Gradient functional inert anode material used for zinc electrodeposition and its preparation method

A gradient function, inert anode technology, applied in the scientific field, can solve the problems of size limitation, high brittleness, low current efficiency, etc., to achieve the effect of reducing cell voltage and power consumption, improving anti-deformation ability, and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

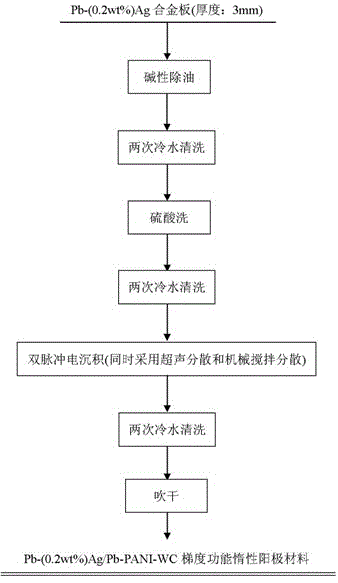

[0025] Embodiment 1: as figure 1 Shown, the specific preparation steps of this Pb-(0.2wt%)Ag / Pb-PANI-WC gradient function inert anode material are:

[0026] (1) Immerse the common electrolytic lead plate (anode material) into the 2+ In the electrolyte, it is connected with the anode wire of the double pulse power supply;

[0027] (2) The Pb-Ag alloy plate (the Ag content is 0.2wt%, the thickness of the plate is 3mm, and the cathode substrate) is first degreased by alkaline, then washed twice with cold water, then pickled, and then washed with cold water Wash twice, immerse it into the 2+ In the electrolyte, it is connected with the cathode wire of the double pulse power supply; alkaline degreasing is chemical alkaline degreasing, and the composition of the degreasing liquid used is: sodium hydroxide: 10g / L, sodium carbonate: 20g / L , Trisodium phosphate: 50g / L, sodium silicate: 10g / L, the process conditions are: oil removal temperature: 80 ℃, oil removal time: 4min. The aci...

Embodiment 2

[0030] Example 2 :like figure 1 Shown, the specific preparation steps of this Pb-(0.2wt%)Ag / Pb-PANI-WC gradient function inert anode material are:

[0031] (1) Immerse the common electrolytic lead plate (anode material) into the 2+ In the electrolyte, it is connected with the anode wire of the double pulse power supply;

[0032] (2) The Pb-Ag alloy plate (the Ag content is 0.2wt%, the thickness of the plate is 3mm, and the cathode substrate) is first degreased by alkaline, then washed twice with cold water, then pickled, and then washed with cold water After cleaning twice, immerse it into the 2+ In the electrolyte, it is connected with the cathode wire of the double pulse power supply; alkaline degreasing is chemical alkaline degreasing, and the composition of the degreasing liquid used is: sodium hydroxide: 12g / L, sodium carbonate: 25g / L , Trisodium phosphate: 60g / L, sodium silicate: 12g / L, the process conditions are: oil removal temperature: 85 ℃, oil removal time: 6mi...

Embodiment 3

[0035] Example 3 :like figure 1 Shown, the specific preparation steps of this Pb-(0.2wt%)Ag / Pb-PANI-WC gradient function inert anode material are:

[0036] (1) Immerse the electrolytic lead plate (anode material) into the 2+ In the electrolyte, it is connected with the anode wire of the double pulse power supply;

[0037] (2) The Pb-Ag alloy plate (the Ag content is 0.2wt%, the thickness of the plate is 3mm, and the cathode substrate) is first degreased by alkaline, then washed twice with cold water, then pickled, and then washed with cold water After cleaning twice, immerse it into the 2+ In the electrolyte, it is connected with the cathode wire of the double pulse power supply; alkaline degreasing is chemical alkaline degreasing, and the composition of the degreasing liquid used is: sodium hydroxide: 15g / L, sodium carbonate: 30g / L , Trisodium phosphate: 70g / L, sodium silicate: 15g / L, the process conditions are: oil removal temperature: 90 ℃, oil removal time: 8min. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com