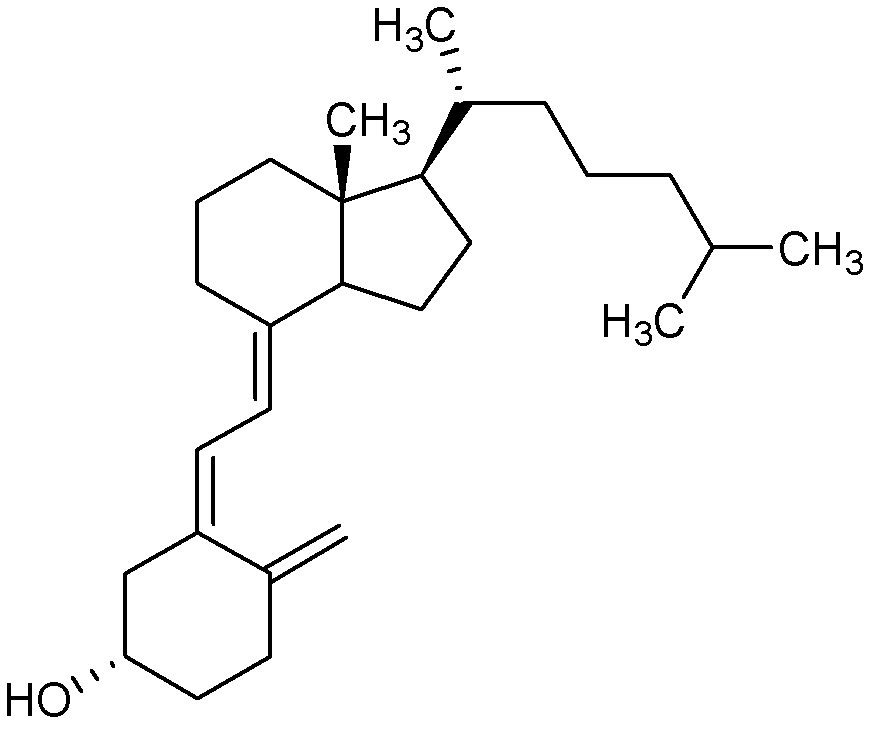

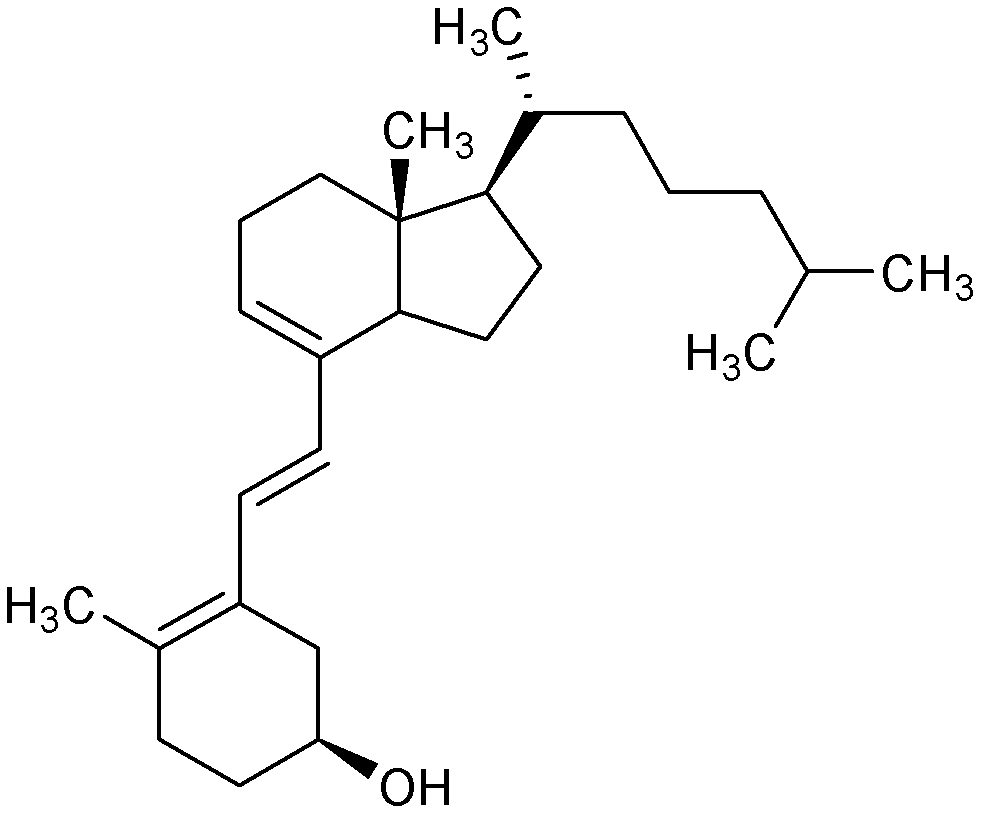

Method for separating vitamin D3 from tachysterol T3

A vitamin and tachysterol technology, applied in the field of chemical engineering, can solve the problems of small processing capacity, low recovery rate, and large solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

