Grapheme/chitosan/cuprous oxide composite material and preparation method and applications thereof

A cuprous oxide, composite material technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, water/sludge/sewage treatment, etc., can solve the problem of incomplete degradation of pollutants, high performance Cost, secondary pollution and other issues, to achieve good biocompatibility and adsorption catalytic performance, improve biocompatibility, and promote the effect of synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

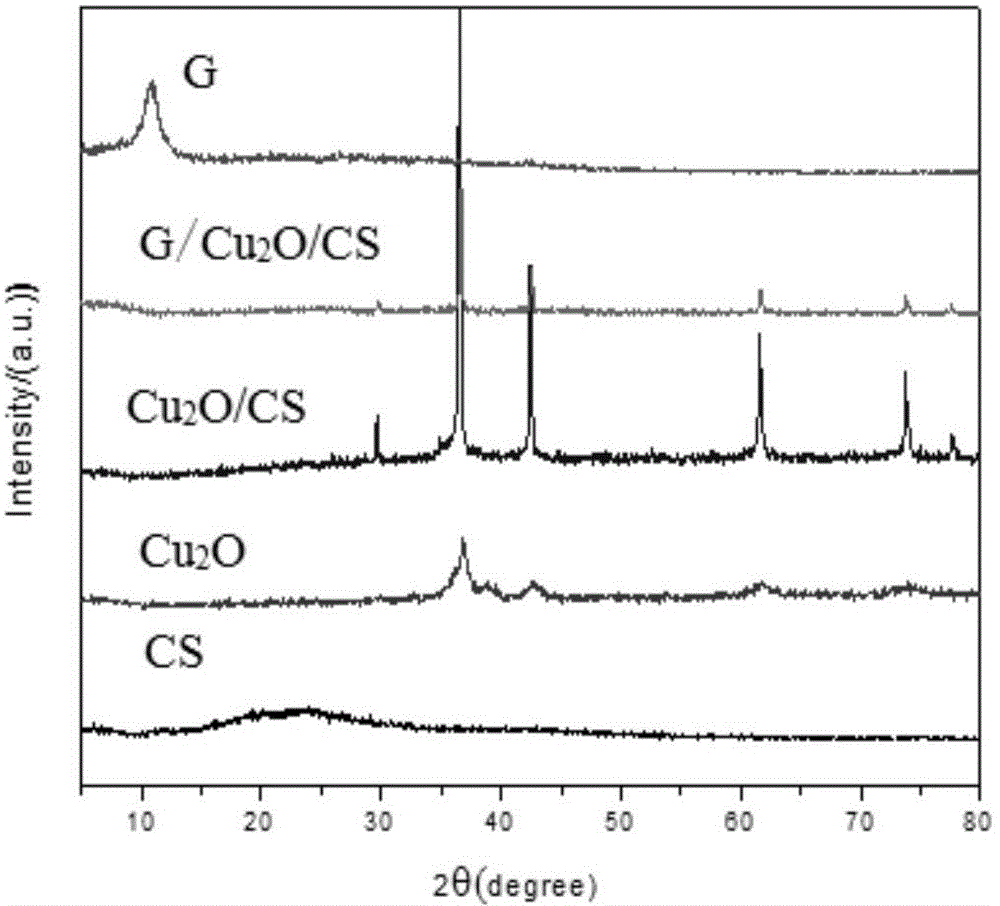

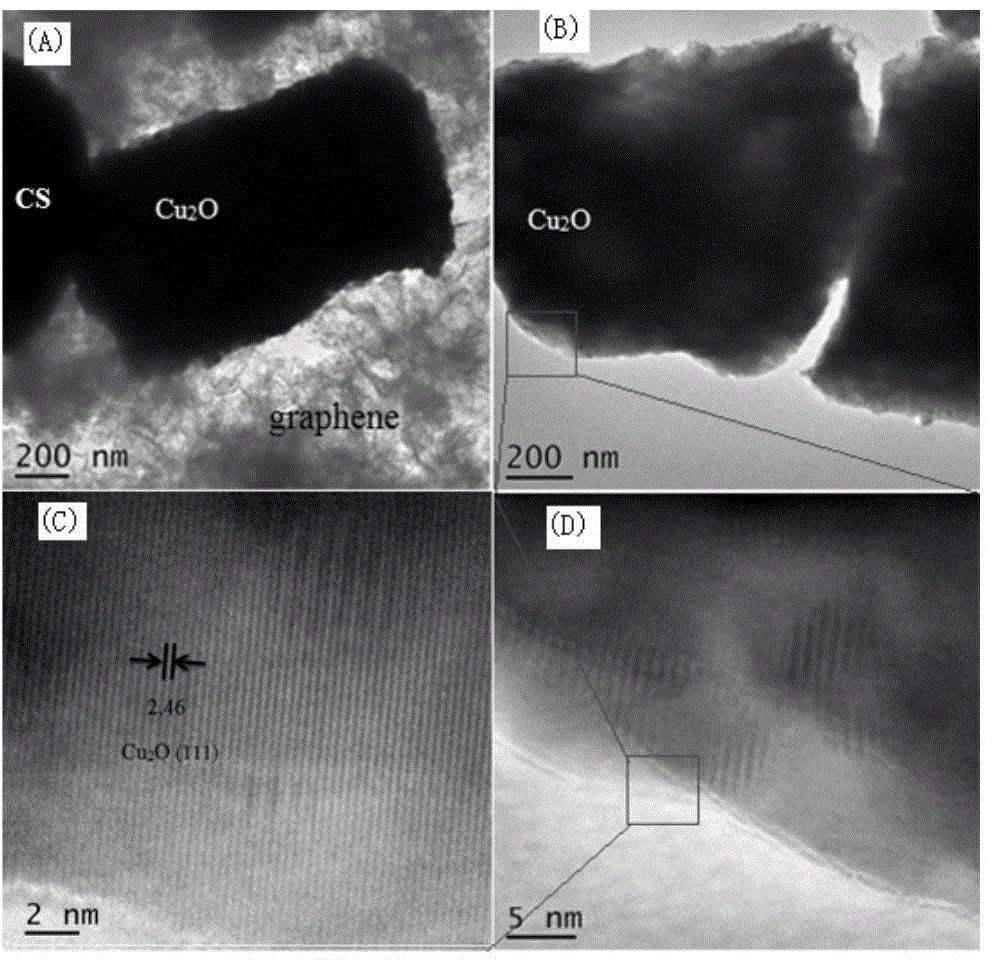

[0052] The graphene / chitosan / cuprous oxide composite material of this embodiment includes the following components in parts by weight: 1 part of graphene, 1 part of chitosan, and 4 parts of cuprous oxide.

[0053] The preparation method of the graphene / chitosan / cuprous oxide composite material of the present embodiment, concrete operation steps are as follows:

[0054] 1) Preparation of graphene: Weigh 1g of graphite, 4g of potassium permanganate, and 30mL of concentrated sulfuric acid, put them in the refrigerator together with the reaction kettle, freeze at 0°C for 1.5h, add each raw material into a polytetrafluoroethylene bottle, put Take out the reaction kettle, react at 80°C for 1 hour, open it quickly after cooling, pour the reactant into a 500mL beaker, add 150mL water to stir, and add 4ml hydrogen peroxide dropwise, the color turns golden yellow. After stirring for 1 hour, centrifuge, wash with 0.5% HCl and deionized water until pH = 7, put it into a cell pulverizer to...

Embodiment 2

[0060] The graphene / chitosan / cuprous oxide composite material of this embodiment includes the following components in parts by weight: 2 parts of graphene, 3 parts of chitosan, and 3 parts of cuprous oxide.

