High-dielectric-constant polymer-potassium salt composite film material and preparation method thereof

A high dielectric constant, polymer technology, applied in metal material coating process, ion implantation plating, coating, etc., to achieve the effect of miniaturization and integration, simple equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

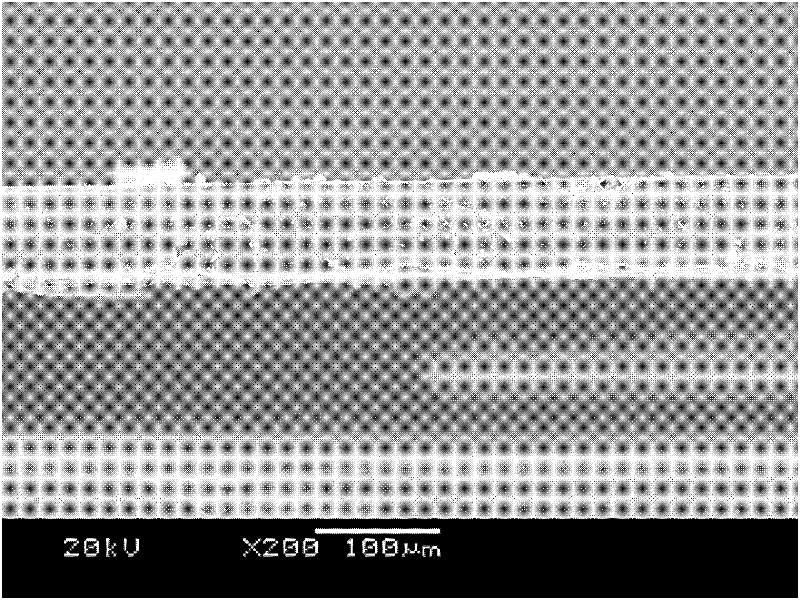

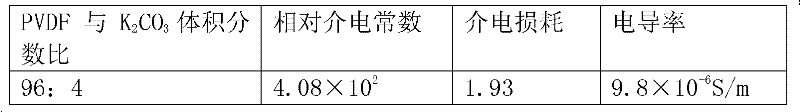

[0034] Potassium salt used is potassium carbonate (K 2 CO 3 ), the polymer polyvinylidene fluoride (PVDF) and K 2 CO 3 Calculate the amount of raw materials according to the ratio of volume fraction 96:4, and weigh the raw materials with an electronic balance; then put them into a ball mill jar, use absolute ethanol as a medium, and ball mill on a conventional ball mill for 6 hours, and the mixed powder after ball milling The material is dried in a constant temperature drying oven; then add 15ml of organic solvent N,N-dimethylformamide (DMF) to obtain a mixed liquid, and the mixed liquid is heated to 60°C on a magnetic stirrer, and the PVDF is fully dissolved by stirring; Ultrasonic cleaner ultrasonically oscillates to K 2 CO 3 Evenly disperse in the dissolved liquid to obtain a composite liquid; slowly pour the composite liquid on a flat glass sheet cleaned with deionized water and absolute ethanol to make it evenly cast, and then put it in a constant temperature drying o...

Embodiment 2

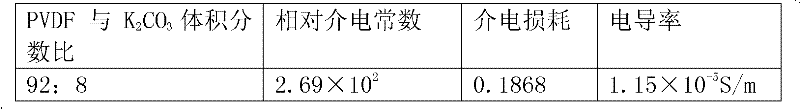

[0038] Potassium salt used is potassium carbonate (K 2 CO 3 ), the polymer polyvinylidene fluoride (PVDF) and K 2 CO 3Calculate the amount of raw materials according to the ratio of volume fraction 92:8, and weigh the raw materials with an electronic balance; then put them into a ball mill jar, use absolute ethanol as a medium, and ball mill on a conventional ball mill for 8 hours, and the mixed powder after ball milling The material is dried in a constant temperature drying oven; then add 20ml of organic solvent N,N-dimethylformamide (DMF) to obtain a mixed liquid, and the mixed liquid is heated to 80°C on a magnetic stirrer, and the PVDF is fully dissolved by stirring; Ultrasonic cleaner ultrasonically oscillates to K 2 CO 3 Disperse evenly in the dissolved liquid to obtain a composite liquid; slowly pour the composite liquid on a flat glass sheet cleaned with deionized water and absolute ethanol to make it evenly cast, and then put it in a constant temperature drying ov...

Embodiment 3

[0042] Potassium salt used is potassium carbonate (K 2 CO 3 ), the polymer polyvinylidene fluoride (PVDF) and K 2 CO 3 Calculate the amount of raw materials according to the ratio of volume fraction 89:11, weigh the raw materials with an electronic balance; then put them into a ball mill jar, use absolute ethanol as the medium, and ball mill on a conventional ball mill for 10 hours, and the mixed powder after ball milling The material is dried in a constant temperature drying oven; then add 25ml of organic solvent N,N-dimethylformamide (DMF) to obtain a mixed liquid, and the mixed liquid is heated to 80°C on a magnetic stirrer, and stirred to fully dissolve the PVDF; Ultrasonic cleaner ultrasonically oscillates to K 2 CO 3 Uniformly disperse in the dissolved liquid to obtain a composite liquid; slowly pour the composite liquid on a flat glass sheet cleaned with deionized water and absolute ethanol to make it flow uniformly, put it in a constant temperature drying oven, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com