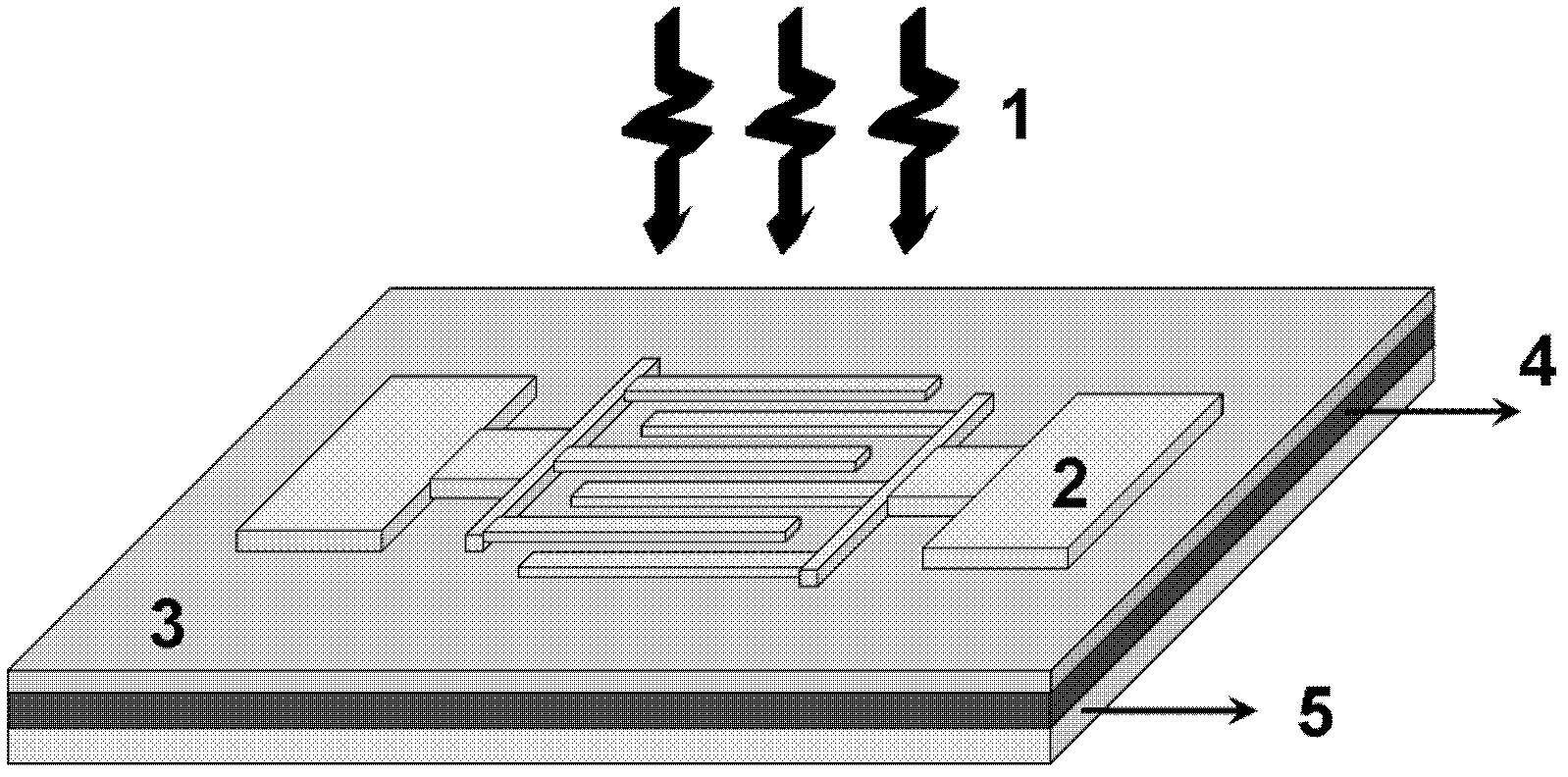

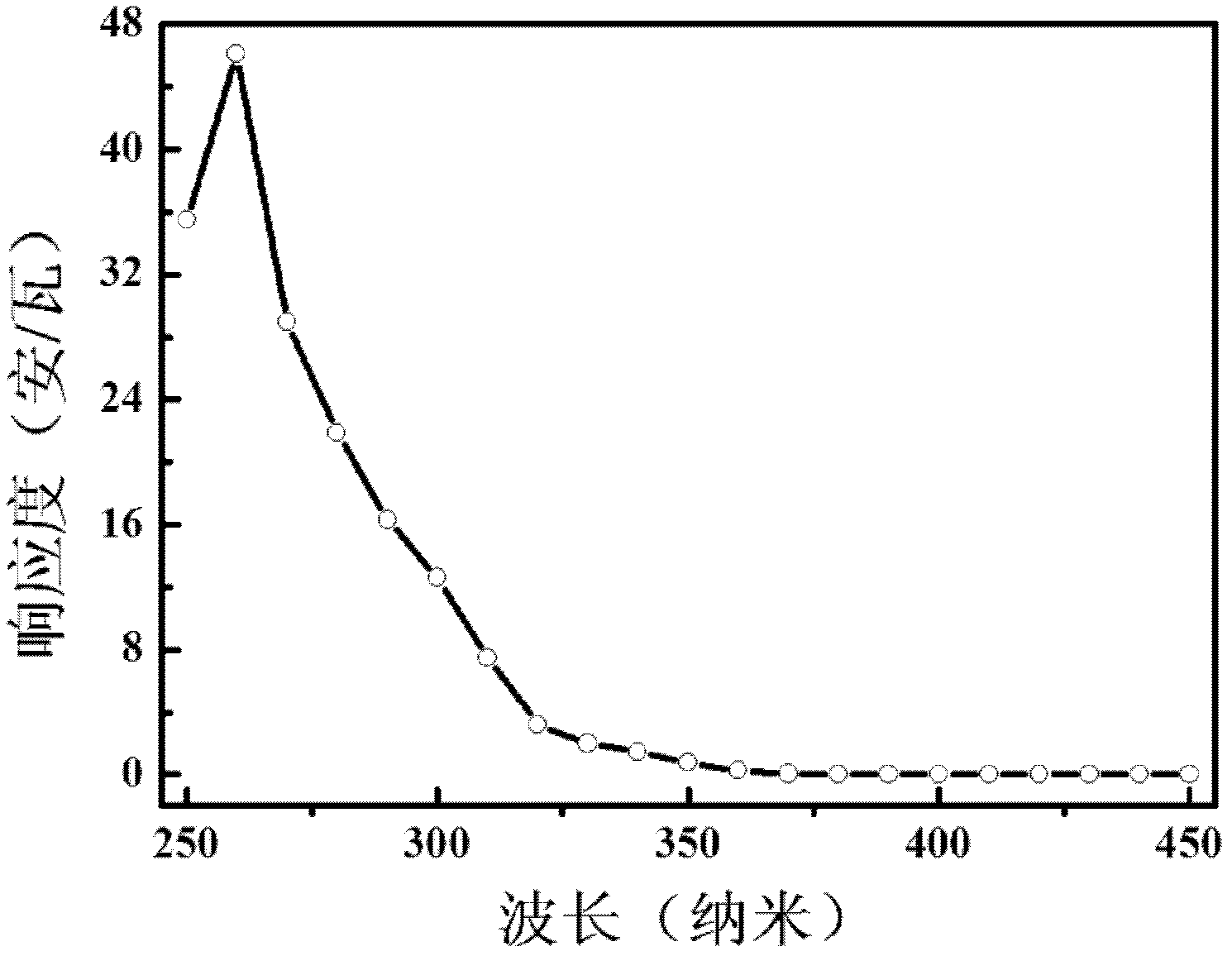

Ultraviolet detector based on titanium dioxide/strontium titanate heterojunction and preparation method

A technology of heterojunction and ultraviolet light, which is applied in the direction of semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of low responsivity of ultraviolet detectors, and achieve the goal of being suitable for mass production, easy integration, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of TiO by Sol-Gel Technology 2 thin film, add 10mL tetrabutyl titanate to 100mL absolute ethanol at room temperature, then add 10mL glacial acetic acid dropwise as a catalyst, after 60 minutes of stirring, a uniform and transparent light yellow solution is obtained; slowly add 10mL acetylacetone to inhibit Hydrolysis, the color of the solution becomes darker, continue to stir for 1 hour; finally, slowly add 10mL of deionized water to the above solution dropwise at a rate of 1mL / min, continue to stir for 2 hours, and obtain a uniform and transparent light yellow sol, which is left to age 6 hours.

[0036] Preparation of SrTiO by Sol-Gel Technology 3 Nano-film, dissolve 0.25g strontium acetate in 5mL acetic acid at room temperature, stir evenly, add dropwise 0.4mL tetrabutyl titanate, stir for 30 minutes to obtain a white uniform solution, and finally add 10mL ethanol as a solvent to the above solution, Stirring was continued for 1 hour to obtain a uniform a...

Embodiment 2

[0042] Preparation of TiO by Sol-Gel Technology 2 thin film, add 10mL tetrabutyl titanate to 100mL absolute ethanol at room temperature, then add 10mL glacial acetic acid dropwise as a catalyst, after 60 minutes of stirring, a uniform and transparent light yellow solution is