Magnesium alloy and aluminum alloy interlayer diffusion welding method

A diffusion welding and aluminum alloy technology, applied in welding equipment, metal material coating process, welding/welding/cutting articles, etc., can solve the problems of difficult control of welding process, low strength of welded joints, and difficulty in reliable connection, etc., to achieve The overall parallelism is good, the deformation is small, and it is beneficial to the effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

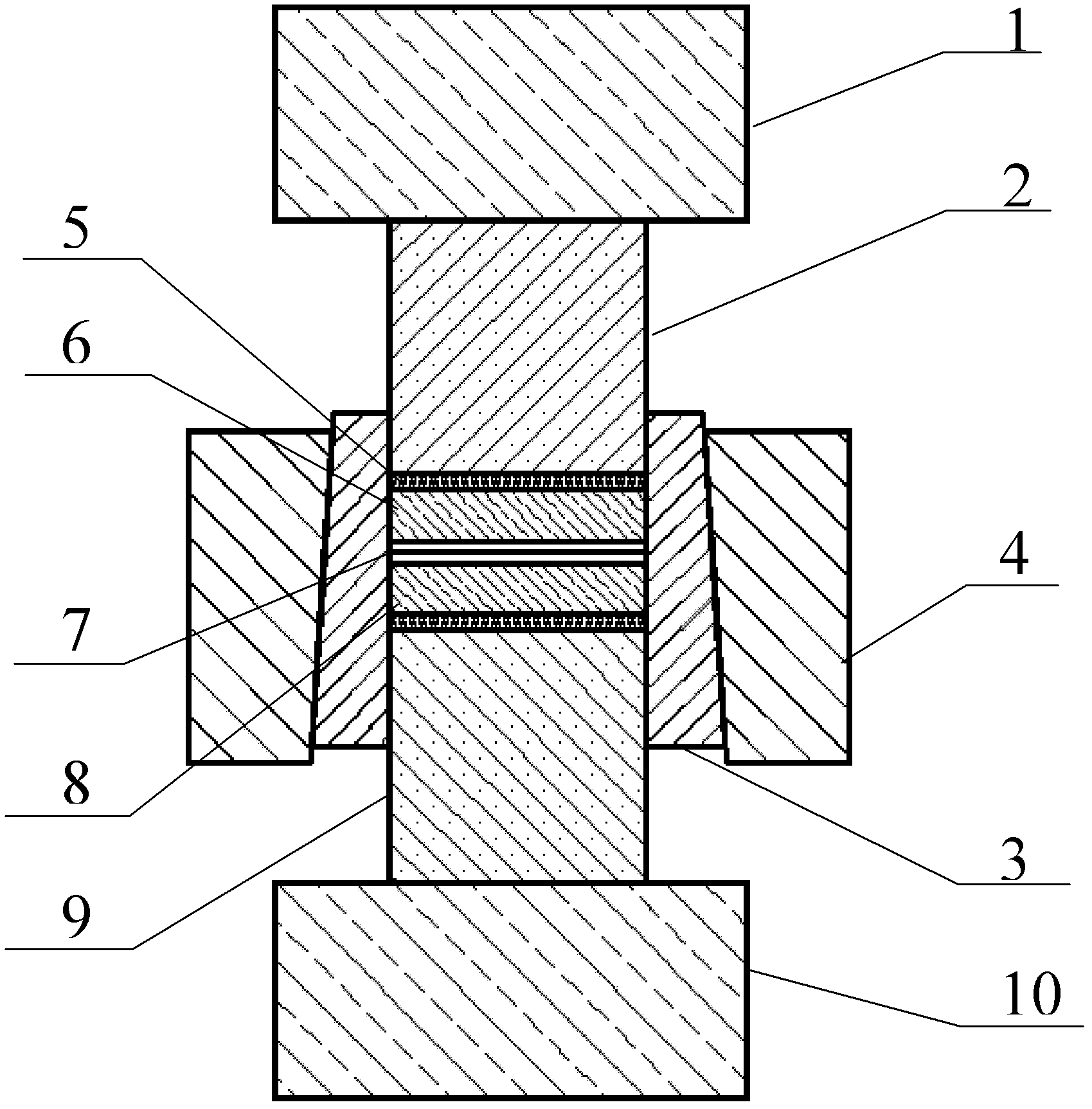

