Method for liquid fermentation cultivation of Pleurotus cornucopiae strain

A liquid fermentation and cultivation method technology, applied in the directions of botanical equipment and methods, horticulture, application, etc., can solve the problems of inability to meet the needs of large-scale cultivation, large amount of cultivated seeds, slow growth rate, etc., and achieve good economic benefits. and social effects, easy inoculation, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

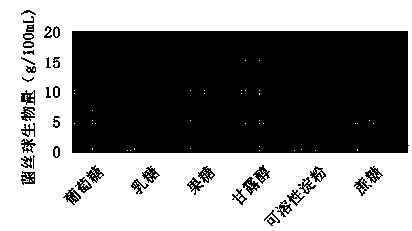

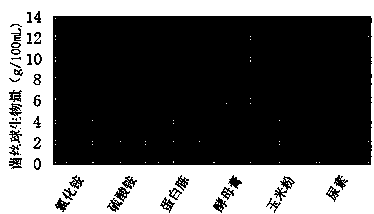

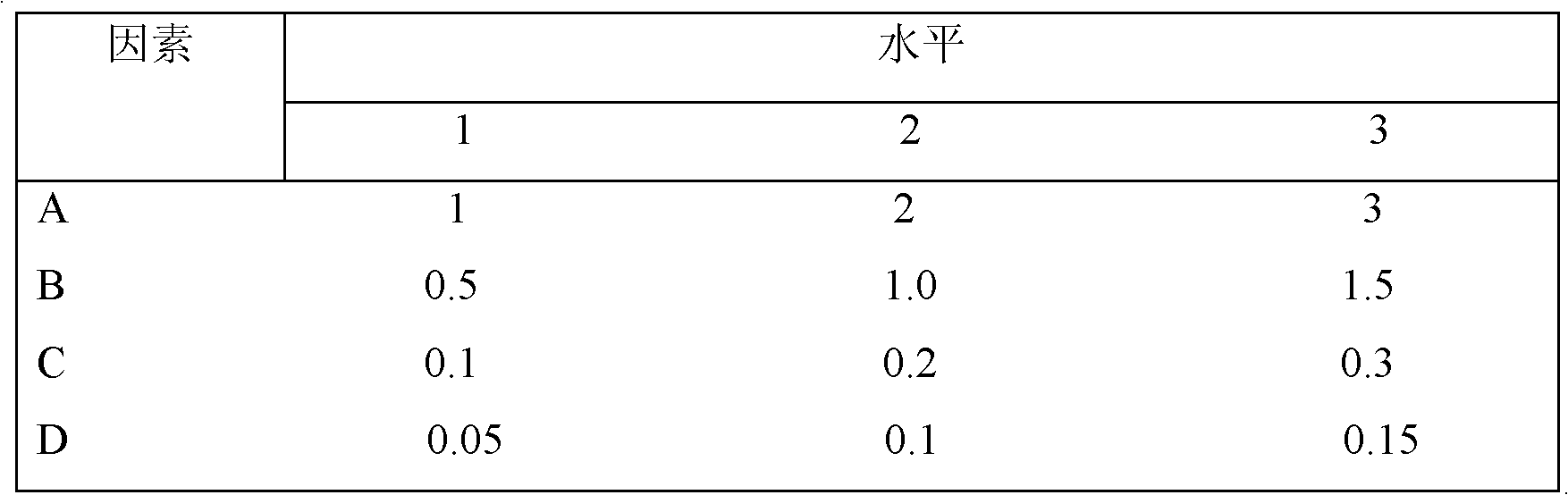

[0027] Take about 0.5cm of activated slant parent species 2 Inoculate the small pieces into the liquid culture medium, shake and cultivate the first-level shake flask strains at 25°C, and then transfer the cultured first-level shake flask liquid strains to the second-level liquid strain shake flasks for each treatment , carried out successively at all levels of culture, unless otherwise specified, all levels of shaking flask culture conditions are: 250mL Erlenmeyer flask liquid volume 100mL, inoculum size 5% (V / V), shaker speed 150r / min, 25 ℃ shaking culture 5 ~7d, similarly, the other levels of liquid strains are also cultivated in the same way. The liquid medium formula of Jiji mushroom liquid strain is: nitrogen source, carbon source, KH 2 PO 4 3g, MgSO 4 ·7H 2 O 1.5g, VB 1 10mg, water 1000mL, pH natural, sterilized at 121°C for 20min. The formula of PDA universal medium for slanted culture of Jiji mushroom: 200g potato, 20g sucrose, 1000mL water, natural pH, steril...

Embodiment 2

[0055] Use 10L full-automatic gas-lift stirring fermenter, liquid capacity is 6L, by 5% (v / v) inoculum size, under 26 ℃ of culture conditions, in liquid culture optimum medium (mannitol 30g, yeast extract 10g, corn Powder 10g, KH 2 PO 4 2g, MgSO 4 ·7H 2 (0.5g, pH value 6.0, water 1000mL), carry out liquid fermentation culture, by sampling analysis and recording fermenter system monitoring data, each growth index variation result of the liquid hyphae of Jiji mushroom in the air-lift fermenter is: In the type fermenter, as the fermentation time prolongs, the parameters of reducing sugar content, dry weight of mycelia, density of mycelium balls and diameter of mycelium balls all have a gradual increase and begin to decline on the 6th day of fermentation. trend; but the pH value is the opposite trend, showing a gradual downward trend. When the fermentation reached the 7th day, the dry weight, density and diameter of the mycelial balls of Jiji mushroom in the fermenter decreas...

Embodiment 3

[0057] After the liquid strain was cultivated in the shake flask, directly inoculate the cultivated species culture material (98% of cottonseed hull, 1% of lime, 1% of gypsum, mass percentage, material to water mass ratio of 1% to 750mL glass strain bottle) : 1.2, the pH value is natural); the solid cultivar basically covers the upper part of the strain bottle. After the solid cultivation material is bagged, it is sterilized at 121°C for 120 minutes, and inoculated when it is cooled to 28°C. The inoculation standard is that the solid strains basically cover the top of the strain bag, and the liquid strains cover the top of the culture material evenly with mycelium balls. After inoculation, the cultivation bags are concentrated in a sterilized cultivation room for constant temperature cultivation at 25°C, and the cultivation is carried out by turning over regularly. Comparing the growth speed of liquid strains and solid cultivars on the cultivation material, the result is: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com