Nano-precious metal catalyst and preparation method thereof

A noble metal catalyst and noble metal technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, catalyst protection, etc., can solve the problems of low-temperature hydrogenation activity, complex preparation process, and difficult application , to achieve good low-temperature hydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

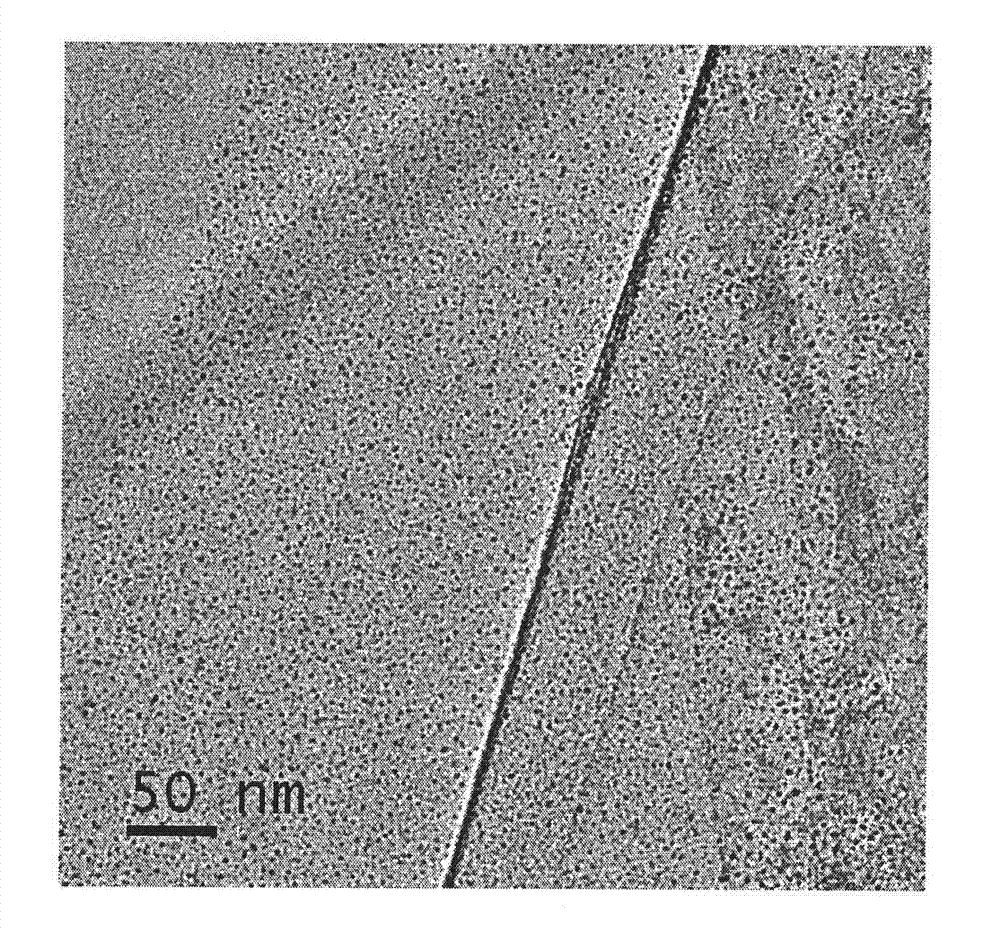

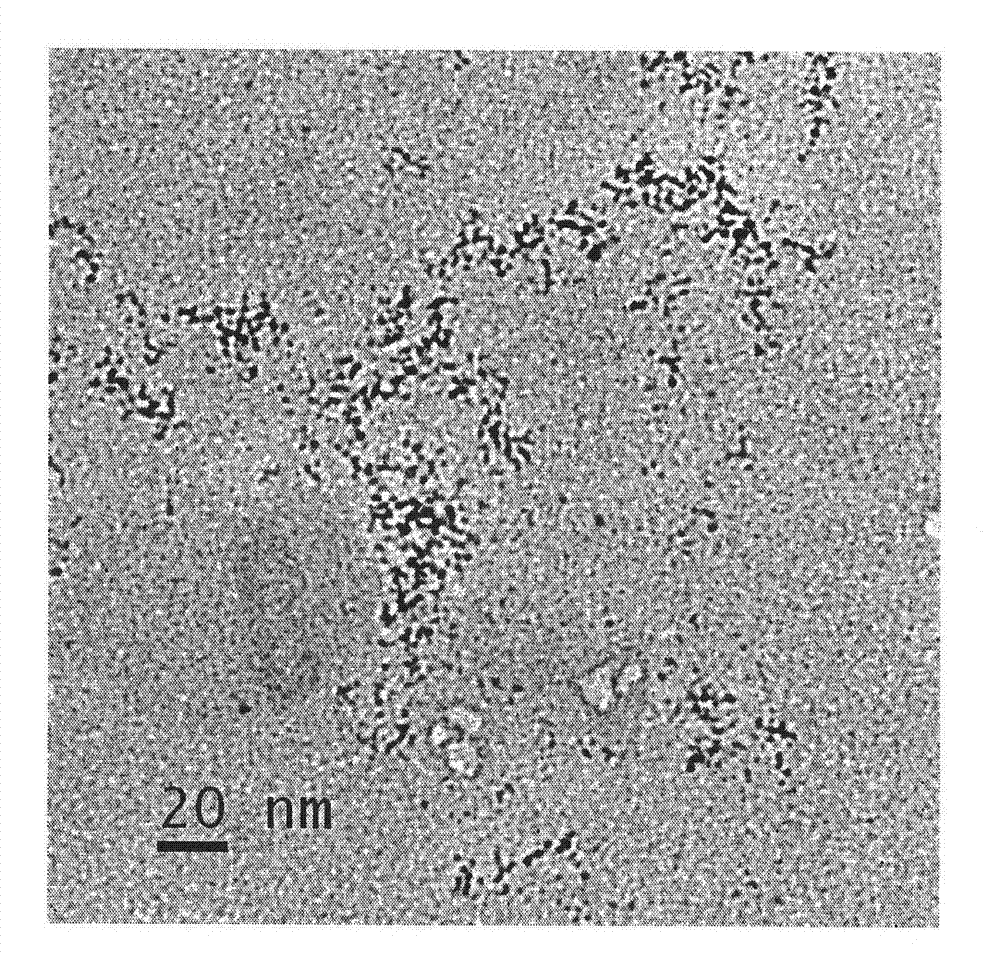

[0025] Weigh 30g of polyvinyl alcohol, add 270g of deionized water, let it stand for 1 hour, and heat and dissolve in a water bath at 90°C for 3 hours to obtain a transparent solution. Add 40ml ruthenium trichloride aqueous solution to above-mentioned PVA solution, its concentration is 7mg Ru / ml H 2 O, stir evenly, add 30ml of 0.03g / ml NaOH aqueous solution dropwise under stirring, and keep the temperature at 95°C for 2 hours to obtain a black solution. The solution was dropped onto a copper grid to dry, and the transmission electron microscope photos were as follows: figure 1 , figure 2 shown.

Embodiment 2

