Method and device for oxidatively decomposing pollutants in exhaust gases emitted by internal combustion engine with intervention of ultraviolet light

An oxidative decomposition, internal combustion engine technology, applied in exhaust devices, separation methods, internal combustion piston engines, etc., can solve problems such as no effect of purification, inability to purify harmful particulate matter, etc., to reduce emissions, solve particulate matter emissions, and increase catalytic redox. effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

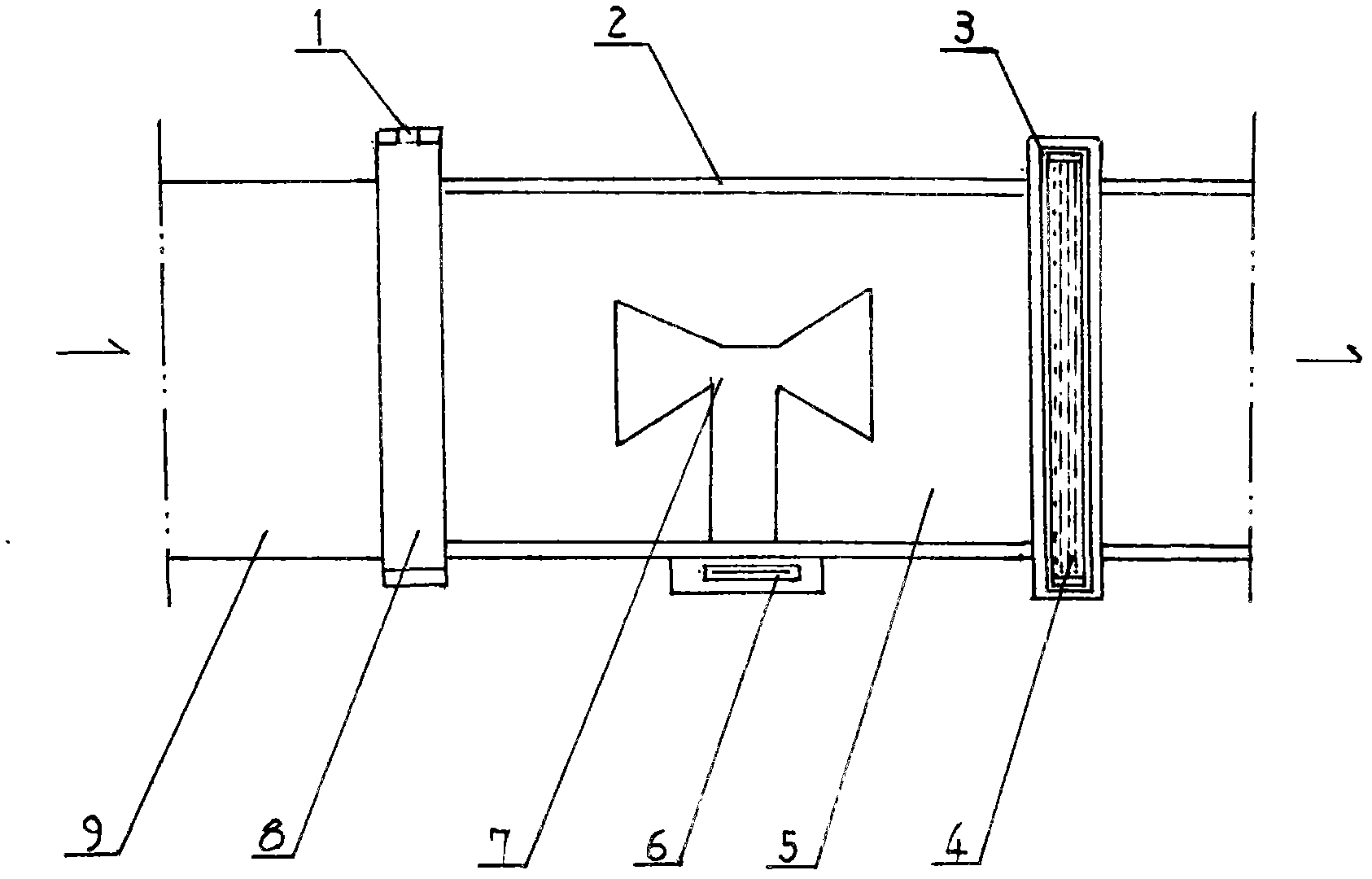

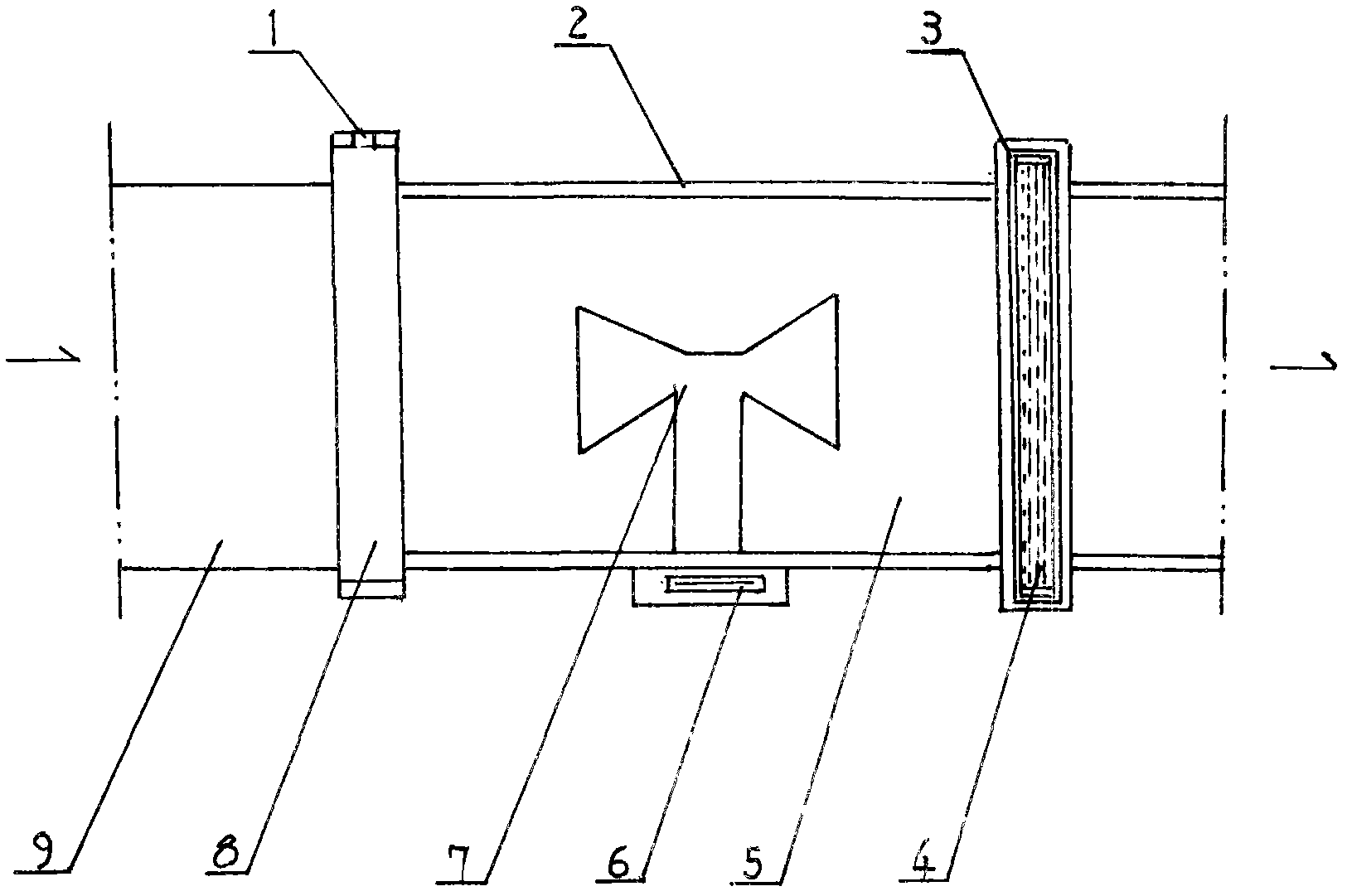

[0015] Such as figure 1 and figure 2 As shown, the method of the present invention is to set at least one ultraviolet light irradiation zone 5 for internal combustion engine exhaust gas to pass through in the internal combustion engine exhaust system, and at least one end of the ultraviolet light irradiation zone is provided with at least one photocatalyst net 4 for internal combustion engine exhaust gas to pass through, so that Ultraviolet light intervenes to oxidize and decompose pollutants in the exhaust gas of internal combustion engines. Including: setting at least one ultraviolet light irradiation area in the exhaust system of the internal combustion engine for the exhaust gas of the internal combustion engine to pass through; The passage for irradiating the light source and allowing the exhaust gas of the internal combustion engine to pass through; at least one end of the ultraviolet light irradiation area is provided with at least one photocatalyst net for the exhaus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com