Preparation method of lithium abundant cathode material for lithium ion battery

A lithium-rich cathode material, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor control of co-precipitation process, difficult dispersion and precipitation of nickel, cobalt, and manganese, and poor batch stability. , to achieve the effect of good batch stability, excellent electrochemical performance, and improved rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

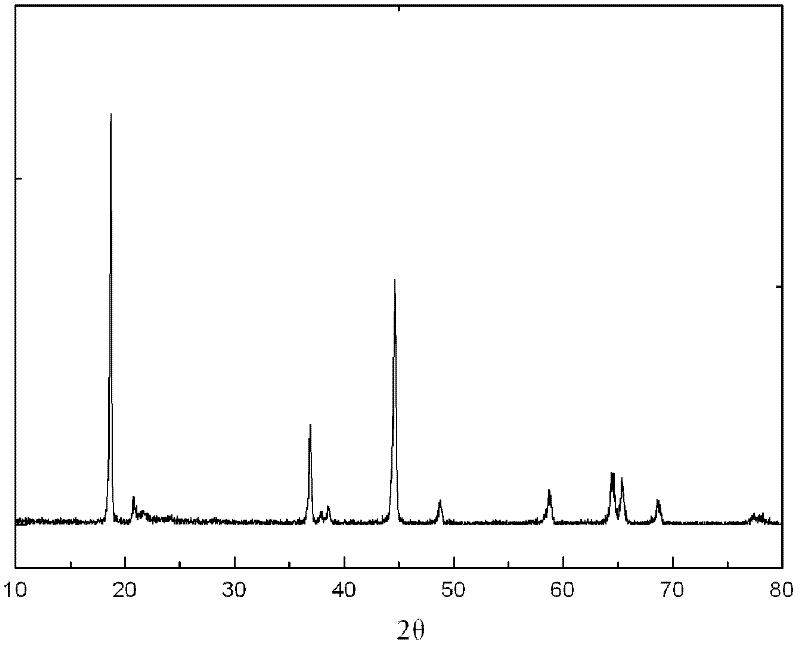

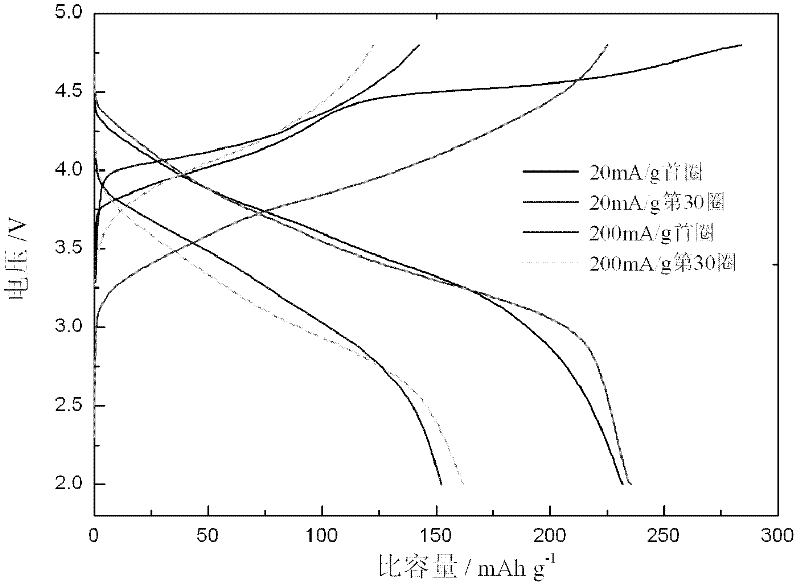

Embodiment 1

[0014] At 25°C, add 1.224 grams of lithium acetate to 50 grams of deionized water and stir until completely dissolved to obtain a lithium acetate solution; simultaneously add 0.497 grams of nickel acetate, 0.249 grams of cobalt acetate and 1.225 grams of manganese acetate to 100 grams of deionized water and stir until Completely dissolve to obtain a transition metal salt solution; add lithium acetate solution dropwise to the transition metal salt solution under stirring, continue stirring for 2 hours, and then transport it to a spray dryer at a feed rate of 3 mL / min by a metering pump for spray drying Granulate to obtain the precursor powder. The inlet temperature of the spray dryer is 200°C, and the outlet temperature is 110°C; the precursor powder is placed in a high-temperature furnace, and the temperature is raised at a heating rate of 10°C / min in an air atmosphere, and the temperature is kept at 900°C Calcined for 10 hours, then cooled to room temperature at a cooling rate...

Embodiment 2

[0017]At 25°C, add 1.122 grams of lithium acetate to 50 grams of deionized water and stir until completely dissolved to obtain a lithium acetate solution; simultaneously add 0.746 grams of nickel acetate, 0.125 grams of cobalt acetate and 1.348 grams of manganese acetate to 100 grams of deionized water and stir until Completely dissolve to obtain a transition metal salt solution; add the lithium acetate solution dropwise to the transition metal salt solution under stirring, continue stirring for 1.5 hours, and then transport it to a spray dryer at a feed rate of 6 mL / min by a metering pump for spray drying Granulate to obtain the precursor powder. The inlet temperature of the spray dryer is 210°C, and the outlet temperature is 120°C; the precursor powder is placed in a high-temperature furnace, and the temperature is raised at a heating rate of 10°C / min in an air atmosphere, and the temperature is kept at 800°C Calcined for 10 hours, then cooled to room temperature at a cooling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com