Fluorine ion and metal ion-doped cerium oxide-based nanometer ultraviolet shielding material and preparation method thereof

A technology of metal ions and cerium oxide, which is applied in nanotechnology, chemical instruments and methods, and nanotechnology for materials and surface science, can solve problems such as complex preparation process, hidden safety hazards, and difficulties in industrialized and expanded production. Achieve the effect of low oxidation catalytic activity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

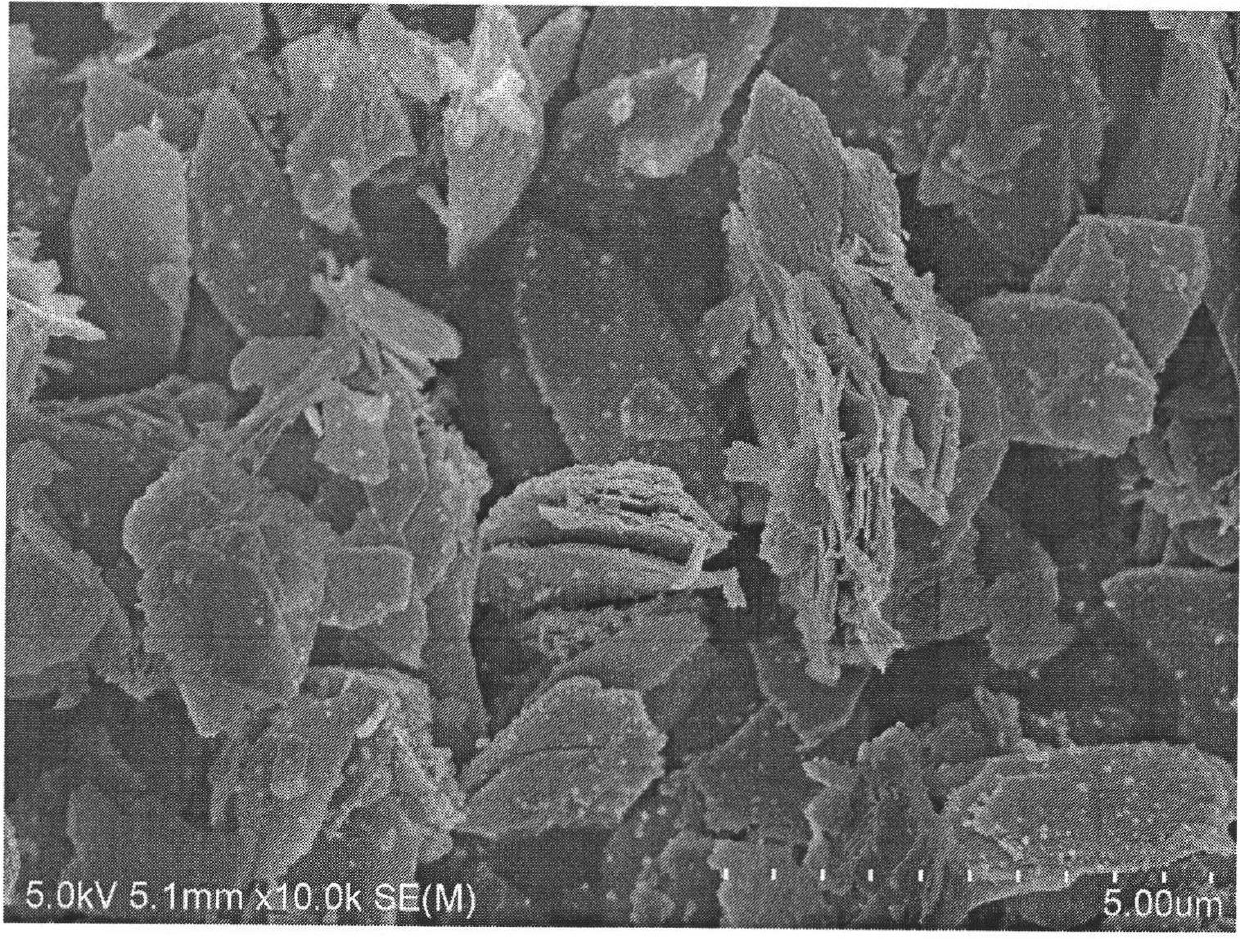

[0063] Embodiment 1: prepare Ce 0.9 Sr 0.1 o 1.82 f 0.16 powder

[0064] Prepare 0.35mol / L cerium nitrate solution and 1mol / L ammonium carbonate solution for use. According to the molar ratio of cerium ion: strontium ion: fluoride ion is 0.9: 0.1: 0.16, take the amount of reactant cerium nitrate, strontium nitrate, ammonium fluoride, mix the obtained cerium nitrate solution with strontium nitrate, stir to obtain strontium , Cerium metal ion mixed solution. Take 2 times the theoretical amount of precipitant ammonium carbonate, mix the ammonium carbonate solution and ammonium fluoride evenly, then drop the mixed solution of strontium and cerium metal ions into it at a constant speed, stir at room temperature for 3 hours, and age for 20 hours after the precipitation is complete to form a slurry After the material was filtered, washed, dried at 100°C for 12 hours, roasted at a constant temperature of 600°C for 5 hours, and cooled to room temperature, the co-doped nano cerium ...

