Environmentally-friendly high-seepage epoxy grouting material and preparation method and application thereof

An epoxy grouting, high-penetration technology, applied in protection devices, infrastructure repair, construction, etc., can solve the problems of inability to deal with cracks, decreased mechanical properties of materials, and high cost of diluents, and achieves simple and convenient preparation and construction technology. , good mechanical properties, excellent permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

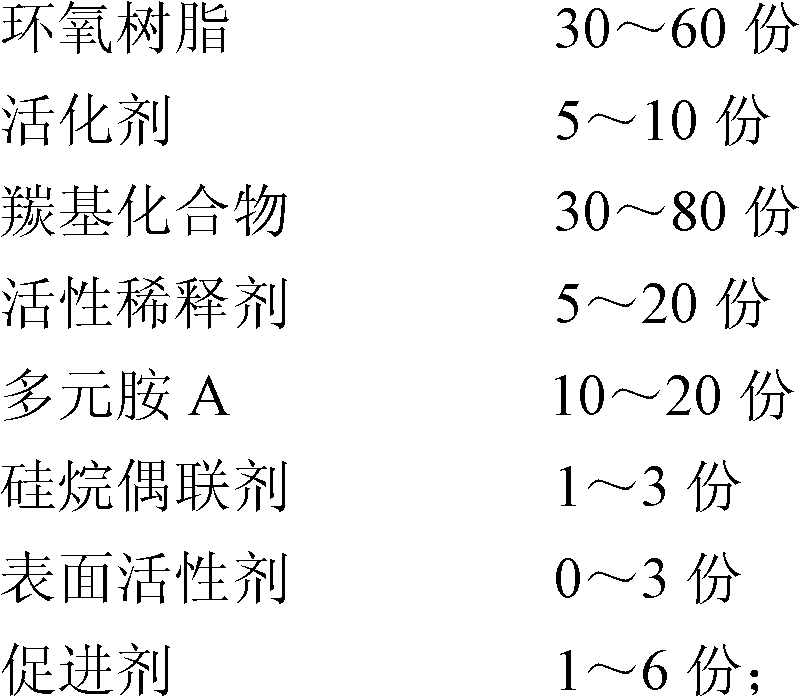

Method used

Image

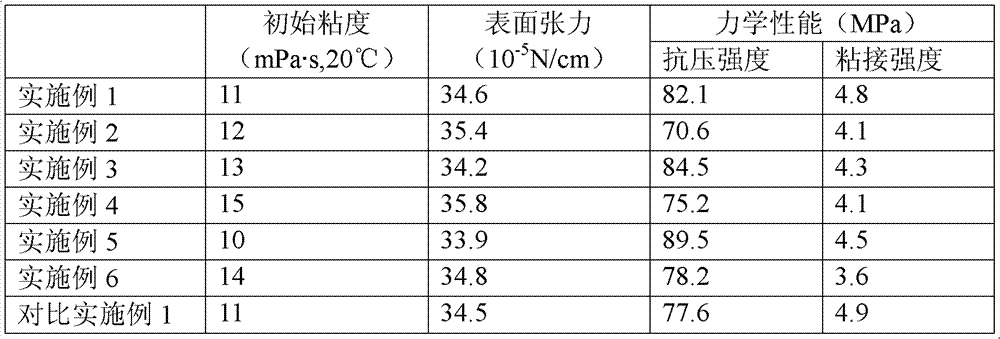

Examples

Embodiment 1

[0034] (1) Preparation of activator: mix 25 parts by mass of diethylenetriamine, 20 parts by mass of p-methoxyphenol and 20 parts by mass of formaldehyde (mass percentage 37%, the same below), add catalyst NaOH (the total amount of the aforementioned substances used 1% of the mass), heated to 40°C for 20 hours under stirring, and then depressurized and fully dehydrated to obtain the activator.

[0035] (2) Preparation of environment-friendly high-permeability epoxy grouting material:

[0036] Liquid A: 50 parts by mass of epoxy resin E44, 30 parts by mass of benzaldehyde, 30 parts by mass of acetone, 10 parts by mass of octyl glycidyl ether and 3 parts by mass of stearic acid were mixed and obtained;

[0037] Liquid B: 12 parts by mass of diethylenetriamine, 6 parts by mass of activator, 1 part by mass of γ-aminopropyltrimethoxysilane and 3 parts by mass of 2,4,6-tris(dimethylamino)phenol ;

[0038] Mix liquid A and liquid B during use to obtain a high-permeability and hig...

Embodiment 2

[0040] (1) Preparation of activator: mix 45 parts by mass of diethylenetriamine, 25 parts by mass of p-cresol, 5 parts by mass of p-aminophenol and 80 parts by mass of formaldehyde, add catalyst potassium hydroxide (the total mass of the aforementioned substances used 1%), heated to 50 ° C under stirring for 18 hours, and then depressurized and fully dehydrated to obtain the activator.

[0041] (2) Preparation of environment-friendly high-permeability epoxy grouting material:

[0042] Liquid A: 40 parts by mass of epoxy resin E51, 30 parts by mass of benzaldehyde, 30 parts by mass of methyl ethyl ketone, 10 parts by mass of ethylene glycol diglycidyl ether and 1 part by mass of polyethylene glycol monostearate were mixed evenly;

[0043] Liquid B: obtained by mixing 15 parts by mass of triethylenetetramine, 8 parts by mass of an activator, 3 parts by mass of γ-aminopropyltriethoxysilane and 6 parts by mass of triethanolamine;

[0044] Mix liquid A and liquid B during use to ...

Embodiment 3

[0046] (1) Preparation of activator: same as step (1) of Example 1.

[0047] (2) Preparation of environment-friendly high-permeability epoxy grouting material:

[0048] Liquid A: 40 parts by mass of epoxy resin E44, 30 parts by mass of methylbenzaldehyde, 15 parts by mass of acetone, 20 parts by mass of 1,4-butanediol diglycidyl ether and 2 parts by mass of ethylene glycol monostearate Mixed to get;

[0049]Liquid B: obtained by mixing 15 parts by mass of tetraethylenepentamine, 6 parts by mass of activator, 1 part by mass of γ-glycidyl etheroxypropyltrimethoxysilane and 5 parts by mass of dimethyl-p-methylaniline;

[0050] Mix liquid A and liquid B during use to obtain a high-permeability and high-strength epoxy grouting material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com