Method for manufacturing micro-fine spherical titanium powder

A manufacturing method and powder technology, which is applied in the field of fine spherical titanium powder manufacturing, can solve the problems of high oxygen content, high cost, high production efficiency, etc., and achieve the effect of reducing dehydrogenation process, production process reduction and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

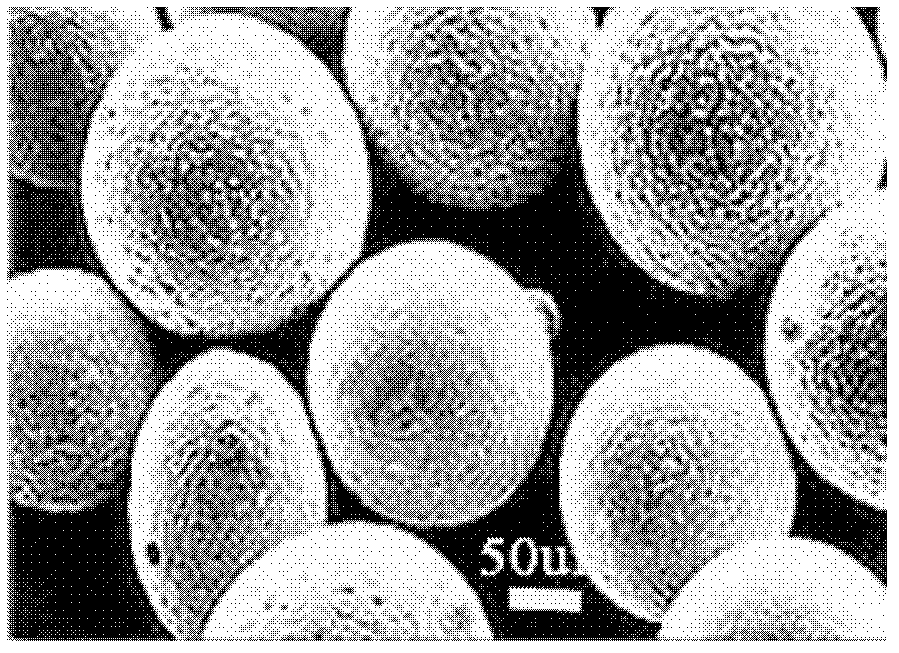

Embodiment 1

[0037]Using sponge titanium as raw material, mix sponge titanium with hydrogen, keep the positive pressure of hydrogen at 0.05MPa, keep warm at 650°C, and crush the hydrogenated sponge titanium with a jet mill. The speed of the jet mill is controlled at 1000r / min, and the particle size is obtained by crushing. Titanium hydride powder less than 45um; titanium hydride powder with an average particle size of 17um is selected, and radio frequency plasma is used for dehydrogenation and spheroidization; the output power of radio frequency plasma is 60kw; both shielding gas and working gas use argon, shielding gas The flow rate is selected at 0.7m 3 / h, the working gas flow rate is selected at 0.4m 3 / h, and then use argon as the carrier gas to transport the titanium hydride powder to the center of the plasma torch, the powder feeding rate is selected at 30g / min, the titanium hydride powder is heated and melted into a spherical shape by the plasma torch during the falling process, an...

