Method for preparing brake pad by utilizing ceramic fiber

A technology of ceramic fibers and brake pads, used in mechanical equipment, friction linings, etc., can solve the problems of limited heat resistance, inability to meet use requirements, and brittleness of phenolic resins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

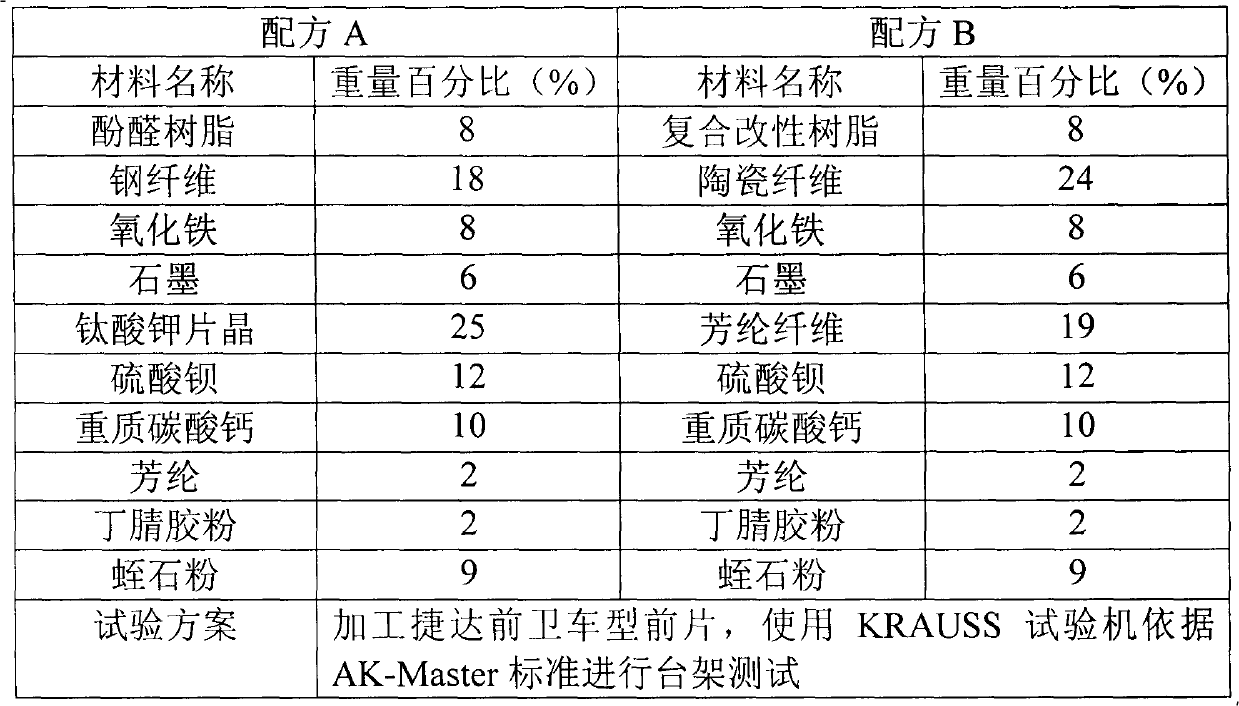

Embodiment 1

[0004] Embodiment 1, the formula of the method for preparing brake pads using ceramic fibers is an adhesive, a reinforcing material, a friction performance regulator and a filler, the adhesive is a composite modified phenolic resin, and the weight percentage of the adhesive is 5%; the reinforcing material is ceramic fiber and aramid fiber, and the weight percentage of the reinforcing material is 20%; the friction modifier includes abrasive and graphite, molybdenum disulfide, mica, and the abrasive Including aluminum oxide, iron oxide, magnesium oxide, the weight percentage of the abrasive is 1%, and the total weight percentage of the graphite, molybdenum disulfide and mica is 5%; the filler is barium sulfate, titanic acid Potassium and vermiculite powder, the weight percentage of the filler is 10%.

Embodiment 2

[0005] Embodiment 2, the formula of the method for preparing brake pads using ceramic fibers is an adhesive, a reinforcing material, a friction performance regulator and a filler, and the adhesive is a composite modified phenolic resin, and the weight percentage of the adhesive is 18%; the reinforcing material is ceramic fiber and aramid fiber, and the weight percentage of the reinforcing material is 30%; the friction modifier includes abrasive and graphite, molybdenum disulfide, mica, and the abrasive Including aluminum oxide, iron oxide, magnesium oxide, the weight percentage of the abrasive is 15%, and the total weight percentage of the graphite, molybdenum disulfide and mica is 15%; the filler is barium sulfate, titanic acid Potassium and vermiculite powder, the weight percentage of the filler is 30%.

Embodiment 3

[0006] Embodiment 3, the formula of the method for preparing brake pads using ceramic fibers is an adhesive, a reinforcing material, a friction performance modifier and a filler, and the adhesive is a composite modified phenolic resin, and the weight percentage of the adhesive is 11%; the reinforcing material is ceramic fiber and aramid fiber, and the weight percentage of the reinforcing material is 25%; the friction modifier includes abrasive and graphite, molybdenum disulfide, mica, and the abrasive Including aluminum oxide, iron oxide, magnesium oxide, the weight percentage of the abrasive is 8%, and the total weight percentage of the graphite, molybdenum disulfide and mica is 10%; the filler is barium sulfate, titanic acid Potassium, vermiculite powder, the weight percent of described filler is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com