Passivation Method of Cavity Surface of f-p Cavity Semiconductor Laser

A laser and semiconductor technology, applied in the structure of optical resonant cavity, ion implantation plating, coating, etc., can solve the problem of inapplicability of GaN-based and ZnO-based semiconductor lasers, the inability to effectively reduce dangling bonds and surface states, and unfavorable Reduce laser cavity surface absorption and other problems, achieve the effect of increasing optical catastrophe damage threshold, improving stability and reliability, and increasing output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

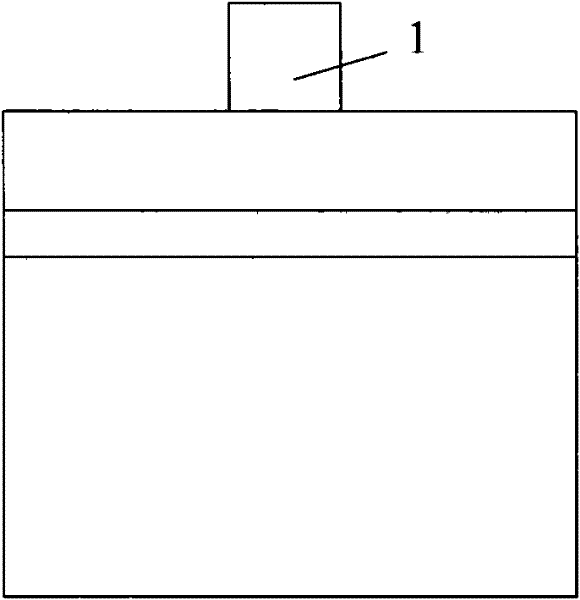

[0027] This embodiment uses a ridge-type GaN-based laser. The schematic diagram of the ridge GaN-based laser chip is attached figure 2 As shown, the active region of the laser is an InGaN / GaN multiple quantum well, and the top of the chip is a ridge type 1.

