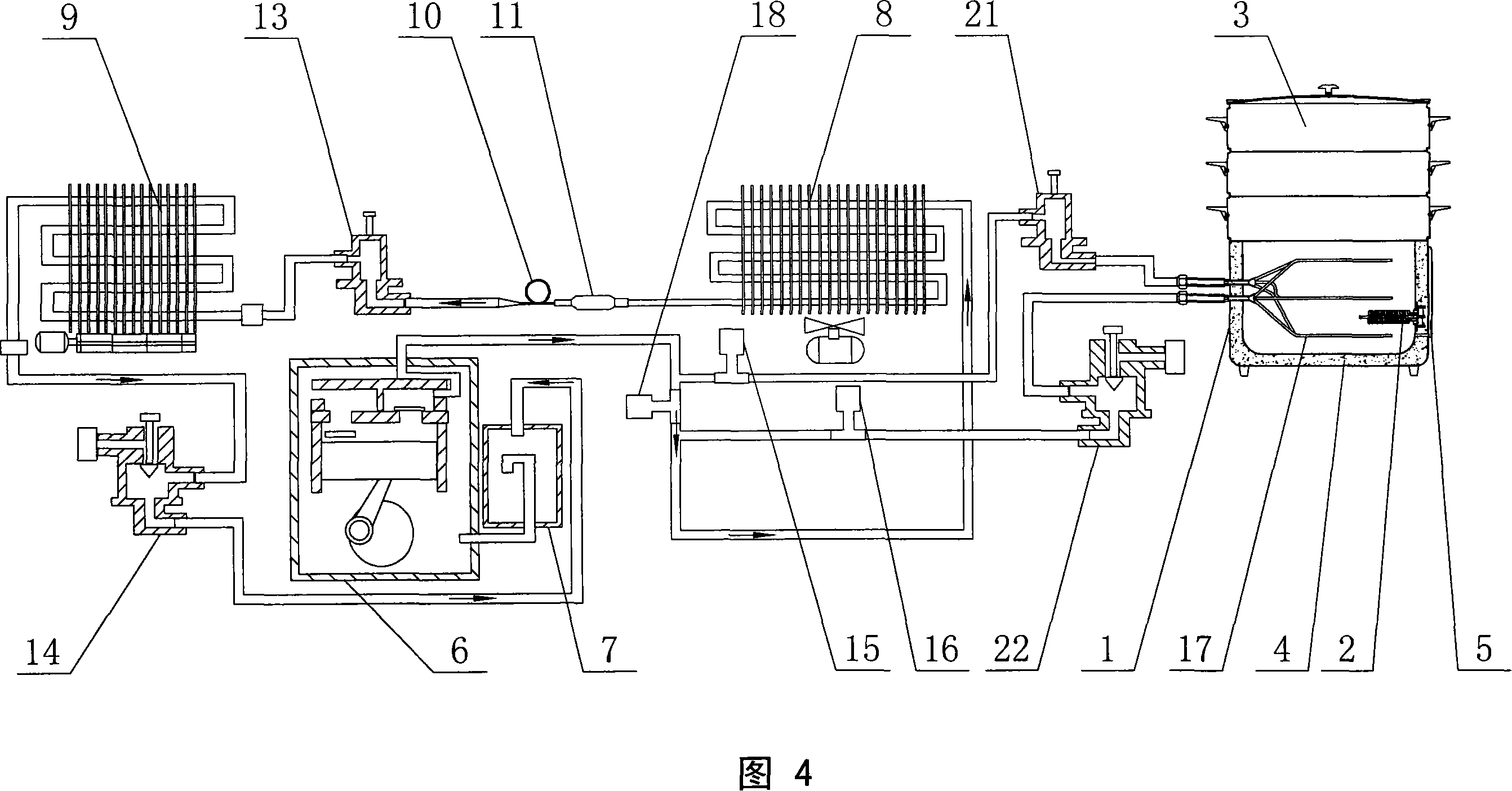

[0029] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4, the present invention comprises air conditioner, steamer 1, steamer 3, water condenser 17, III stop valve 21, IV stop valve 22, controller 19, described steamer The pot 1 is provided with an electric heating pipe type electric heater 2 and an insulation layer 4, and the outside of the steamer 1 is provided with a water gauge 5; the air conditioner includes an indoor casing 100, an outdoor casing 200, a compressor 6, and a heat Exchanger 8, throttling device 10, I cut-off valve 13, II heat exchanger 9, II cut-off valve 14, gas-liquid separator 7, the outlet of the compressor 6 is sequentially connected to the III cut-off through the refrigerant pipeline Valve 21, the water condenser 17, the IV cut-off valve 22, the I heat exchanger 8, the throttling device 10, the I cut-off valve 13, the II heat exchanger 9, the II The stop valve 14, the gas-liquid separator 7 are connected back to the inlet of the compressor 6 to form a circul...

Embodiment 2

[0034] As shown in Fig. 1, Fig. 2, Fig. 5, Fig. 6, Fig. 7, Fig. 8, the present invention comprises air conditioner, steamer 1, steamer 3, water condenser 17, III stop valve 21, IV stop valve 22, control device 19, the steamer 1 is provided with an electric heating tube electric heater 2 and an insulating layer 4, and the steamer 1 is provided with a water level gauge 5; the air conditioner includes an indoor casing 100, an outdoor casing 200, Compressor 6, four-way valve 12, I heat exchanger 8, throttling device 10, I stop valve 13, II heat exchanger 9, II stop valve 14, gas-liquid separator 7, the outlet of the compressor 6 passes through The refrigerant pipeline is sequentially connected to the III cut-off valve 21, the water condenser 17, the IV cut-off valve 22, the inlet A of the four-way valve 12, the I inlet and outlet C of the four-way valve 12, The I heat exchanger 8, the throttling device 10, the I cut-off valve 13, the II heat exchanger 9, the II cut-off valve 14, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com