Composite guide plate and preparation process thereof

A composite material and guide plate technology, which is applied in the field of guide plate and its preparation process, can solve the problems that the guide plate cannot meet the needs of actual use, cannot be mass-produced, and the preparation process is complicated, so as to prevent collapse and improve use. Longevity, strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

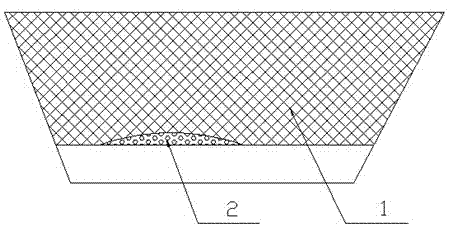

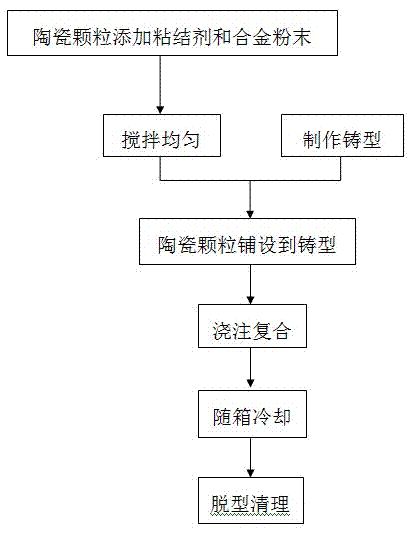

[0019] Such as figure 2 , 3 As shown, the composite material guide plate with tungsten carbide particles as the hard phase and Cr15 high chromium steel as the base material is prepared, and the preparation steps are as follows:

[0020] A. Select tungsten carbide particles with a particle size range of -40~+60 mesh, add 3% polyvinyl alcohol and 10% nickel powder according to the weight of the ceramic particles, and stir evenly;

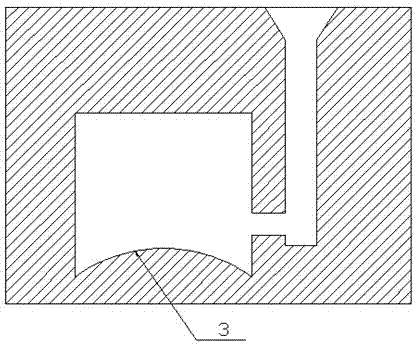

[0021] B. Make the guide plate model according to the requirements of the casting process (3);

[0022] C. Lay the mixture prepared in step A on the working surface of the guide plate model (3), and compact it properly, and its thickness is 3mm;

[0023] D. Select Cr15 high chromium steel as the base metal (1). After smelting and melting in an intermediate frequency furnace, it will be released at 1580°C. Pour Cr15 high chromium steel into the model (3) until it is full;

[0024] E. After the base metal liquid is cooled and solidified, take out th...

Embodiment 2

[0026] Such as figure 2 , 3 As shown, to prepare a composite material guide plate with tungsten carbide and silicon carbide particles as the hard phase and high carbon steel as the base material, the preparation steps are as follows:

[0027] A. Select tungsten carbide particles and silicon carbide particles (2) with a particle size range of -40~+60 mesh. The ratio of tungsten carbide particles to silicon carbide particles is 1:1. According to the weight of ceramic particles, add 3% polyethylene Alcohol and 5% cobalt powder, stir evenly;

[0028] B. Make the guide plate model according to the requirements of the casting process (3);

[0029] C. Lay the mixture prepared in step A on the working surface of the guide plate model (3), and compact it properly, and its thickness is 2mm;

[0030] D. Select high-carbon steel as the base metal (1), smelt and melt it in an intermediate frequency furnace, and release it at 1580°C. Pour high-carbon steel into the cavity of the model (...

Embodiment 3

[0033] Such as figure 2 , 3 As shown, to prepare tungsten carbide, silicon carbide, and silicon nitride particles as the hard phase, and 40Cr low-alloy steel as the substrate, the composite material guide plate is prepared as follows:

[0034] A. Select tungsten carbide particles, silicon carbide particles and silicon nitride particles (2) with a particle size range of -60~+80 mesh. The ratio of tungsten carbide particles: silicon carbide particles: silicon nitride particles is 2:1:1. According to the weight of ceramic particles, add 2% polyvinyl alcohol and 15% tungsten iron powder, and stir evenly;

[0035] B. Make the guide plate model according to the requirements of the casting process (3);

[0036] C. Lay the mixture prepared in step A on the working surface of the guide plate model (3), and compact it properly, and its thickness is 6mm;

[0037] D. Select 40Cr low-alloy steel as the base metal (1), smelt and melt it in an intermediate frequency furnace, and release ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com