[0027] Weigh 30g of polyvinyl alcohol, add 270g of deionized water, let it stand for 1 hour, place it in an ordinary household microwave oven and heat it on high heat for 5 minutes to obtain a transparent solution. Add 40ml ruthenium trichloride aqueous solution to above-mentioned PVA solution, its concentration is 7mg Ru / ml H 2 O, stir evenly, add 30ml of 0.03g / ml NaOH aqueous solution dropwise under stirring, and keep the temperature at 95°C for 2 hours to obtain a black solution.

Embodiment 3

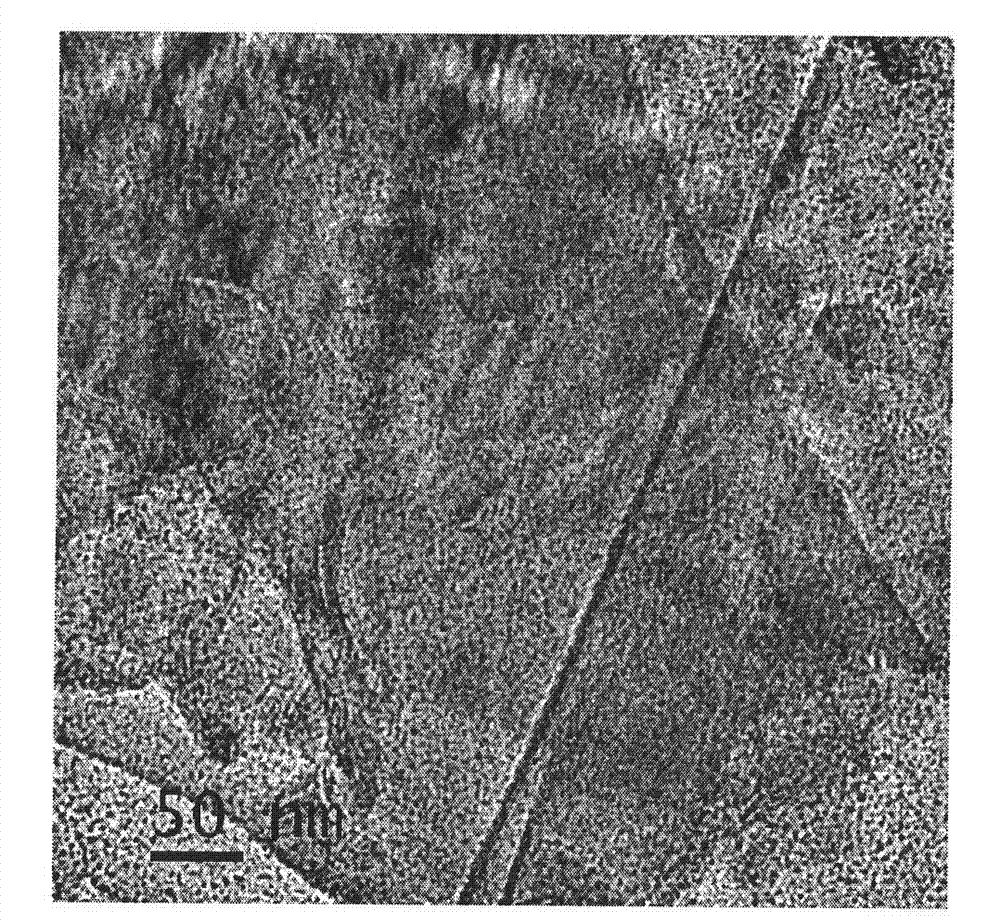

[0029] Weigh 20g of polyvinyl alcohol, add 180g of deionized water, let it stand for 1 hour, place it in a common household microwave oven and heat it on high heat for 5 minutes to obtain a transparent solution. In above-mentioned PVA solution, add 40ml ruthenium trichloride aqueous solution, its concentration is 4mg Ru / ml H 2 O, stir evenly, add dropwise 15ml 0.03g / ml NaOH aqueous solution under stirring, place in microwave oven and react for 10 minutes to obtain black solution. The solution was dropped onto a copper grid to dry, and the transmission electron microscope photos were as follows: image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com