Method of cleaning molten steel with multi-foam screen of continuously casted tundish

A continuous casting tundish and clean steel technology, which is applied to casting equipment, casting molten material containers, manufacturing tools, etc., can solve the problems of low non-metallic inclusion removal rate, failure to meet production requirements, limited size and distribution, etc., to achieve Avoid the problem of molten steel cooling and slag entrainment, avoid the problem of easy adsorption saturation and failure, and the effect of long-term removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

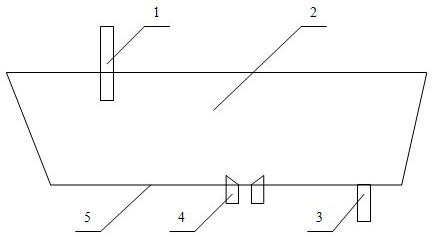

[0017] The invention discloses a method for cleaning molten steel with multiple air bubble curtains in a continuous casting tundish. like figure 1 As shown, two breathable bricks 4 are arranged on the bottom 5 of the tundish 2, and the distance between the breathable bricks 4 is 300-500mm. The center distance between the air brick 4 and the water outlet 3 is 500-600mm.

[0018] Before the tundish 2 is poured, argon gas is introduced through the breathable brick 4, the flow rate of the argon blowing is 5~8Nl / min, and the pressure is 0.02~

[0019] 0.03MPa; when the tundish 2 is poured, adjust the argon blowing flow rate to 7~15Nl / min, and the pressure to 0.08~0.11MPa.

Embodiment 2

[0022] The invention discloses a method for cleaning molten steel with multiple air bubble curtains in a continuous casting tundish. like figure 1 As shown, three air-permeable bricks 4 are arranged on the bottom 5 of the tundish 2, and the distance between the air-permeable bricks 4 is 100-300mm. The center-to-center distance between the air-permeable brick 4 and the water outlet 3 is 400-500 mm.

[0023] Before the tundish 2 is poured, argon gas is introduced through the air-permeable brick 4, the argon blowing flow rate is 6~9Nl / min, and the pressure is 0.03~0.04MPa; min, the pressure is 0.10~0.13MPa.

[0024] Among the three air permeable bricks 4 described in this embodiment, two are inclined surface type and one is plane type; one of them is diffuse type air permeable brick, and two are combined type air permeable bricks.

Embodiment 3

[0026] The invention discloses a method for cleaning molten steel with multiple air bubble curtains in a continuous casting tundish. like figure 1 As shown, four air-permeable bricks 4 are arranged on the bottom 5 of the tundish 2, and the distance between the air-permeable bricks 4 is 50-100mm. The center distance between the air brick 4 and the water outlet 3 is 300-400mm.

[0027] Before the tundish 2 is poured, argon gas is introduced through the breathable brick 4, the flow rate of the argon blowing is 7~10Nl / min, and the pressure is 0.04~

[0028] 0.05MPa; when the tundish 2 is poured, adjust the argon blowing flow rate to 13~20Nl / min, and the pressure to 0.12~0.15MPa.

[0029] Among the 4 breathable bricks 4 described in this embodiment, 2 are inclined surface type and 2 are flat type; 1 of them is diffuse type breathable brick, 1 is straight-through hole type breathable brick, and 2 are combined type breathable bricks .

[0030]In this specific embodiment, on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com