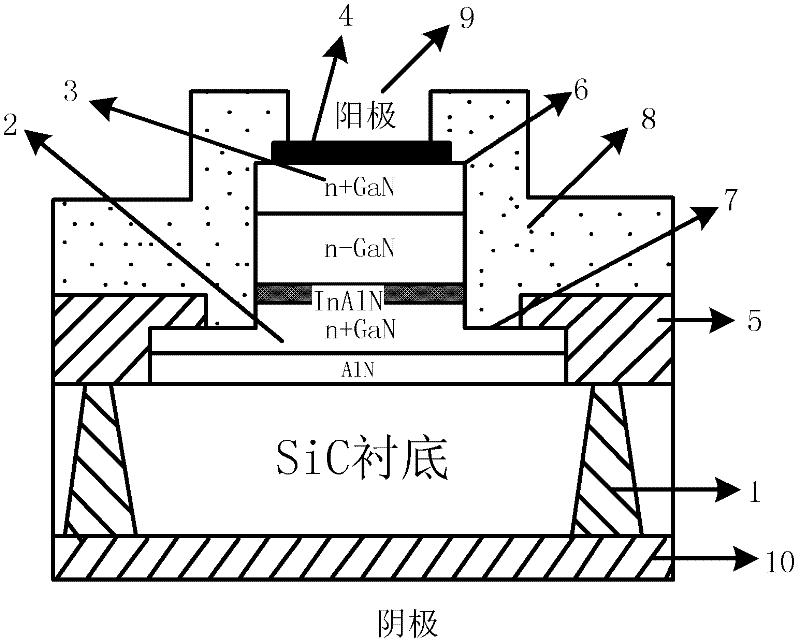

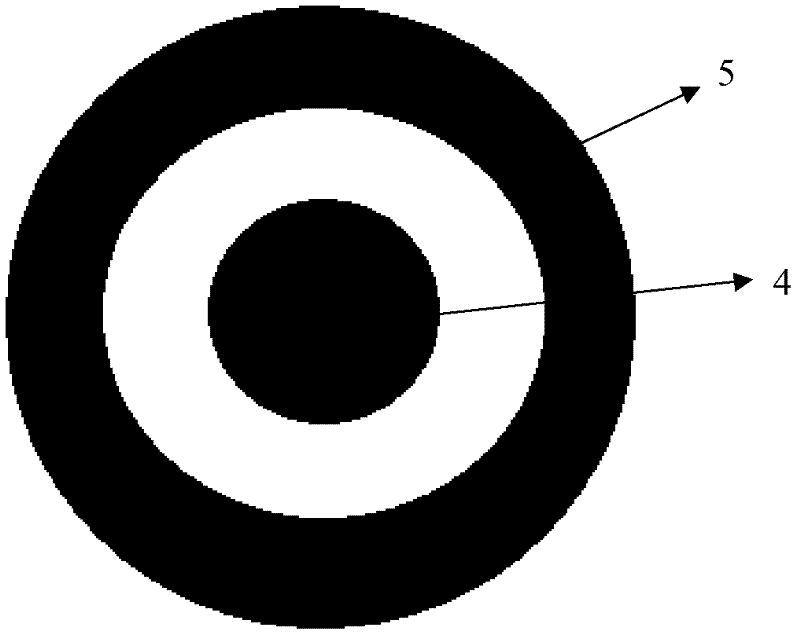

Terahertz GaN Gunn diode based on SiC substrate and manufacturing method thereof

A Gunn diode, terahertz technology, applied in the field of microelectronics, can solve the problem of high dislocation density at the interface of the heterojunction, and achieve the elimination of piezoelectric polarization effect, high power and frequency, and improve the characteristics of high frequency and high power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

