Piston rod and production method thereof as well as carbonitriding agent for piston rod surface treatment

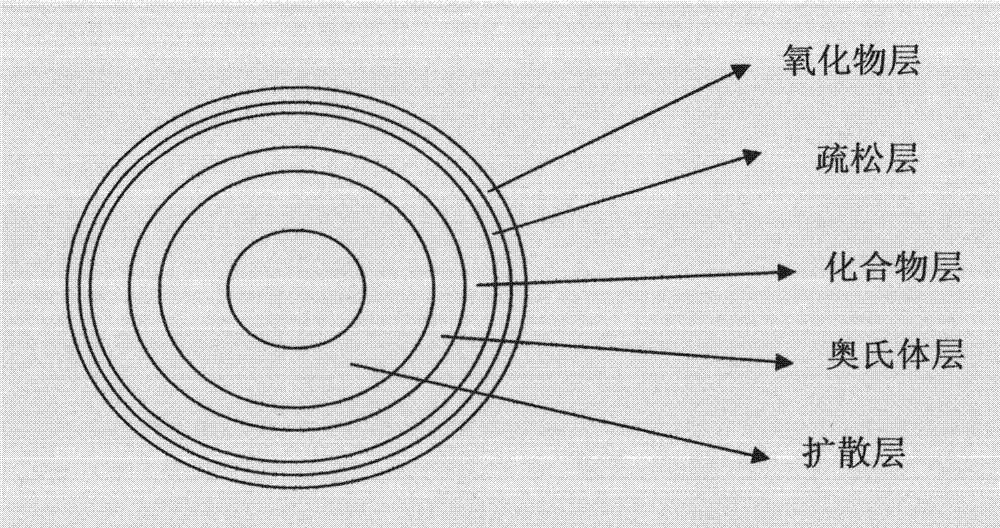

A carbonitriding and surface treatment technology, used in piston rods, engine components, mechanical equipment, etc., can solve the problem of hindering the absorption process of active nitrogen atoms and carbon atoms, poor wear resistance and corrosion resistance, and the addition of loose layers of piston rods. Thickness and other problems, to achieve the effect of shortening the production cycle, smoothing the surface, and optimizing the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0062] A carbonitriding agent for piston rod surface treatment, the composition is as follows:

[0063] Urea: 20%, Thiourea: 13%, Barium Acetate: 12%, Calcium Carbonate: 24%, Barium Carbonate: 22%, Lithium Carbonate: 9%;

[0064] A kind of production method of the piston rod that uses this carbonitriding agent to carry out surface treatment, comprises the steps:

[0065] (1) Preliminary processing of piston rod

[0066] A. Cutting: Cut off the piston rod according to the predetermined length;

[0067] B. Annealing: eliminate the stress of the piston rod;

[0068] C. Straightening: meet the straightness requirements of the piston rod;

[0069] D. Coarse grinding: remove impurities such as rust on the surface of the piston rod;

[0070] E. High-frequency quenching: increase the surface hardness of the piston rod;

[0071] F. Tempering straightening: meet the straightness requirements of the piston rod;

[0072] G. Grinding: Make the outer diameter of the piston rod reach t...

