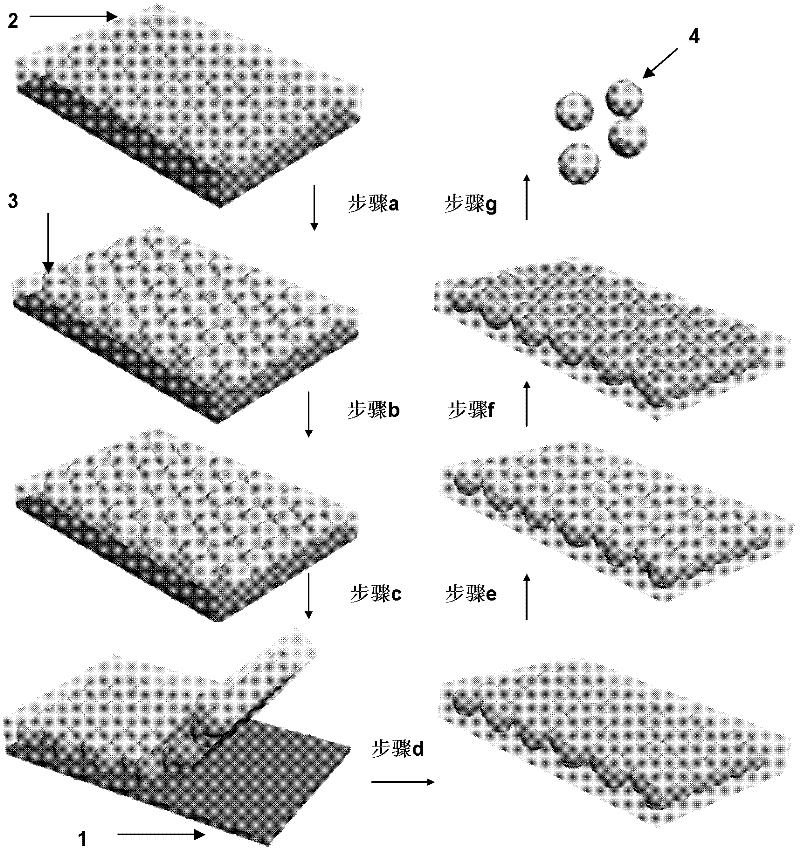

Preparation method for multi-element heterogeneous asymmetric particles

An asymmetric and particle technology, applied in the field of material science, can solve the problems of limited characteristic area, difficult to meet the needs, multiple asymmetric particles or the modified area is not stable enough, etc., to achieve the effect of good stability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Preparation of Hydrophobic Silica Colloidal Microparticles

[0039] At room temperature, 10 mL of an aqueous dispersion of 5 wt % silica colloidal particles (purchased from Fluka) with a diameter of 2 μm was centrifuged to remove water. After that, wash twice with ethanol and disperse in ethanol, and dissolve 100uL octadecyltrichlorosilane in toluene at the same time, then mix the two, stir magnetically for 8 hours, centrifuge and wash the precipitate twice with ethanol, and finally obtain Hydrophobic silica colloidal particles were dispersed in 10 mL of ethanol to obtain 5 wt % hydrophobic silica colloidal particles with a diameter of 2 μm.

Embodiment 2

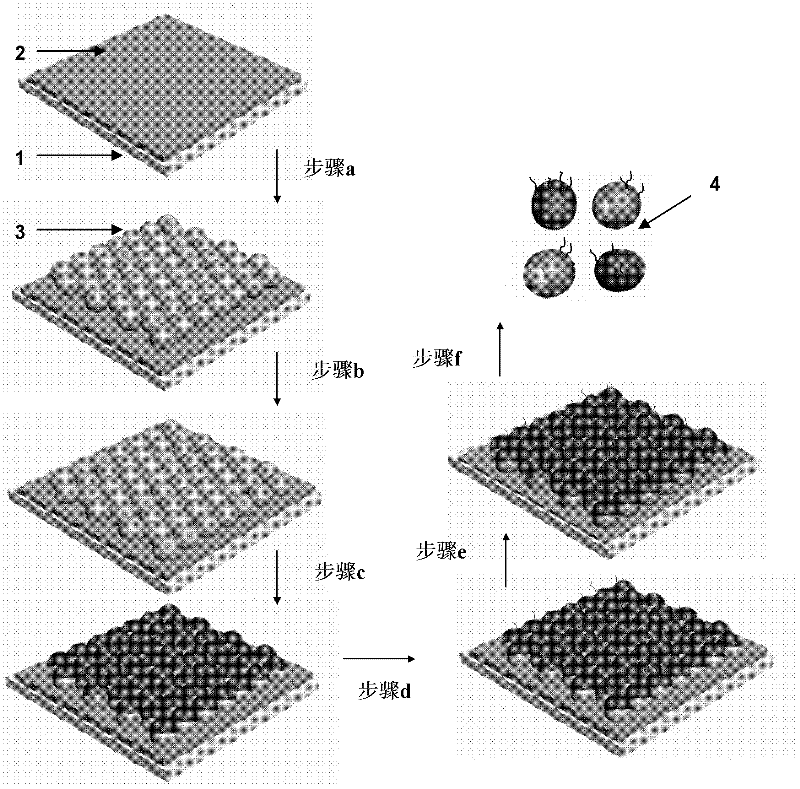

[0040] Example 2: Modification of functional groups on the surface of silica colloidal particles

