A method for preparing nanoscale lithium iron phosphate by self-sacrificing template method

A technology of lithium iron phosphate and sacrificial templates, which is applied in the field of electrochemistry, can solve the problems of difficult control of particle shape, complicated preparation process, narrow size distribution range, etc., and achieve good reversibility of lithium deintercalation, uniform chemical composition, The effect of uniform mixing of reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

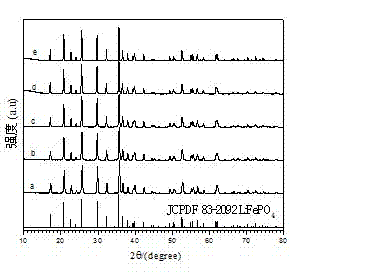

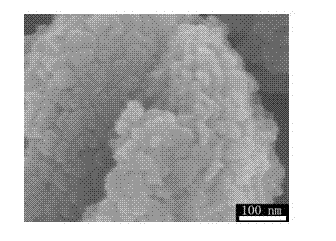

Embodiment 1

[0037] 1. With FeCl 3 and NH 4 h 2 PO 4 The raw materials are respectively prepared into aqueous solutions with a concentration of 0.1mol / L; according to Fe 3+ :PO 4 3+ The molar ratio is 1:1.1, weighed and placed in the reaction container, and stirred at a speed of 30 r / min, then added ammonia water to adjust the pH of the solution to 4, and reacted at 80°C for 5 hours to obtain amorphous iron phosphate precipitation ; After the precipitate is filtered, it is washed with deionized water and alcohol until the washing liquid is neutral to remove impurity ions, and then the precipitate is dried in an oven at 60°C for 10 hours to obtain nano-scale FePO 4 . wxya 2 O, then calcined in an air atmosphere at 550°C for 8 hours, then slowly cooled to room temperature with the furnace, and then ground and pulverized to obtain a crystalline nano-iron phosphate template; weigh lithium hydroxide and the prepared iron phosphate template in a molar ratio of 1.01:1 At the same time, af...

Embodiment 2

[0043] with FeCl 3 and (NH 4 ) 2 HPO 4 The raw materials are respectively prepared into aqueous solutions with a concentration of 1mol / L; according to Fe 3+ :PO 4 3+ The molar ratio is 1:1.2, weighed and placed in the reaction container, and stirred at a speed of 40 r / min, then added ammonia water to adjust the pH of the solution to 6, and reacted at 90°C for 5 hours to obtain amorphous iron phosphate precipitation ; After filtering the precipitate, wash it with deionized water and alcohol until the washing liquid is neutral to remove impurity ions, and then dry the precipitate in an oven at 70°C for 10 hours to obtain nano-scale FePO 4 . wxya 2 O, then calcined in an air atmosphere at 600°C for 8 hours, then slowly cooled to room temperature with the furnace, and then ground and pulverized to obtain a crystalline nano-iron phosphate template; weigh lithium carbonate and the prepared iron phosphate template at a molar ratio of 0.51:1 At the same time, after adding 45g ...

Embodiment 3

[0047] With Fe(NO 3 ) 3 and NH 4 h 2 PO 4 The raw materials are respectively prepared into aqueous solutions with a concentration of 4mol / L; according to Fe 3+ :PO 4 3+ The molar ratio is 1:1.3, weighed and placed in a reaction container, and stirred at a speed of 40 r / min, then added ammonia water to adjust the pH of the solution to 3, and reacted at 70°C for 6 hours to obtain amorphous iron phosphate precipitation ; After the precipitate is filtered, it is washed with deionized water and alcohol until the washing liquid is neutral to remove impurity ions, and then the precipitate is dried in an oven at 90°C for 6 hours to obtain nano-scale FePO 4 . wxya 2 O, then calcined in an air atmosphere at 650°C for 12 hours, then slowly cooled to room temperature with the furnace, and then ground and pulverized to obtain a crystalline nano-iron phosphate template; weigh lithium acetate and the prepared iron phosphate template at a molar ratio of 1.03:1 At the same time, after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com