Acrylate modified maleopimaric acid aqueous polyurethane emulsion and preparation method thereof

A technology of maleopimaric acid and water-based polyurethane, which is applied in the field of preparation of acrylate-modified maleopimaric acid water-based polyurethane emulsion, can solve the problems of low hardness and poor water resistance, and achieve good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A kind of preparation method of acrylate modified maleopimaric acid aqueous polyurethane emulsion, the steps are:

[0033] The first step is to prepare the maleopimaric acid polyester polyol: compound the modified rosin polyacid alone or with the dibasic acid with 3 to 6 carbon atoms in any ratio, and mix it with the small molecule polyol, at 150-270°C Make maleopimaric acid polyester polyol through dehydration condensation reaction under the condition;

[0034] The second step is to prepare maleopimaric acid water-based polyurethane emulsion: the maleopimaric acid polyester polyol obtained in the first step is compounded alone or with polyether polyol or polyester polyol in any ratio, at 100-120°C Vacuum dehydration for 2-3 hours, after cooling, add diisocyanate and catalyst to react at 60-90°C for 1-3 hours, then add hydrophilic monomer and react at 60-90°C for 1-2 hours, then add organic solvent and small molecule diffuser The chain agent is reacted at 0-70°C for 3-...

Embodiment 1

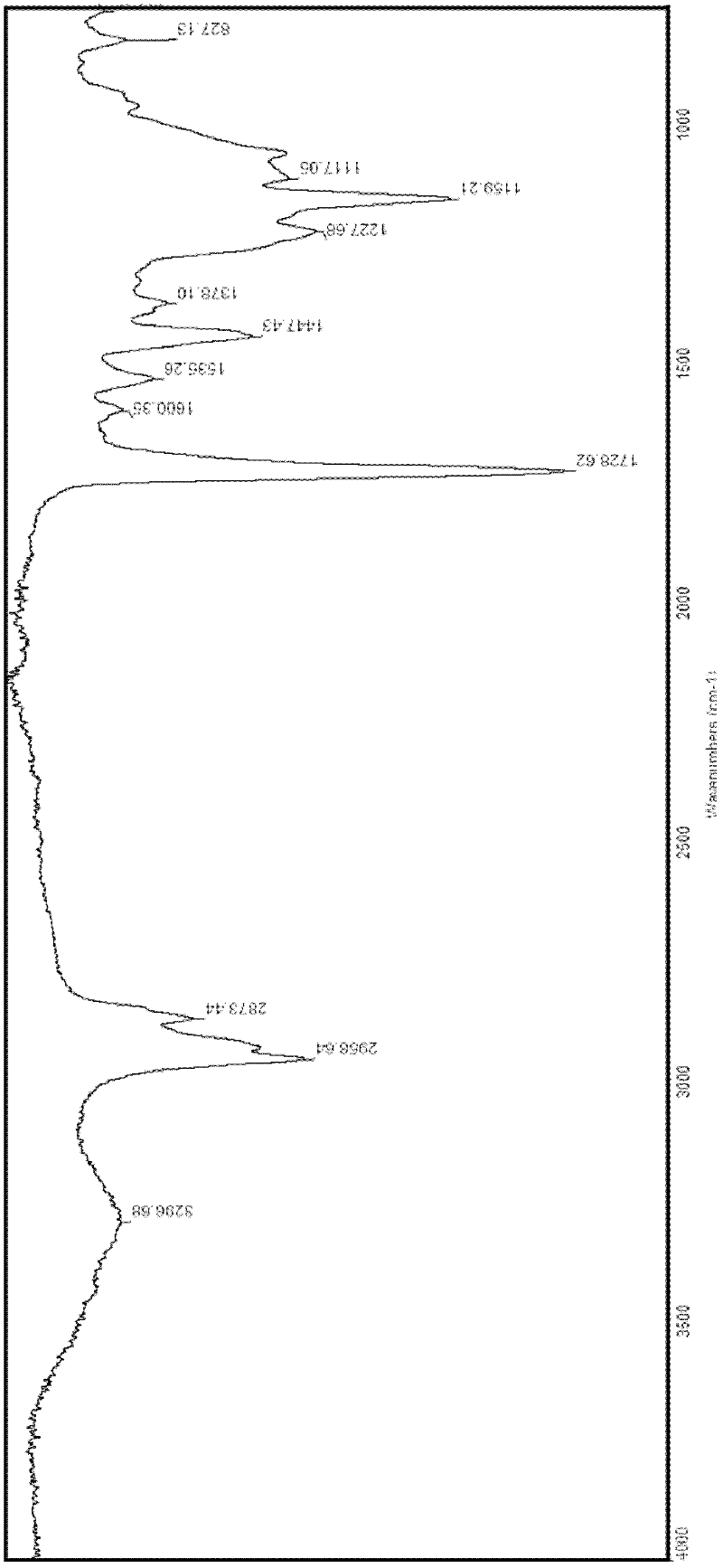

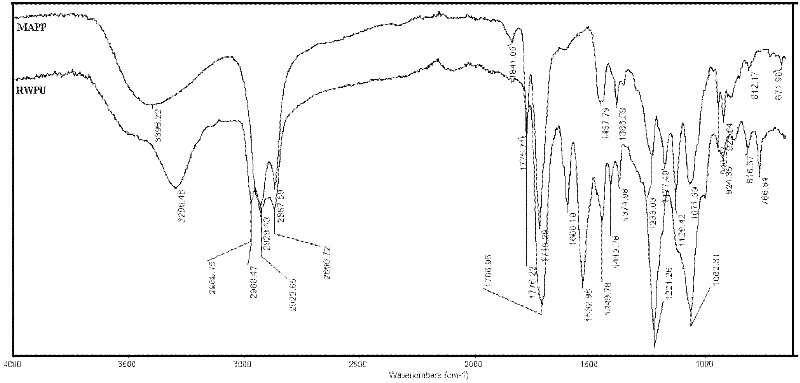

[0045] Add 15.6g of maleopimaric acid and 11.8g of diethylene glycol to a 500ml flask equipped with a thermometer, a stirrer, an air duct, and a distillation head, react at 220°C until the acid value of the system drops to 100mg / g, and then react under vacuum When the acid value of the system drops below 60mg / g, the temperature is lowered to 160°C and the material is discharged to obtain maleopimaric acid polyester polyol (MAPP) with a hydroxyl value of 68.2mg / g.

