A kind of process method of carbon nanotube jet grinding nickel base alloy

A carbon nanotube, nickel-based alloy technology, applied in metal processing equipment, abrasive feeding devices, abrasives, etc., can solve the problems of poor fluidity of solid materials, difficult grinding process, difficult to take away heat, etc. Low, high processing quality, processing quality and the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

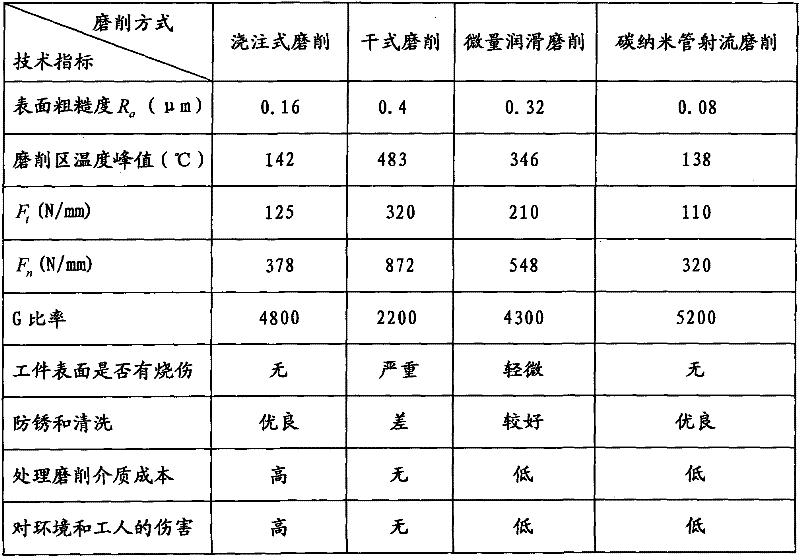

[0017] In order to prove the effectiveness of the carbon nanotube jet grinding process for nickel-based alloys, we did a comparative experiment between the carbon nanotube jet grinding nickel-based alloy process and pouring grinding, dry grinding, and minimal lubrication grinding. The following is only Provide a typical experimental situation:

[0018] Experimental conditions: SCHLEIFRING K-P36 precision CNC surface grinder, CBN grinding wheel, grinding wheel parameters: diameter 300mm, particle size: 240#, grinding wheel linear speed 65m / s, feed rate 0.5m / min; cutting depth 1.5 mm. The grade of nickel-based alloy material used in the test is: GH4145, and its hardness is HB330-400. Three-way piezoelectric grinding force measuring instrument (YDM-Ⅲ99), surface topography instrument (Talysurf), and infrared thermal imager (Thermovision A20M) were used to measure grinding force, surface microstructure and grinding zone temperature, respectively.

[0019] Experimental design: ① ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com