Method for preparing lithium vanadium phosphate and lithium manganese phosphate composite anode material through rheological phase reaction

A composite cathode material, lithium manganese phosphate technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of difficult insertion and extraction of lithium ions, low ion diffusion rate, low ion conductivity, etc., to achieve uniform size distribution, Improved electrochemical performance and uniform particle size distribution

Inactive Publication Date: 2012-05-09

GUILIN UNIVERSITY OF TECHNOLOGY

View PDF2 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But LiMnPO 4 The ion diffusion rate in the material is small, and its own ionic conductivity is low, making it difficult for lithium ions to intercalate and extract normally in the material, so LiMnPO with electrochemical activity 4 Materials are difficult to synthesize

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0018] Table 1: Experimental conditions and results of Example 1

[0019]

[0020] Example 2:

Embodiment 2

[0022] Table 2: Experimental conditions and results of Example 2

[0023]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

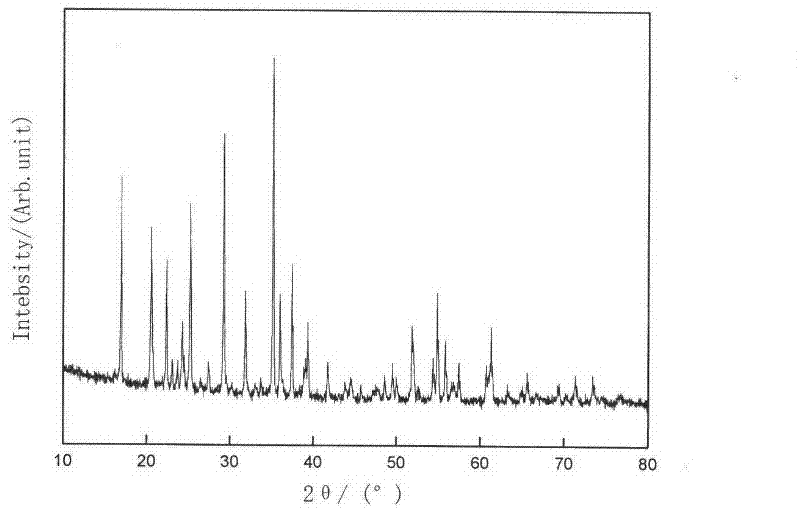

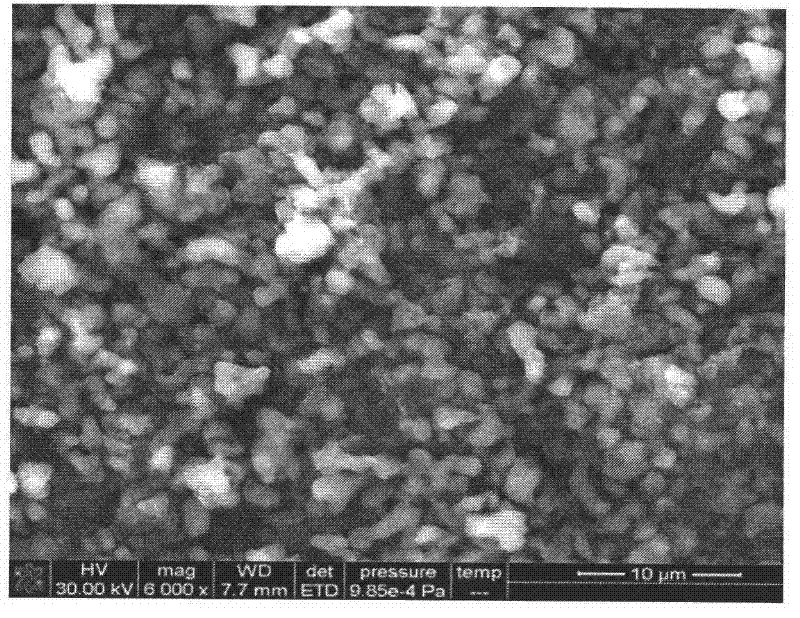

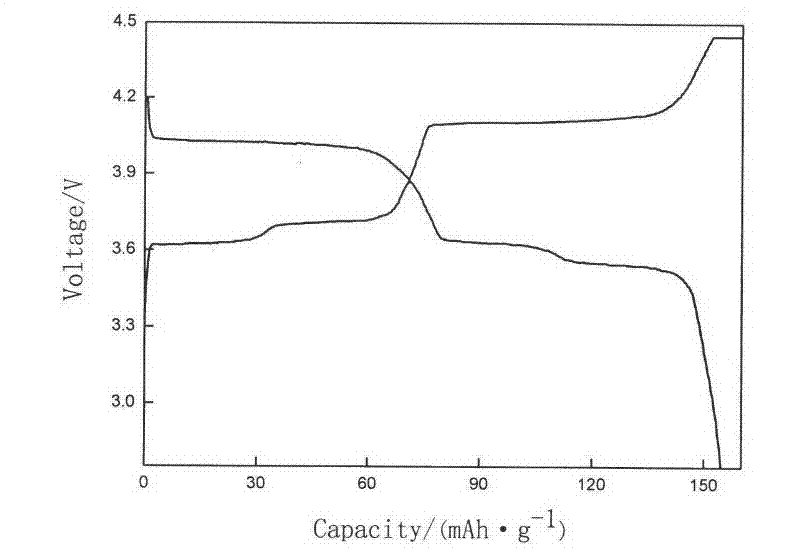

The invention discloses a method for preparing a lithium vanadium phosphate and lithium manganese phosphate composite anode material through rheological phase reaction, which comprises the following steps: uniformly mixing ammonium metavanadate, manganese salt, phosphate salt, polyethylene glycol and lithium salt dissolved into water, reacting for 5-10 hours in constant-temperature water bath of 75-95 DEG C to form a rheological jelly and calcining the dried rheological jelly for 10-20 hours in the non-oxidizing atmosphere of 650-800 DEG C, namely Li3V2 (PO4)3.LiMnPO4. The invention has the beneficial effects that the method is simple and convenient, is easy to control and low in cost; the synthesized Li3V2 (PO4)3.LiMnPO4 composite material overcomes the defect of low electronic conductivity of a monomer material Li3V2 (PO4)3 and low ion diffusion rate, low ion conductivity and difficulty in synthesis of a monomer material LiMnPO4; and compared with the monomer materials, the charge and discharge performance and the cycling performance of a sample are respectively improved.

Description

technical field [0001] The invention relates to a method for preparing lithium vanadium phosphate and manganese lithium phosphate composite materials by rheological phase reaction. Background technique [0002] Due to its high performance and high stability, lithium-ion batteries play a pivotal role and status in the fields of electronic information, new energy, electric vehicles (EV) and hybrid electric vehicles (HEV), and environmental protection. Therefore, exploring lithium-ion batteries with excellent performance Battery cathode materials have broad and deep meanings. A.K.Padhi et al. believe that Li with NASCION structure 3 V 2 (PO 4 ) 3 It is one of the positive electrode materials for lithium-ion batteries with great development potential. Li 3 V 2 (PO 4 ) 3 It has the advantages of stable structure, high working potential (3.6-4.5V, vs. Li / Li+), high theoretical specific capacity (197mAh / g) and good reversibility of rapid charge and discharge. However, the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/58

CPCY02E60/12Y02E60/10

Inventor 钟胜奎李伟姜吉琼徐悦斌王友

Owner GUILIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com