Preparation method of water-insoluble corn dietary fiber with high oil-holding capacity

A water-insoluble, dietary fiber technology, applied in food preparation, food science, application, etc., can solve the problems of poor physical and chemical properties of water-insoluble dietary fiber, inability to fully exert physiological effects, etc., to improve the degree of comprehensive development and utilization, Low cost and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of intermediate product water-insoluble corn fiber

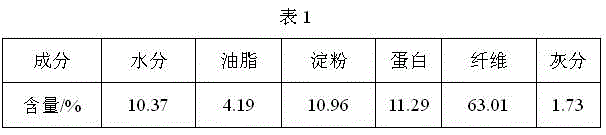

[0039] First, the corn seed coats are screened, washed, dried, pulverized with a pulverizer, and passed through a 100-mesh sieve. The fat content of corn husk is only about 4%, and it can not be removed for lipophilic occasions.

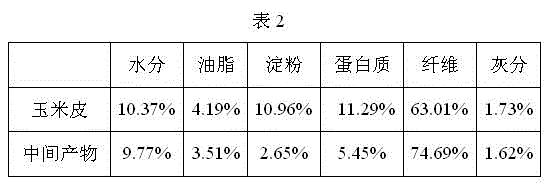

[0040] Take the sieved corn bran powder and water in a mass ratio of 1:20 and make a slurry, adjust the pH to 7.5 with dilute alkali, add 1398 neutral protease, the enzyme dosage is 2000u / gDS, and enzymatically hydrolyze at 45°C 90min, then use dilute hydrochloric acid to adjust ph=6, add high-temperature-resistant a-amylase equivalent to 0.5% of dry corn bran powder, enzymolyze at 100°C for 60min, cool down to 60°C after the reaction, and then add equivalent Continuing to hydrolyze 0.3% glucoamylase of dry corn bran powder at 60°C for 120 minutes, heat to 90°C to inactivate the enzyme activity after the reaction is completed, filter the reverse enzymolysis solution after cool...

Embodiment 2

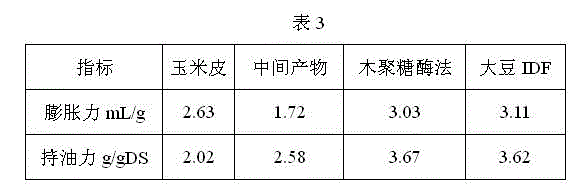

[0049] Take 100g of corn seed coat powder that has been screened, dried and crushed and passed through a 100-mesh sieve, add 1700mL of water to make a slurry, adjust the pH to 7.6 with dilute sodium hydroxide solution, add 300000u of 1398 neutral protease, and enzyme at 45°C Decompose for 85 minutes; adjust ph=5.6 with dilute hydrochloric acid, add 0.05g of high-temperature-resistant a-amylase, hydrolyze in boiling water bath for 85min, then cool down to 56°C, add 0.03g of glucoamylase, keep 56°C for 150min, and then heat to Incubate at 97°C for 15 minutes to inactivate the enzyme, cool down and filter, then wash and filter the obtained solid to obtain insoluble dietary fiber, then add it to 1300mL of distilled water, stir evenly, use dilute hydrochloric acid to pH 5.0, add 18mL of xylanase , control the temperature at 60°C, enzymolyze for 60 minutes, filter the enzymolyzate after cooling down, dry the obtained solid and grind it to obtain 89.5g of finished product, the measure...

Embodiment 3

[0051] Take 90g of corn seed coat powder that has been screened, dried, and crushed and passed through a 100-mesh sieve, add 1300mL of water to make a slurry, adjust the pH to 7.3 with dilute sodium hydroxide solution, add 300,000u of 1398 neutral protease, and enzyme at 46°C Decompose for 60 minutes, adjust ph=5.8 with dilute hydrochloric acid, add 0.05g of high temperature resistant a-amylase, hydrolyze in boiling water bath for 100min, then cool down to 56°C, add 0.02g of glucoamylase, keep 56°C for 180min, then heat to Incubate at 95°C for 20 minutes to inactivate the enzyme, cool down to 60°C and filter the enzymolysis solution, wash the obtained solid with water and suction filter, dissolve it in water to make a slurry and adjust the pH value to 5.5 with dilute hydrochloric acid, add 15mL of xylanase, and stir for 70 minutes for enzymolysis After cooling down, the reaction liquid was filtered by suction, the obtained solid was dried, and 82.1g of finished product was obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com