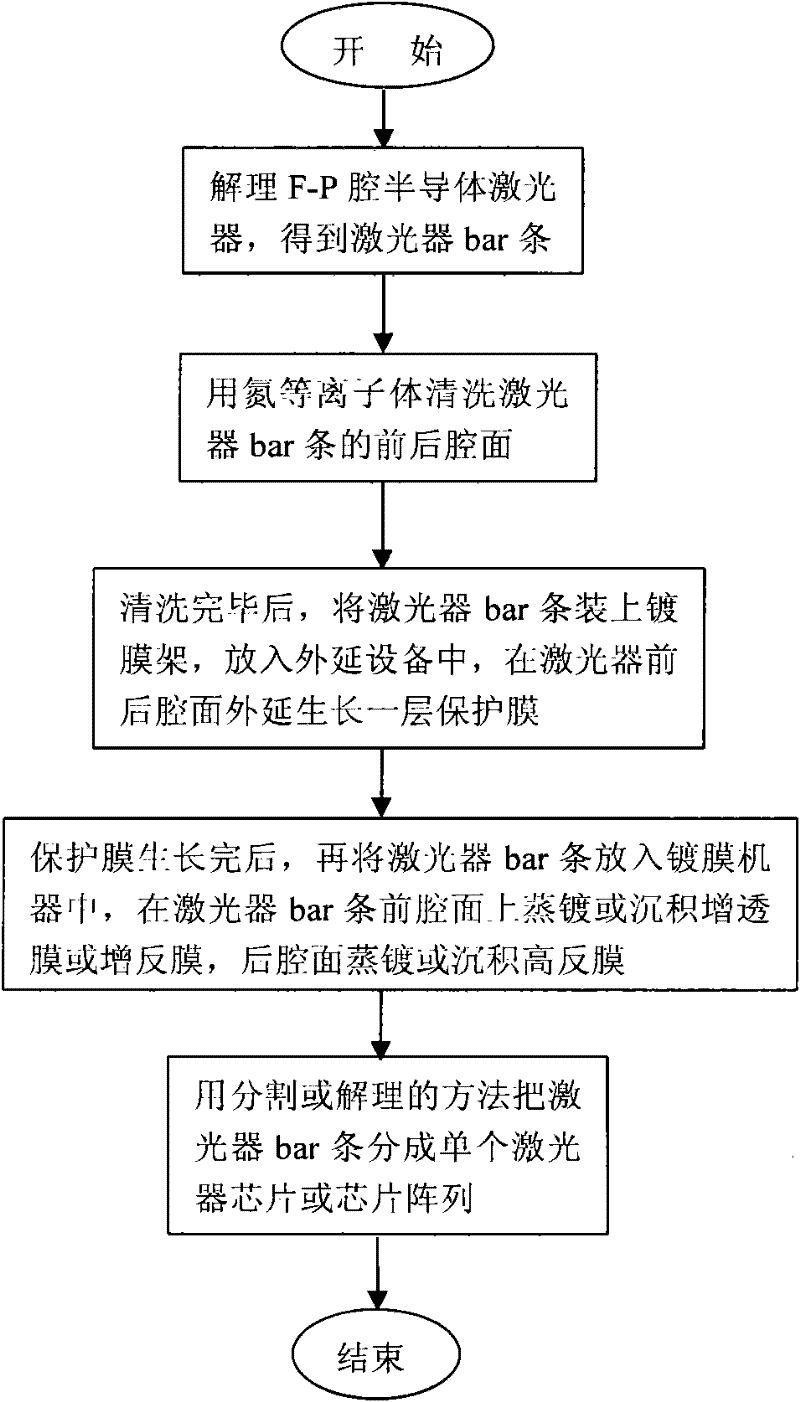

[0028] This method mainly comprises the following steps:

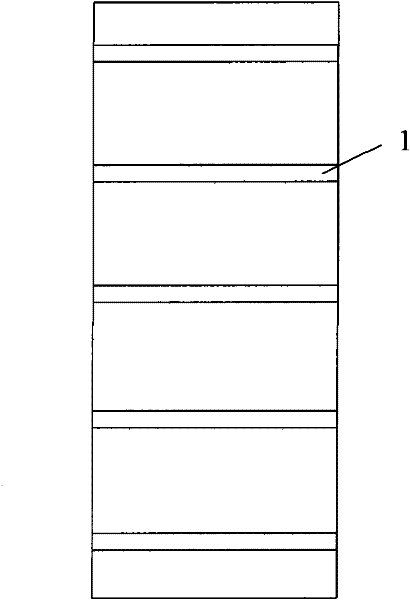

[0029] 1. Cleavage the F-P cavity-ridge GaN-based semiconductor laser to obtain a laser bar. The schematic diagram of the laser bar is attached image 3 shown;

[0030] 2. Clean the front and rear cavity surfaces of the laser bar with nitrogen plasma;

[0031] 3. After cleaning, install the laser bar on the coating frame, put it into the magnetron plasma sputtering system, and epitaxially grow a layer of AlON protective film 2 on the front and rear cavity surfaces of the laser, as attached Figure 4 shown. When epitaxially growing the AlON protective film 2, control its growth rate to be 2nm / min, not too fast, so that the epitaxial AlON protective film 2 gro...

Embodiment 2

[0036] This embodiment uses a ridge-type GaN-based laser. The schematic diagram of the ridge GaN-based laser chip is attached figure 2 As shown, the active region of the laser is an InGaN / GaN multiple quantum well, and the top of the chip is a ridge type 1.

[0037] This method mainly comprises the following steps:

[0038] 1. Cleavage the F-P cavity-ridge GaN-based semiconductor laser to obtain a laser bar. The schematic diagram of the laser bar is attached image 3 shown;

[0039] 2. Clean the front and rear cavity surfaces of the laser bar with nitrogen plasma;

[0040] 3. After cleaning, install the laser bar on the coating frame, put it into the electron cyclotron resonance plasma sputtering system, and epitaxially grow a layer of Al on the front and rear cavity surfaces of the laser 2 o 3 Protective film 2, if attached Figure 4 shown. Epitaxially grown Al 2 o 3 For protective film 2, control its growth rate to be 4nm / min, not too fast, so that the epitaxial Al...

Embodiment 3

[0045] This embodiment uses a ridge-type GaN-based laser. The schematic diagram of the ridge GaN-based laser chip is attached figure 2 As shown, the active region of the laser is an InGaN / GaN multiple quantum well, and the top of the chip is a ridge type 1.

[0046] This method mainly comprises the following steps:

[0047] 1. Cleavage the F-P cavity-ridge GaN-based semiconductor laser to obtain a laser bar. The schematic diagram of the laser bar is attached image 3 shown;

[0048] 2. Clean the front and rear cavity surfaces of the laser bar with nitrogen plasma;

[0049] 3. After cleaning, install the laser bar on the coating frame, put it into the MOCVD epitaxy equipment, and epitaxially grow a layer of SiAlON protective film 2 on the front and rear cavity surfaces of the laser, as attached Figure 4 shown. When epitaxially growing the SiAlON protective film 2, control its growth rate to be 5nm / min, not too fast, so that the epitaxial SiAlON protective film 2 grows on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com