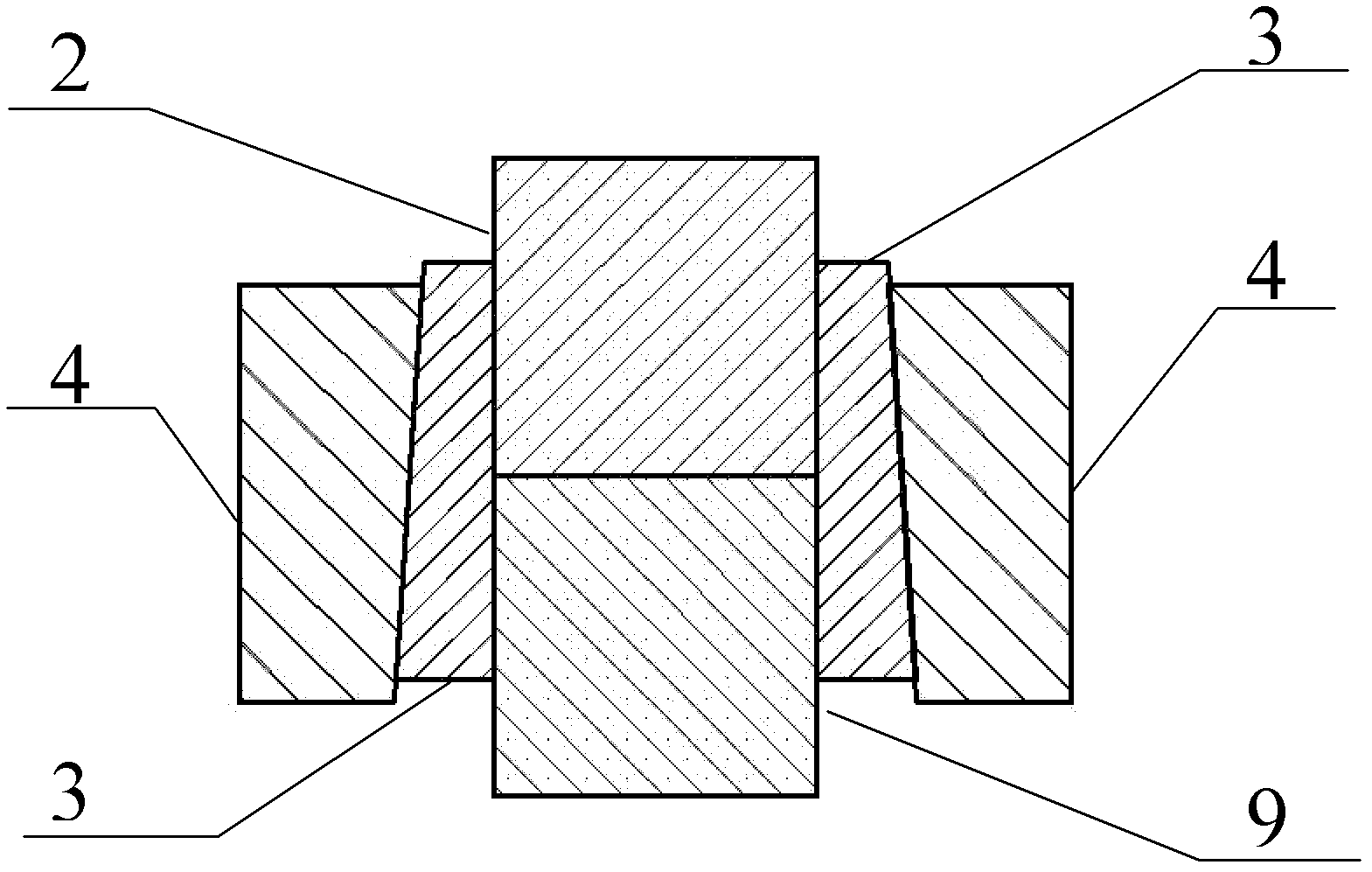

[0034] The magnesium alloy to be welded piece 8 and the aluminum alloy to be welded piece 6 are connected by diffusion welding, wherein: the magnesium alloy to be welded piece 8 is an MB2 magnesium alloy with a diameter of Φ23×2mm, and the aluminum alloy to be welded piece 6 is a diameter of Φ23×2mm to be LY12 aluminum alloy . The magnetron sputtering Cu film layer 7 has a thickness of 0.5 μm, and the diffusion bonding process conditions are: welding temperature 470° C., holding time 30 minutes, and welding pressure 3 MPa.