Embodiment 2

[0066] Embodiment 2: preparation Ce 0.8 La 0.2 o 1.75 f 0.3 powder

[0067] Prepare 0.6 mol / L cerium ammonium nitrate solution and 1 mol / L ammonium bicarbonate solution for use. According to the molar ratio of cerium ion: lanthanum ion: fluoride ion is 0.8: 0.2: 0.3, take the amount of reactants cerium ammonium nitrate, lanthanum nitrate, ammonium bifluoride, mix the taken cerium ammonium nitrate solution with lanthanum nitrate, stir to obtain A mixed solution of lanthanum and cerium metal ions. Take 3 times the theoretical amount of precipitant ammonium bicarbonate, mix the ammonium bicarbonate solution and ammonium bifluoride evenly, drop the mixed solution of lanthanum and cerium metal ions into it at a constant speed, control the reaction temperature at about 40°C, stir for 2 hours, and after the precipitation is complete Aging for 10 hours, forming a slurry, filtering, washing, drying at 90°C for 20 hours, calcining at 600°C for 5 hours, and cooling to room temperatu...

Embodiment 3

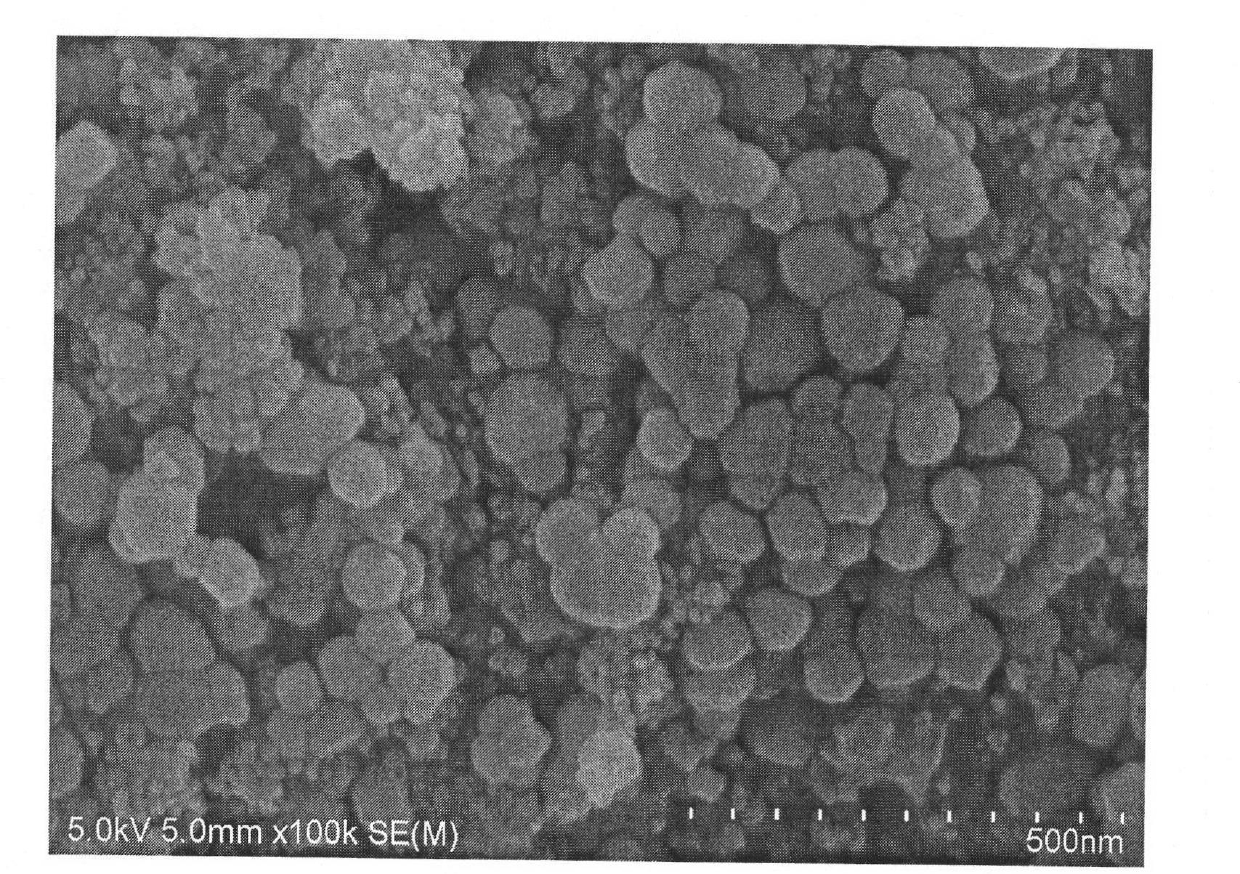

[0069] Embodiment 3: preparation Ce 0.96 Eu 0.04 o 1.93 f 0.1 powder

[0070] Prepare 0.4mol / L cerium acetate solution and 1mol / L ammonium carbonate solution for use. According to the molar ratio of cerium ion: europium ion: fluoride ion being 0.96:0.04:0.1, take the amount of reactant cerium acetate, europium acetate, hydrofluoric acid, mix the taken cerium acetate solution with europium acetate, stir to obtain europium , Cerium metal ion mixed solution. Take 3 times the theoretical amount of precipitant ammonium carbonate, mix the ammonium carbonate solution with hydrofluoric acid evenly, drop the mixed solution of europium and cerium metal ions into it at a constant speed, stir at room temperature for 2 hours, and age for 4 hours after the precipitation is complete to form a slurry After filtering, washing, drying at 80°C for 24h, calcining at 500°C for 10h, and cooling to room temperature, the co-doped nano cerium oxide powder is obtained.

[0071] co-doped F - , Eu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com