Polyaniline/titanium dioxide/clay nanometer composite photocatalyst and preparation method thereof

A titanium dioxide and nano-composite technology, applied in the direction of organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the difficulties of catalyst separation and recovery, small particle size of nano-titanium dioxide, Reduce the number of hydroxyl radicals, etc., to save the acid addition step, save acid consumption, and realize the effect of regeneration and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

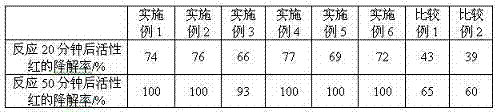

Examples

Embodiment 1

[0021] Example 1: 200 g of deionized water was added to 20 g of attapulgite, ultrasonically dispersed for 0.5 hour with a JYD650 intelligent ultrasonic cell pulverizer, and a slurry with a mass ratio of water to attapulgite of 10:1 was prepared.

[0022] At 20°C, add the prepared attapulgite slurry to 60 ml with a molar concentration of 2 mol L -1 In the titanium tetrachloride aqueous solution, stir evenly, acidify for 0.5 hours, heat the system to 95° C., and keep it warm for 4 hours to obtain a titanium dioxide / attapulgite nanocomposite slurry.

[0023] Cool the titanium dioxide / attapulgite nanocomposite slurry to 15 °C, add 2 g of aniline, and use a molar concentration of 1 mol L -1 Aqueous sodium hydroxide solution to adjust the pH value of the system to 1, stir and mix evenly, and then add 21.5 milliliters of it dropwise with a dropper to the mixed system with a molar concentration of 1mol L -1 Ammonium persulfate aqueous solution, the dripping time of the ammonium persu...

Embodiment 2

[0026] Example 2: Add 4000 grams of deionized water to 200 grams of attapulgite, and disperse at high speed (7000 rpm) for 3 hours with a ME100 type high-shear mixing emulsifier, and prepare a mass ratio of water to attapulgite of 20 :1 slurry.

[0027] At 60°C, add the prepared attapulgite slurry to 625 ml with a molar concentration of 4mol L -1 In the aqueous solution of titanium tetrachloride, stir evenly, acidify for 2 hours, heat the system to 80° C., and keep it warm for 10 hours to obtain a titanium dioxide / attapulgite nanocomposite slurry.

[0028] Cool the titanium dioxide / attapulgite nanocomposite slurry to 0 °C, add 30 g of aniline, and use a molar concentration of 3 mol L -1 The pH value of the ammonia solution to adjust the system is 4. After stirring and mixing evenly, add 1610.5 milliliters of the solution dropwise with a dropper to the mixing system and the molar concentration is 0.4mol L -1 Ammonium persulfate aqueous solution, the dropwise addition time of ...

Embodiment 3

[0031] Embodiment 3: Add 1000 grams of deionized water to 200 grams of attapulgite, disperse for 1 hour with a small-scale high-pressure homogenizer (Shanghai Donghua High Pressure Homogenizer Factory), and prepare a mass ratio of water to attapulgite of 5 : 1 slurry, at 0°C, the prepared attapulgite slurry was added to 1000 milliliters with a molar concentration of 0.5mol L -1In the aqueous solution of titanium tetrachloride, stir evenly, acidify for 4 hours, heat the system to 120° C., and keep it warm for 1 hour to obtain a titanium dioxide / attapulgite nanocomposite slurry.

[0032] Cool the titanium dioxide / attapulgite nanocomposite slurry to 30 °C, add 4 g of aniline, and use a molar concentration of 2 mol L -1 Potassium hydroxide aqueous solution to adjust the pH value of the system to 3, after stirring and mixing evenly, add 13.45 milliliters of 1.6 mol L dropwise to the mixing system with a dropper -1 Ammonium persulfate aqueous solution, the dropwise addition time of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com