Embodiment 1

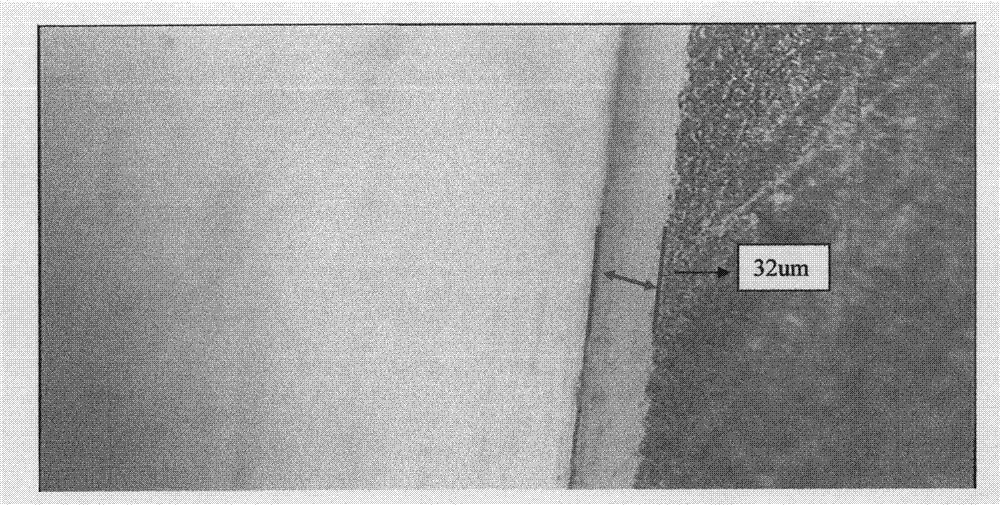

[0080] Embodiment 1 metallographic picture sees figure 2 , the magnification is 200 (times), and the product performance index is:

[0081] 1) Thickness of piston rod seepage layer: oxide layer thickness: 4μm, loose layer thickness: 3μm, compound layer thickness: 32μm, austenite layer thickness: 9μm, diffusion layer thickness: 260μm;

[0082] 2) Corrosion resistance of the piston rod: according to the GB / T10125-1997 standard, the neutral salt spray test will not rust for 285 hours;

[0083] 3) Surface roughness of the piston rod: 0.06μm, 0.07μm, 0.08μm, 0.07μm, 0.06μm;

[0084] 4) The surface Vickers hardness of the piston rod: 654, 635, 643, 642, 650, the unit is kg / mm 2 .

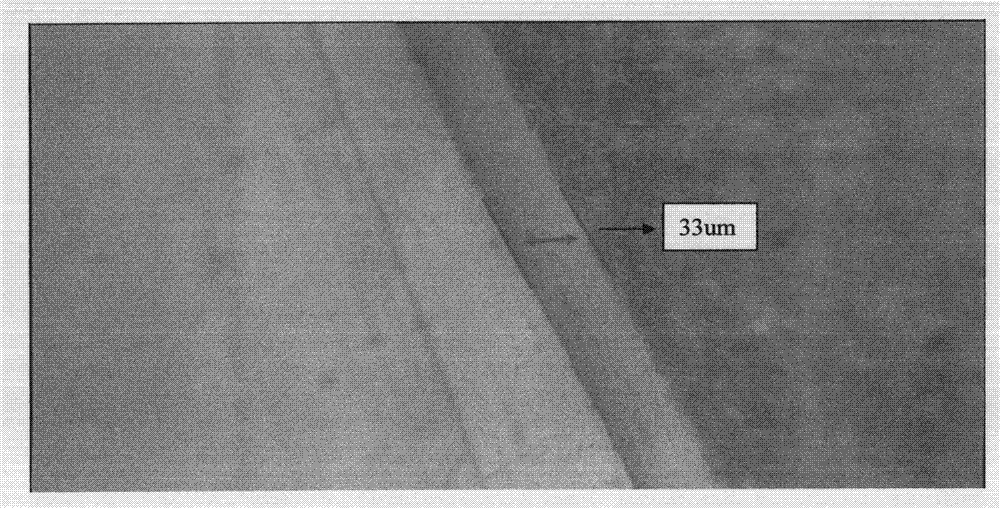

specific Embodiment 2

[0085] A carbonitriding agent for piston rod surface treatment, the composition is as follows:

[0086] Urea: 22%, Thiourea: 14%, Barium Acetate: 12%, Calcium Carbonate: 25%, Barium Carbonate: 23%, Lithium Carbonate: 4%;

[0087] A kind of production method of the piston rod that uses this carbonitriding agent to carry out surface treatment, comprises the steps:

[0088] (1) Preliminary processing of piston rod

[0089] A. Cutting: Cut off the piston rod according to the predetermined length;

[0090] B. Annealing: eliminate the stress of the piston rod;

[0091] C. Straightening: meet the straightness requirements of the piston rod;

[0092] D. Coarse grinding: remove impurities such as rust on the surface of the piston rod;

[0093] E. High-frequency quenching: increase the surface hardness of the piston rod;

[0094] F. Tempering straightening: meet the straightness requirements of the piston rod;

[0095] G. Grinding: Make the outer diameter of the piston rod reach t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com