[0061] The preparation method of the graphene / chitosan / cuprous oxide composite material of the present embodiment, concrete operation steps are as follows:

[0062] 1) Preparation of graphene: Weigh 1g of graphite, 3g of potassium permanganate, and 20mL of concentrated sulfuric acid, put them in the refrigerator together with the reaction kettle, freeze at -4°C for 1 hour, add each raw material into a polytetrafluoroethylene bottle, put Take out the reaction kettle after reacting at 120°C for 1 hour, open it quickly after cooling, pour the reactant into a 500mL beaker, add 150mL water to stir, and add 3ml hydrogen peroxide dropwise, the color turns golden yellow. After stirring for 1 hour, centrifuge, wash with 0.1% HCl and deionized water until pH = 7, put it into a cell...

Embodiment 3

[0068] The graphene / chitosan / cuprous oxide composite material of this embodiment includes the following components in parts by weight: 3 parts of graphene, 2 parts of chitosan, and 6 parts of cuprous oxide.

[0069] The preparation method of the graphene / chitosan / cuprous oxide composite material of the present embodiment, concrete operation steps are as follows:

[0070] 1) Preparation of graphene: Weigh 3g of graphite, 8g of potassium permanganate, and 150mL of concentrated sulfuric acid, put them in the refrigerator together with the reaction kettle, freeze at -4°C for 1 hour, add each raw material into a polytetrafluoroethylene bottle, put Take out the reaction kettle after reacting at 100°C for 1.5h, open it quickly after cooling, pour the reactant into a 500mL beaker, add 150mL water to stir, and add 5ml hydrogen peroxide dropwise, the color turns golden yellow. After stirring for 1 hour, centrifuge, wash with 2% HCl and deionized water until pH = 7, put it into a cell pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com