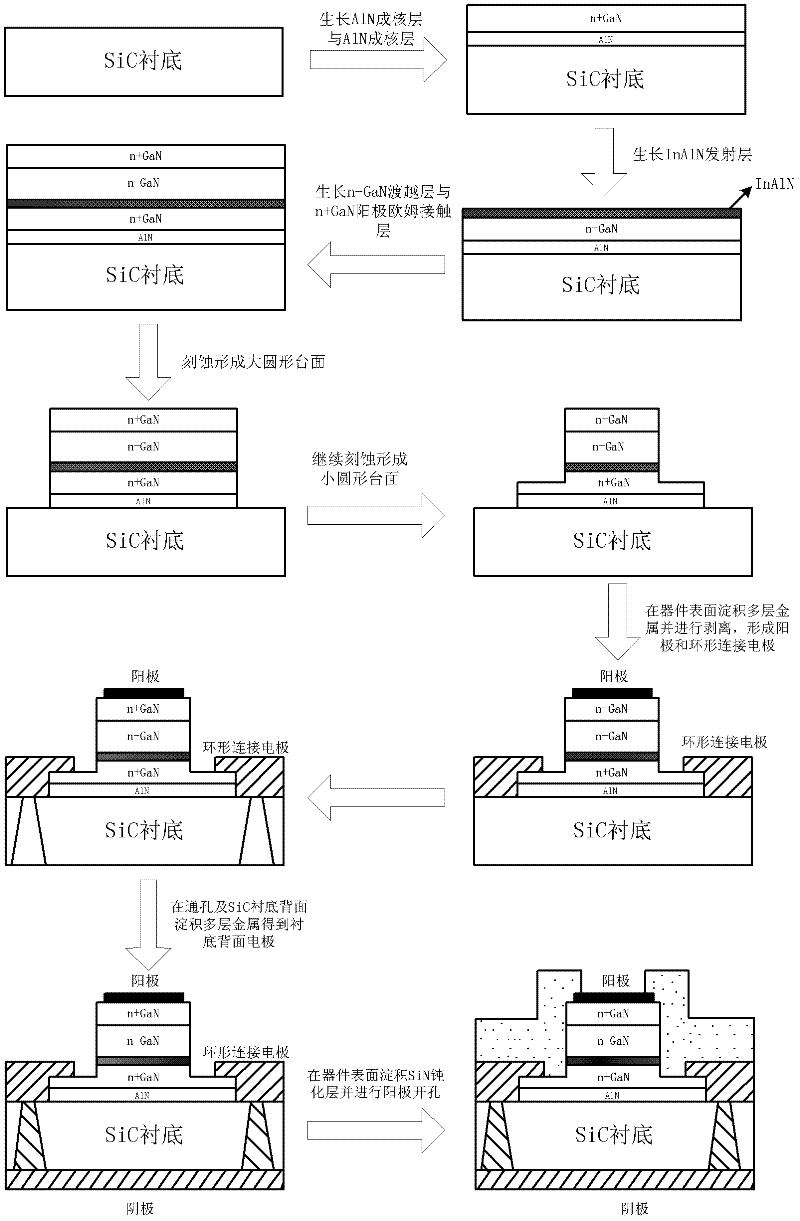

[0037] The steps of making the terahertz GaN Gunn diode in the present invention are as follows:

[0038] Step 1: Select a 4H-SiC semi-insulating SiC substrate with a diameter of 2 inches, and thin the back surface to a substrate thickness of 150 μm.

[0039] Step 2: Using trimethylaluminum and high-purity nitrogen as aluminum and nitrogen sources on MOCVD, a low-temperature AlN nucleation layer with a thickness of 30 nm is first grown on the SiC substrate, and the growth conditions are as follows: the temperature is 600 ° C, The pressure was 40 Torr.

[0040] Step 3, continue to adopt the MOCVD process, use triethylgallium and high-purity nitrogen gas as the gallium source and nitrogen source respectively, and silane gas as the n-type doping source, and epitaxially grow a layer with a doping concentration of 1.0× on the AlN nucleation layer 10 18 cm -3 , n with a thickness of 0.5 μm + The GaN cathode ohmic contact layer is grown under the following conditions: a temperatu...

Embodiment 2

[0051] The steps of making the terahertz GaN Gunn diode in the present invention are as follows:

[0052] Step 1, select a 6H-SiC conduction-type n-type SiC substrate with a diameter of 3 inches, and a doping concentration of 2.0×10 18 cm -3 , the back side is thinned to a substrate thickness of 200 μm.

[0053] Step 2: Using trimethylaluminum and high-purity nitrogen as aluminum and nitrogen sources, a low-temperature AlN nucleation layer with a thickness of 50nm is grown on the SiC substrate by using a MOCVD process with a temperature of 600°C and a pressure of 40 Torr.

[0054] Step 3, continue to use the MOCVD process, under the process conditions of a temperature of 1000 ° C and a pressure of 40 torr, triethylgallium and high-purity nitrogen gas are used as the gallium source and nitrogen source respectively, and silane gas is used as the n-type doping source. An epitaxial growth layer on the AlN nucleation layer with a doping concentration of 2.0×10 18 cm -3 , n with...

Embodiment 3

[0076] The steps of making the terahertz GaN Gunn diode in the present invention are as follows:

[0077] In step A, a 4H-SiC semi-insulating SiC substrate with a diameter of 3 inches is selected, and the back surface is thinned to a substrate thickness of 150 μm.

[0078] Step B, make n + GaN cathode ohmic contact layer:

[0079] B1) First, using trimethylaluminum and high-purity nitrogen as the aluminum source and nitrogen source respectively, a low-temperature AlN nucleation layer with a thickness of 40 nm is grown on the SiC substrate by MOCVD process, and the growth conditions are as follows: the temperature is 600 ° C, The pressure is 40 torr;

[0080] B2) Under the process conditions of a temperature of 1000°C and a pressure of 40 Torr, continue to use the MOCVD process, using triethylgallium and high-purity nitrogen as the gallium source and nitrogen source respectively, and silane gas as the n-type doping source. On the nucleation layer, epitaxially grow a layer wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com