A method for preparing crocin-I by high-speed countercurrent chromatography

A technology of high-speed countercurrent chromatography and crocin, which is applied in the field of preparing crocin-I by high-speed countercurrent chromatography, can solve the problems of complex operation and small preparation volume, achieve large separation volume, fast separation speed, and sample lossless effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

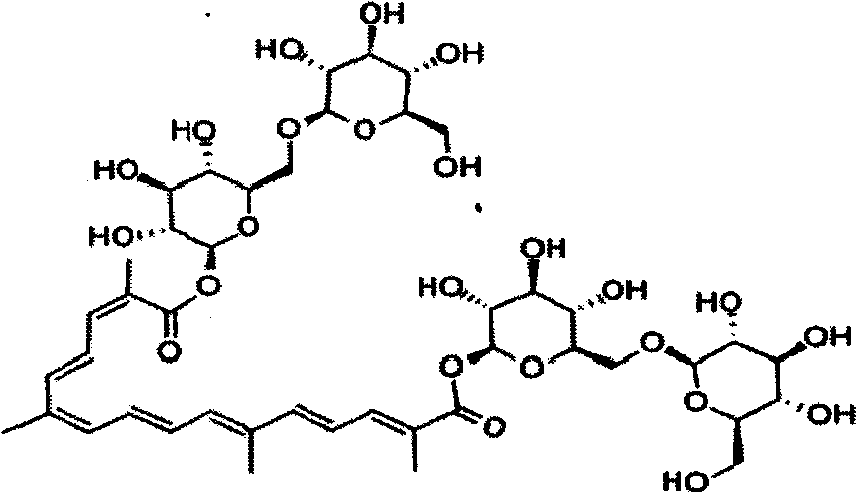

Image

Examples

Embodiment 1

[0016] Take ethyl acetate, ethanol, and water, mix them in a ratio of 7:4:5, let them stand in a separatory funnel for 12 hours, and separate the upper and lower phases. Take the upper phase and fill the high-speed countercurrent chromatographic column, turn the main engine at a speed of 700rpm, pump the lower phase into the mobile phase, and when the mobile phase flows out, adjust the flow rate to 4ml / min, and take the mobile phase to dissolve gardenia yellow with a color value of 400 Pigment 1g, injected by the injection valve, detected by SP-200 ultraviolet detector, collected the target components according to the spectrum, concentrated fraction under reduced pressure and dried in vacuum to obtain brownish red powder, which was analyzed as crocin by mass spectrometry, nuclear magnetic resonance and infrared -1, content is 98.7%.

Embodiment 2

[0018] Take ethyl acetate, ethanol, and water, mix them in a ratio of 5:3:4, let them stand in a separatory funnel for 8 hours, and separate the upper and lower phases. Take the upper phase and fill the high-speed countercurrent chromatographic column, turn the main engine at a speed of 1200rpm, pump the lower phase into the mobile phase, and when the mobile phase flows out, adjust the flow rate to 2ml / min, and take the mobile phase to dissolve gardenia yellow with a color value of 400 Pigment 1g, injected by the injection valve, detected by SP-200 ultraviolet detector, collected the target components according to the spectrum, concentrated fractions under reduced pressure and dried in vacuum to obtain brownish red powder crocin-I, the HPLC detection content was 98.1%.

Embodiment 3

[0020] Take ethyl acetate, ethanol, and water, mix them in a ratio of 6:4:5, let them stand in a separatory funnel for 12 hours, and separate the upper and lower phases. Take the upper phase and fill the high-speed countercurrent chromatographic column, turn the main engine at a speed of 800rpm, pump the lower phase into the mobile phase, and when the mobile phase flows out, adjust the flow rate to 1ml / min, and take the mobile phase to dissolve gardenia yellow with a color value of 400 Pigment 1g is sampled by the injection valve, detected by the SP-200 ultraviolet detector, and the target components are collected according to the spectrum, and the concentrated fraction is vacuum-dried to obtain brownish red powder crocin-I, and the HPLC detection content is 98.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com