Method for preparing hexitol or hydroxy-acetone

A technology of hydroxyacetone and hexitol, which is used in the preparation of carbon-based compounds, chemical instruments and methods, and the preparation of hydroxyl compounds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, hydrolysis cellulose prepares hexitol

[0021] Supported Metal Catalyst Pt-SnO x / Al 2 o 3 Preparation: SnCl 2 2H 2 O and H 2 PtCl 6 ·6H 2 O was mixed at a molar fraction ratio of 0.3, then 1 drop of 37% hydrochloric acid solution was added dropwise and water was added, and after a uniform solution was formed, Al was added 2 o 3 ; After drying at room temperature, place it in an oven at 110°C for drying overnight, then successively roast (calculate at 400°C and air atmosphere for 4 hours) and reduce (at 400°C and 20% H 2 / N 2 Reduction under the atmosphere of 4 hours) that is.

[0022] 1g of microcrystalline cellulose (microcrystalline cellulose, available from Alfa Aesar) is placed in a 100ml reaction kettle with a sufficient amount of water (50ml), and 0.4g of the 2% prepared above (the mass percent of metal Pt in the active component) is added. content) Pt-SnO x / Al 2 o 3 (Sn / Pt=0.3, x is 0~4), filled with H 2 , the pressure in the reacto...

Embodiment 2

[0034] Embodiment 2, hydrolyzing cellulose to prepare hexitol

[0035] Supported Metal Catalyst Pt-SnO x / Al 2 o 3 Preparation: the specific preparation method is the same as in Example 1, the difference is: SnCl 2 2H 2 O and H 2 PtCl 6 ·6H 2 The molar fraction ratio of O is 0.5.

[0036] 1g of microcrystalline cellulose (microcrystalline, purchased from Alfa Aesar) was placed in a 100ml reaction kettle filled with sufficient water (50ml), and 0.4g of 2% Pt-SnO x / Al 2 o 3 (Sn / Pt=0.5, x is 0~4), filled with H 2 , the pressure in the reactor was 20atm, heated to 240°C, and reacted for 30 minutes.

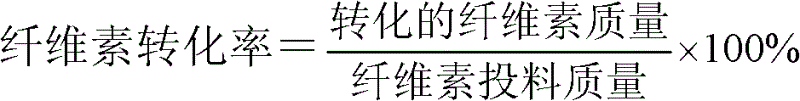

[0037] According to the following method, the conversion rate of cellulose and the selectivity of hexitol were detected:

[0038] The unreacted cellulose was weighed on a balance, and it was 0g; the reaction product was analyzed by high performance liquid phase and quantified (Shimadazu LC-20A HPLC; separation column: BioRad Aminex HPX-87H; analysis conditions: mobile phase...

Embodiment 3

[0041] Embodiment 3, hydrolysis cellulose prepares hydroxyacetone

[0042] Supported Metal Catalyst Pt-SnO x / Al 2 o 3 Preparation: the specific preparation method is the same as in Example 1, the difference is: SnCl 2 2H 2 O and H 2 PtCl 6 ·6H 2 The mole fraction ratio of O was 4.0.

[0043] 1g of microcrystalline cellulose (microcrystalline, purchased from Alfa Aesar) was placed in a 100ml reaction kettle filled with sufficient water (50ml), and 0.4g of 2% Pt-SnO x / Al 2 o 3 (Sn / Pt=4.0, x is 0~4), filled with H 2 , make the pressure in the reactor be 80atm, heat to 200°C, and react for 30 minutes.

[0044] According to the following method, the conversion rate of cellulose and the selectivity of hydroxyacetone are detected:

[0045] The unreacted cellulose was weighed on a balance, and it was 0.779g; the reaction product was analyzed and quantified by high performance liquid phase (Shimadazu LC-20A HPLC; separation column: BioRad Aminex HPX-87H; analysis conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com