[0046] Take the above maleopimaric acid polyester polyol MAPP 8.8g, polyether N-210 16.3g, vacuum dehydration at 120°C for 2-3h, add toluene diisocyanate (TDI) 13.5g after cooling, react at 78°C for 2h, then Add 2.16g of dimethylolpropionic acid (DMPA) and react at 75°C for 1h, then add acetone, diethylene glycol (DEG) 2.5g, and catalyst dibutyltin dilaurate (DBT) 0.02g and react at 60°C for 4-5h , cooled to 15°C, added triethylamine (TEA) for neutralization, dispersed in water under vigorous stirring, and finally v...

Embodiment 2

[0057] Add 15.0 g of maleopimaric acid and 11.9 g of diethylene glycol to a 250 ml flask equipped with a thermometer, a stirrer, an air duct, and a distillation head, and react at 220 ° C until the acid value of the system drops to 100 mg / g, and then react under vacuum conditions When the acid value of the system drops below 60mg / g, the temperature is lowered to 160°C and the material is discharged to obtain maleopimaric acid polyester polyol (MAPP) with a hydroxyl value of 85.7mg / g.

[0058] Take 5g of maleopimaric acid polyester polyol and 20g of polyether N-210, vacuum dehydrate at 100-120°C for 2-3 hours, add TDI 16g after cooling, react at 85°C for 1.5 hours, then add 2.3g of DMPA , react at 85°C for 1 hour, finally add 4.3g DEG and 12g acetone, react at 60°C for 4-5 hours, add TEA to neutralize after cooling, stir vigorously, disperse in 100g water under high-speed shear, and remove acetone under reduced pressure to obtain Maleopimaric acid aqueous polyurethane emulsion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com