Process for manufacturing gallium nitride-base GaN power integrated circuit

An integrated circuit, gallium nitride-based technology, applied in circuits, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of general electronic circuit system design incompatibility, increase system power consumption and volume, and shorten the drift zone length, reducing the surface electric field, reducing the effect of additional stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The GaN gallium nitride-based process development and boost chip design involved in the present invention will be further described below in conjunction with the accompanying drawings and examples.

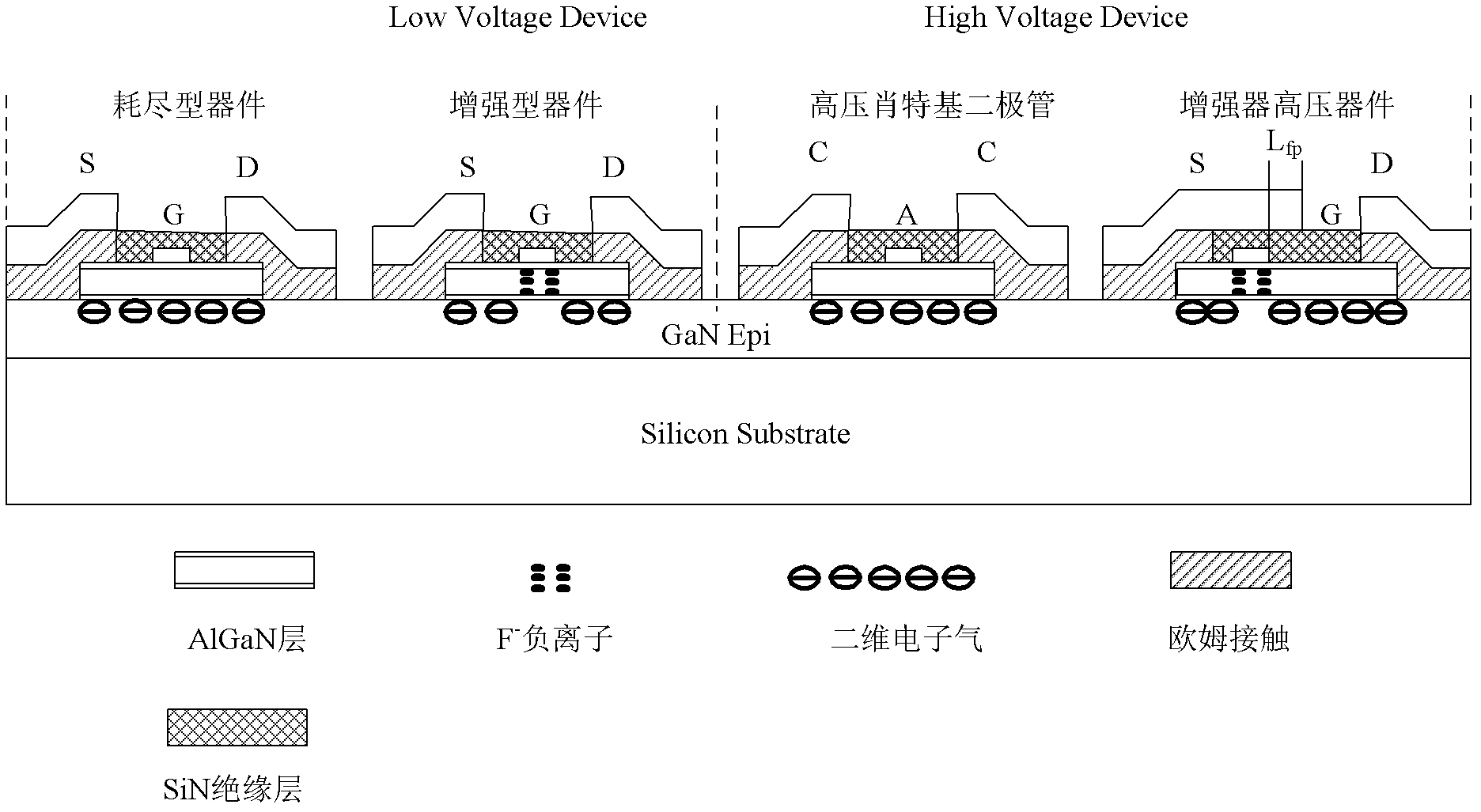

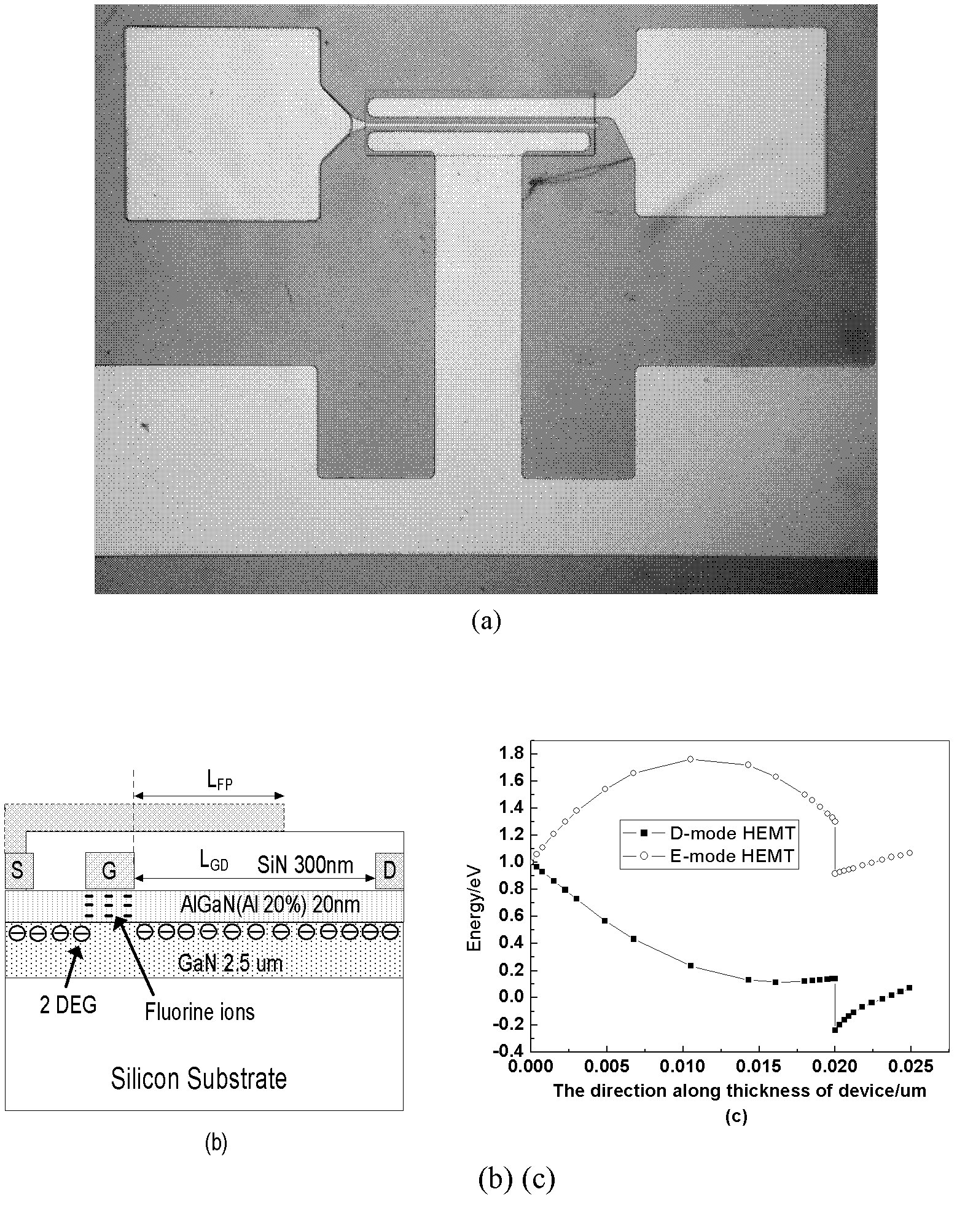

[0040] figure 2 The low-resistance silicon substrate GaN-based process platform for power electronics applications is described. The main devices include enhancement mode / depletion mode HEMTs low-voltage transistors, enhancement mode HEMTs high-voltage devices, and AlGaN / GaN SBD high-voltage Schottky diodes. Enhanced / depleted HEMTs low-voltage devices are mainly used as logic control and self-protection detection functions for chips in HVICs chips. Enhanced HEMTs devices and AlGaN SBD high-voltage Schottky diodes mainly achieve the purpose of power conversion. The high and low voltage areas adopt MESA table isolation technology. The gallium nitride process mainly includes inductively coupled plasma etching equipment STS-RIE etching to form a mesa isolation structure; sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com