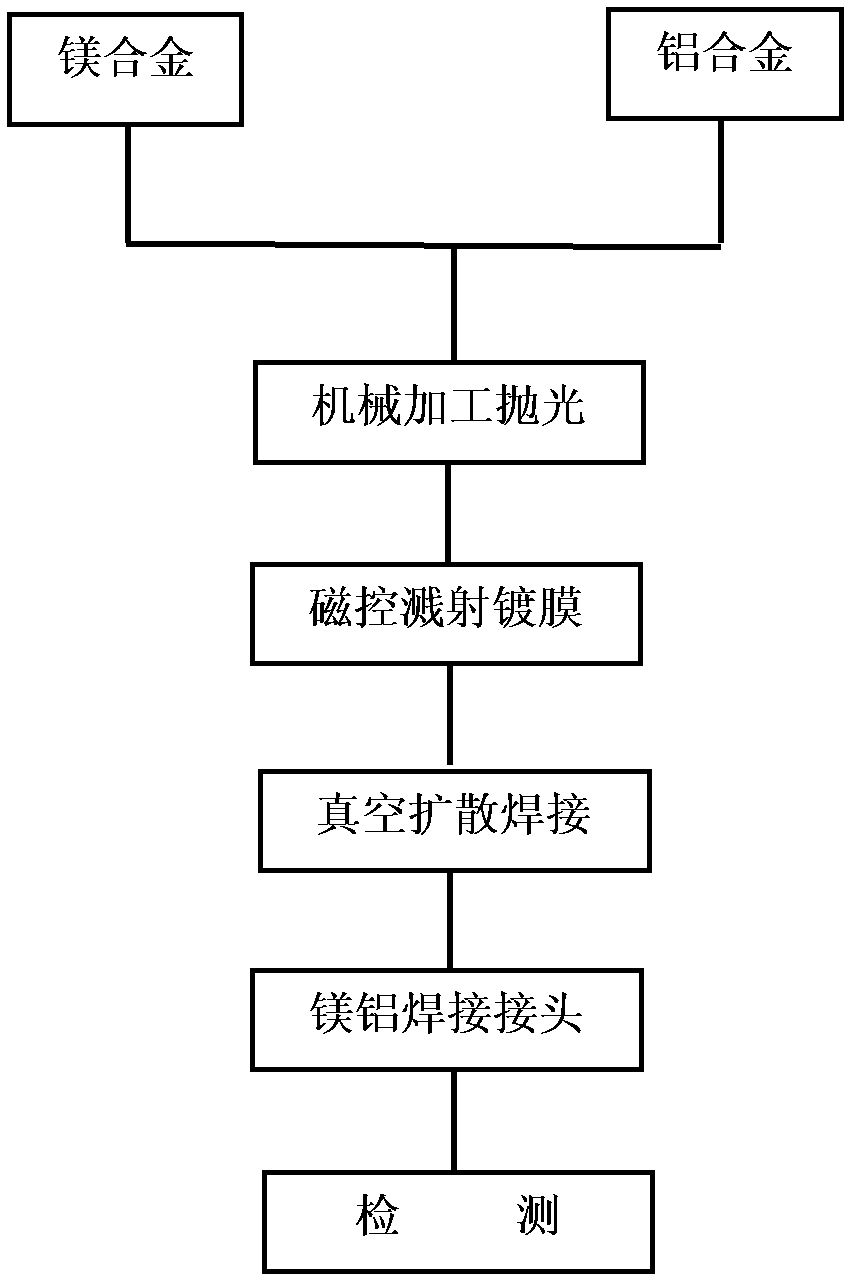

[0035] see figure 1 , the specific steps of carrying out diffusion welding of the magnesium alloy to-be-welded piece 8 and the aluminum alloy to-be-welded piece 6 are as follows:

[0036] 1. To be welded parts mechanical processing:

[0037] Magnesium alloys and aluminum alloys are processed into round sheets with ultra-precision surface grinders, and 1000 # , 1200 # SiC sandpaper and metallographic sandpaper No. 05, 06, and 07 were used to polish the ...

Embodiment 2

[0044]The magnesium alloy to be welded piece 8 and the aluminum alloy to be welded piece 6 are connected by diffusion welding, wherein: the magnesium alloy to be welded piece 8 is an MB2 magnesium alloy with a diameter of Φ23×2mm, and the aluminum alloy to be welded piece 6 is a diameter of Φ23×2mm to be LY12 aluminum alloy . The magnetron sputtering Cu film layer 7 has a thickness of 0.1 μm, and the diffusion bonding process conditions are: welding temperature 420° C., holding time 120 minutes, and welding pressure 10 MPa.

[0045] see figure 1 , the specific steps of carrying out diffusion welding of the magnesium alloy to-be-welded piece 8 and the aluminum alloy to-be-welded piece 6 are as follows:

[0046] 1. To be welded parts mechanical processing:

[0047] Magnesium alloys and aluminum alloys are processed into round sheets with ultra-precision surface grinders, and 1000 # , 1200 # SiC sandpaper and metallographic sandpaper No. 05, 06, and 07 were used to polish the...

Embodiment 3

[0054] The magnesium alloy to be welded piece 8 and the aluminum alloy to be welded piece 6 are connected by diffusion welding, wherein: the magnesium alloy to be welded piece 8 is an MB2 magnesium alloy with a diameter of Φ23×2mm, and the aluminum alloy to be welded piece 6 is a diameter of Φ23×2mm to be LY12 aluminum alloy piece. The magnetron sputtering Cu film layer 7 has a thickness of 0.3 μm, and the diffusion bonding process conditions are: welding temperature 440° C., holding time 60 minutes, and welding pressure 5 MPa.

[0055] see figure 1 , the specific steps of carrying out diffusion welding of the magnesium alloy to-be-welded piece 8 and the aluminum alloy to-be-welded piece 6 are as follows:

[0056] 1. To be welded parts mechanical processing:

[0057] Magnesium alloys and aluminum alloys are processed into round sheets with ultra-precision surface grinders, and 1000 # , 1200 # SiC sandpaper and metallographic sandpaper No. 05, 06, and 07 were used to polish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Parallelism | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com