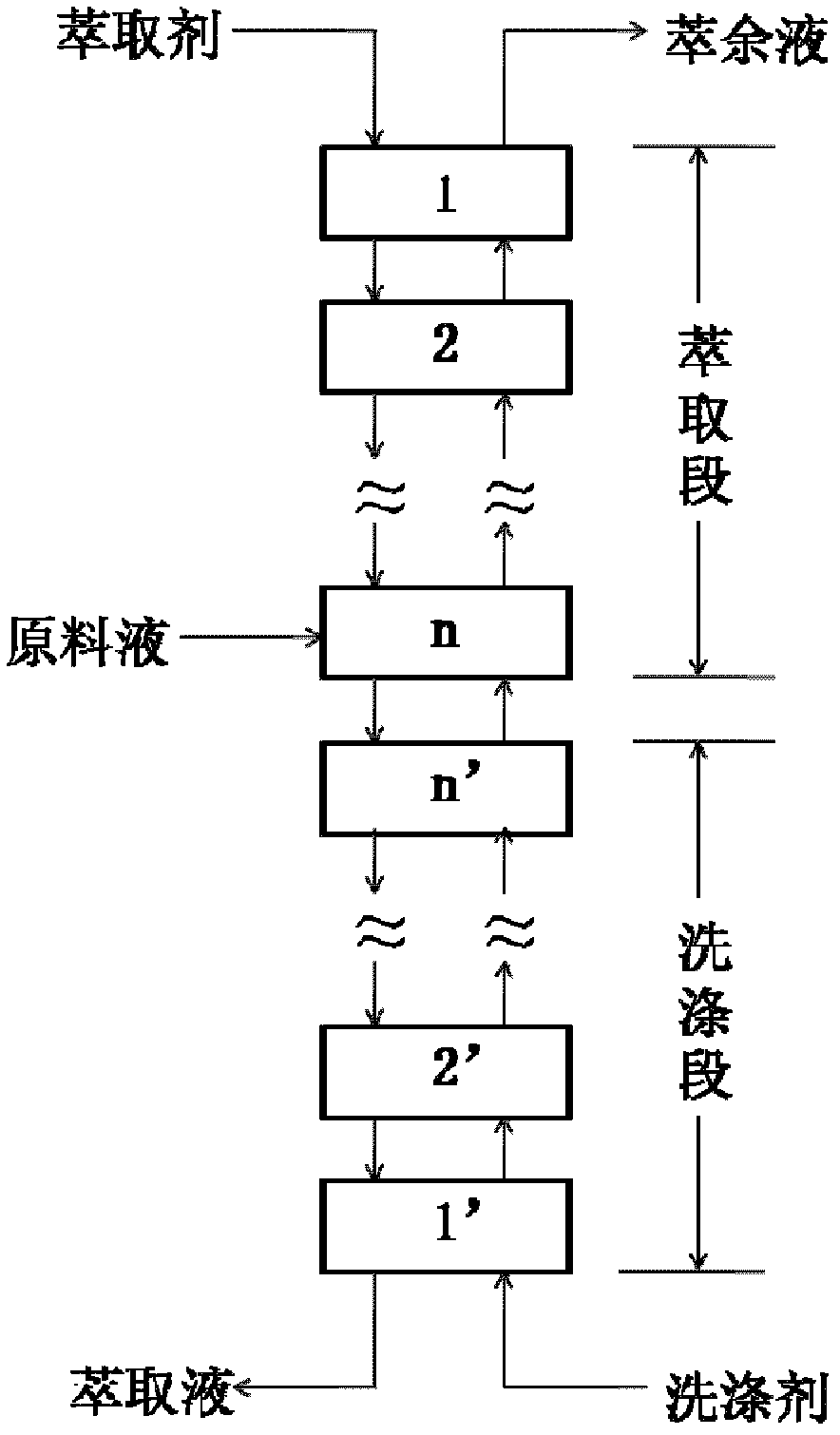

[0040] Dissolve 7-dehydrocholesterol in a mixture of n-hexane, ethanol, and 2,6-di-tert-butyl-p-methoxyphenol, and conduct a photochemical reaction at 20°C for 1 hour. The resulting product is concentrated and subjected to silica gel column chromatography get vitamin d 3 tachysterol T 3 The sum of the mass percentages is 95%, vitamin D 3 tachysterol T 3 The mass ratio of actinic oil pretreatment is 4:1. Synthesis of actinic oil pretreatment with n-hexane to form vitamin D 3 tachysterol T 3 The total concentration is 7.5 grams per liter of raw material liquid, with dimethyl sulfoxide as extractant, with n-hexane as detergent, the flow ratio of extractant, detergent, raw material liquid three is 7.5:5:1,40 at figure 1 Fractional extraction is carried out in the fractionation extraction device shown (there are 10 stages in the extraction section and 10 stages in the washing section). The fractionation extraction is divided into an extraction section and a washing section. ...

Embodiment 2

[0042] Dissolve 7-dehydrocholesterol in a mixture of n-hexane, ethanol, and 2,6-di-tert-butyl-p-methoxyphenol, and conduct a photochemical reaction at 20°C for 1 hour. The resulting product is concentrated and subjected to silica gel column chromatography get vitamin d 3 tachysterol T 3 The sum of the mass percentages is 96%, vitamin D 3 tachysterol T 3 The mass ratio of actinic oil pretreatment is 6:1. Formulating actinic oil pretreatment with n-heptane into vitamin D 3 tachysterol T 3 The