[0041] Use a disposable syringe to draw 0.2mL of hydrophobic silica colloid particles with a diameter of 2um prepared in Example 1, and slowly add them dropwise to a watch glass filled with water at a uniform speed. Adding 50 μL of 10 wt% sodium dodecylsulfonate aqueous solution, the colloidal silica particles will form a monolayer of hexagonal close arrangement. Put the clean silicon wafer treated with an oxidant with a volume ratio of concentrated sulfuric acid and hydrogen peroxide of 7:3 into the liquid surface, lift it up at an inclination of 45°C, and finally place the lifted silicon wafer on a 30° slope. After natural drying, a two-dimensional ordered silicon dioxide monolayer particle array is obtained.

[0042] 200 μL of polystyrene toluene solution with a concentration of 30 mg / mL was dropped onto the silicon wafer covered with a single layer of silica colloidal microp...

Embodiment 3

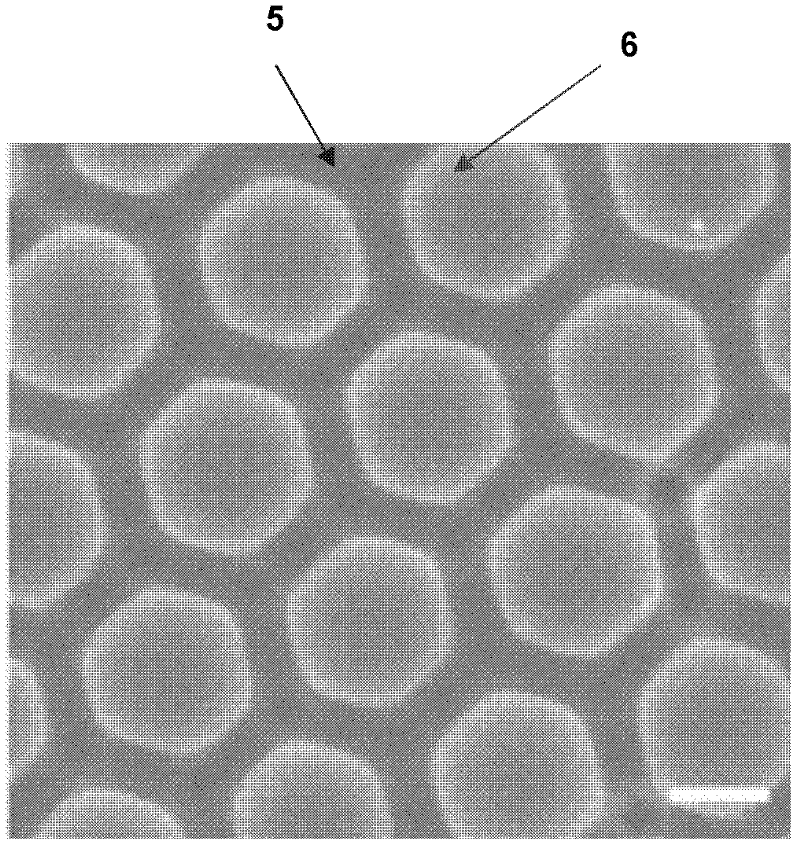

[0044] Example 3: Fluorescent modification of specific regions on the surface of silica colloidal particles

[0045] Dilute 15mL to a concentration of 10 -3 The mercaptopropionic acid of mol / L is the CdTe (the particle diameter of CdTe is 4.0nm) solution of ligand with Na 2 HPO 4 and NaH 2 PO 4 The buffer solution is adjusted to a pH value of 7.4, and then 0.002g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 0.002g of N-hydroxysuccinimide are added. After stirring and fully dissolving, the silicon wafer with the silica colloidal microparticle array modified by the surface amino functionalization obtained in the above steps was added into the reactor, and the reaction was carried out under magnetic stirring at room temperature for 5 hours. After the reaction, the silicon wafer was rinsed with a large amount of water, blown dry with nitrogen, and then drip-coated 100mg / mL PS toluene solution on its surface. After drying, the polymer film containing the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com