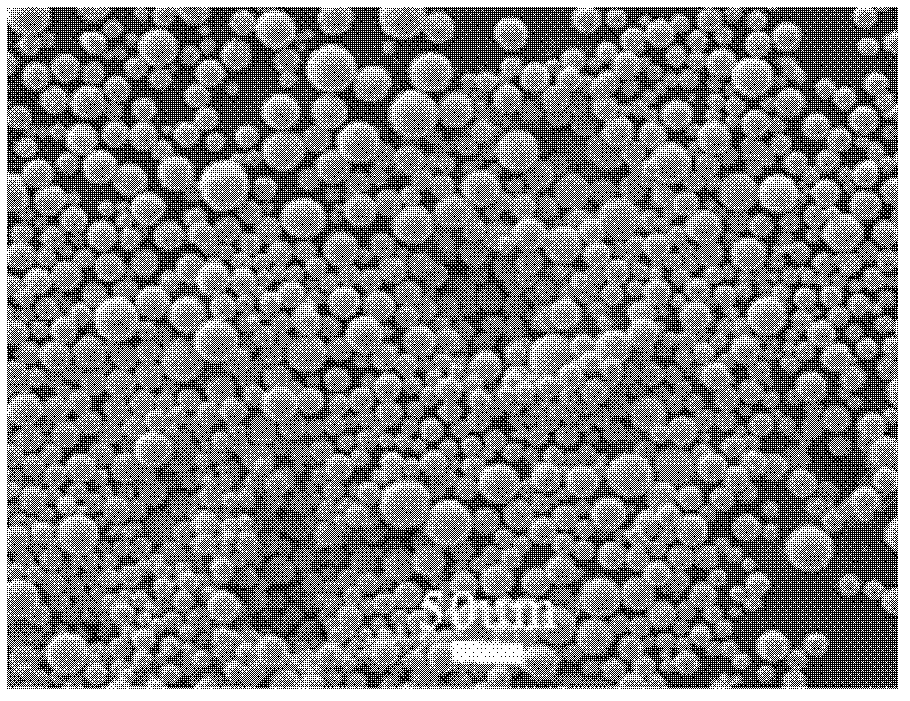

Embodiment 2

[0040] Using sponge titanium as raw material, mix sponge titanium with hydrogen, keep the positive pressure of hydrogen at 0.1MPa, keep warm at 730°C, and crush the hydrogenated sponge titanium with a jet mill. The speed of the jet mill is controlled at 1300r / min, and the particle size is obtained by crushing. Titanium hydride powder less than 45um; titanium hydride powder with an average particle size of 45um is selected, and radio frequency plasma is used for dehydrogenation and spheroidization; the output power of radio frequency plasma is 85kw; both protective gas and working gas use argon, protective gas The flow rate is selected at 1.5m 3 / h, the working gas flow rate is selected at 1.0m 3 / h, and then use argon as the carrier gas to transport the titanium hydride powder to the center of the plasma torch, the powder feeding rate is selected at 300g / min, the titanium hydride powder is heated and melted into a spherical shape by the plasma torch during the falling process,...

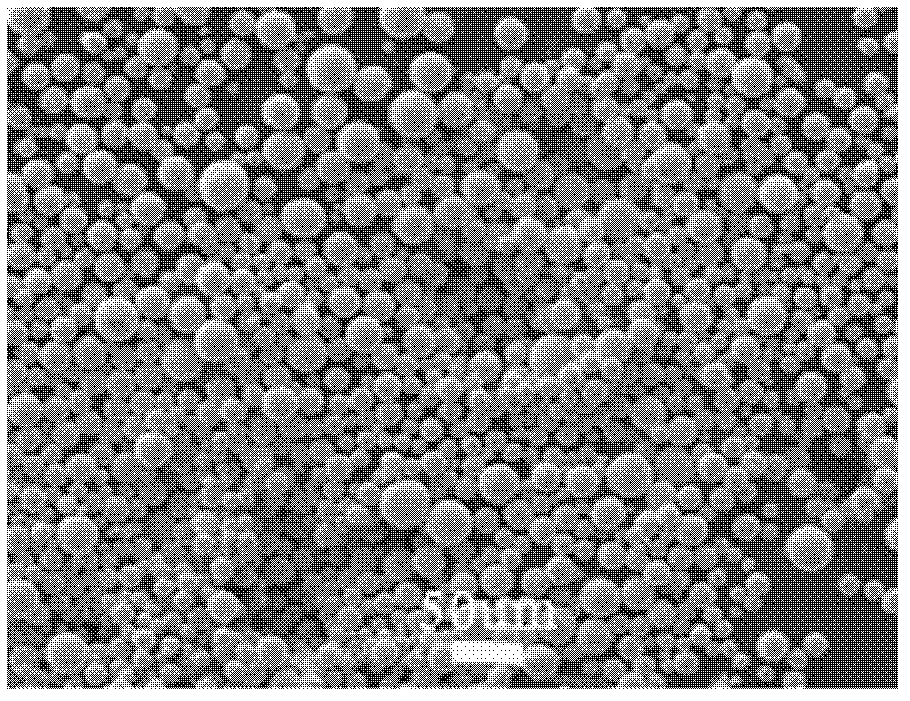

Embodiment 3

[0043] Using sponge titanium as the raw material, mix the sponge titanium with hydrogen, keep the positive pressure of hydrogen at 0.08MPa, keep it warm at 7300°C, and crush the hydrogenated sponge titanium with a jet mill. The speed of the jet mill is controlled at 1150r / min, and the particle size is obtained by crushing. Titanium hydride powder less than 45um; titanium hydride powder with an average particle size of 36um is selected, and radio frequency plasma is used for dehydrogenation and spheroidization; the output power of radio frequency plasma is 70kw; both protective gas and working gas use argon, protective gas The flow rate is selected at 1.0m 3 / h, the working gas flow rate is selected at 10.7m 3 / h, and then use argon as the carrier gas to transport the titanium hydride powder to the center of the plasma torch, the powder feeding rate is selected at 100g / min, the titanium hydride powder is heated and melted into a spherical shape by the plasma torch during the fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com