total concentration is 80 grams per liter of raw material liquid, with N-methylpyrrolidone as extractant, with n-heptane as detergent, the flow ratio of extractant, detergent, raw material liquid three is 3.6:8:1, -20°C at figure 1 Fractional extraction is carried out in the fractionation extraction device shown (there are 8 stages in the extraction section and 8 stages in the washing section). The fractionation extraction is divided into an extraction section and a washing section. ...

Embodiment 3

[0044]Dissolve 7-dehydrocholesterol in a mixture of n-hexane, ethanol, and 2,6-di-tert-butyl-p-methoxyphenol, and conduct a photochemical reaction at 20°C for 1 hour. The resulting product is concentrated and subjected to silica gel column chromatography get vitamin d 3 tachysterol T 3 The sum of the mass percentages is 94%, vitamin D 3 tachysterol T 3 The mass ratio of actinic oil pretreatment is 5:1. Formulating actinic oil pretreatment with cyclohexane to form vitamin D 3 tachysterol T 3 The total concentration is 0.5 grams per liter of raw material liquid, with 1,2-propanediol as extractant, with cyclohexane as detergent, the flow ratio of extractant, detergent, raw material liquid three is 60:15:1, 30°C at figure 1 Fractional extraction is carried out in the fractionation extraction device shown (there are 10 stages in the extraction section and 10 stages in the washing section). The fractionation extraction is divided into an extraction section and a washing sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com