obtained; slowly add 10mL acetylacetone to inhibit Hydrolysis, the color of the solution becomes darker, continue to stir for 1 hour; finally, slowly add 10mL of deionized water to the above solution dropwise at a rate of 1mL / min, continue to stir for 2 hours, and obtain a uniform and transparent light yellow sol, which is left to age 6 hours.

[0043] Preparation of SrTiO by Sol-Gel Technology 3 Nano-film, dissolve 0.25g strontium acetate in 5mL acetic acid at room temperature, stir evenly, add dropwise 0.4mL tetrabutyl titanate, stir for 30 minutes to obtain a white uniform solution, and finally add 10mL ethanol as a solvent to the above solution, Stirring was continued for 1 hour to obtain a uniform a...

Embodiment 3

[0049] Preparation of TiO by Sol-Gel Technology 2 thin film, add 10mL tetrabutyl titanate to 100mL absolute ethanol at room temperature, then add 10mL glacial acetic acid dropwise as a catalyst, after 60 minutes of stirring, a uniform and transparent light yellow solution is obtained; slowly add 10mL acetylacetone to inhibit Hydrolysis, the color of the solution becomes darker, continue to stir for 1 hour; finally, slowly add 10mL of deionized water to the above solution dropwise at a rate of 1mL / min, continue to stir for 2 hours, and obtain a uniform and transparent light yellow sol, which is left to age 6 hours.

[0050] Preparation of SrTiO by Sol-Gel Technology 3 Nano-film, dissolve 0.25g strontium acetate in 5mL acetic acid at room temperature, stir evenly, add dropwise 0.4mL tetrabutyl titanate, stir for 30 minutes to obtain a white uniform solution, and finally add 10mL ethanol as a solvent to the above solution, Stirring was continued for 1 hour to obtain a uniform a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com