Method for extracting thermolysis coal by coal tar

A technology of coal tar and low-temperature coal tar, which is applied in the field of coal tar extraction-pyrolysis coal, and coal extraction pyrolysis solvent, can solve the problems of liquid product yield to be improved, practical application, scale to be expanded, etc., to achieve utilization Extensive, low-cost solvent sources, and excellent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

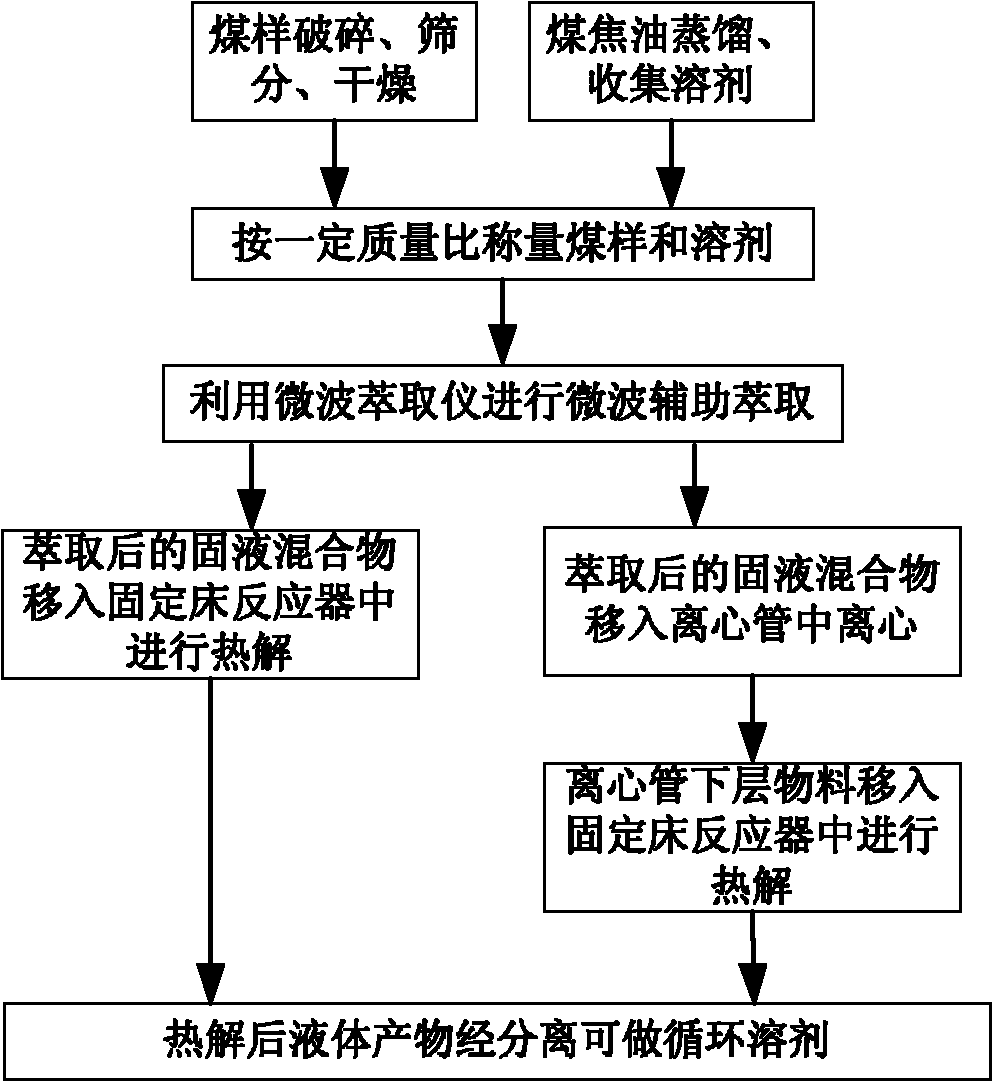

Method used

Image

Examples

Embodiment 1

[0049] 1) Raw coal pretreatment

[0050] The Shenfu long-flame coal was crushed and sieved by a pulverizer, and the particle size of the coal sample was less than 75 μm. Dry in a vacuum oven at 100±5°C for 6 hours, keep in a vacuum state and cool to room temperature, take it out and store it in a desiccator for later use.

[0051] 2) Solvent preparation

[0052] Distill the low-temperature coal tar in the distillation kettle, firstly remove the moisture in the coal tar, and collect the light distillate oil at 100-300°C as a solvent for later use;

[0053] 3) Extraction

[0054] Weigh 75g of coal sample and 227g of solvent, mix the two raw materials into the extraction tank, and use microwave to heat the mixture from room temperature to 200°C under normal pressure, and extract at constant temperature for about 30min; Cool and immediately drain the extraction mixture.

[0055] 4) Pyrolysis process

[0056] The extracted mixed product was pyrolyzed on an aluminum retort with...

Embodiment 2

[0058]The coal sample is the same as in Example 1, and the solvent is middle distillate oil at 180-360°C. Weigh 45g of coal sample and 180g of solvent into an extraction tank. Under normal pressure, use microwaves to heat the mixture from room temperature to 200°C, and extract at a constant temperature for about 30 minutes. After the extraction is completed, pour the extraction mixture into a centrifuge tube while it is hot. Carry out centrifugation to above-mentioned extraction mixture in centrifuge, centrifuge speed is 3800rps, and centrifugation time is 15min; 550°C, residence time 20min. The conversion rate of pulverized coal is 29.4%. After pyrolysis, the coke is powdery, non-caking, dark gray and dull.

Embodiment 3

[0060] The coal sample is the same as in Example 1, and the solvent is middle distillate oil. Weigh 45g of coal sample and 136g of solvent into a round-bottomed flask, heat the mixture electrically, and when the temperature reaches 200°C, transfer the material into an extraction tank, and keep microwave radiation at this temperature for 20 minutes; tank, and pour the material into an aluminum retort for pyrolysis, with a pyrolysis temperature of 510°C and a residence time of 20 minutes. The conversion rate of pulverized coal is 38.8%. After pyrolysis, the coke is powdery, non-caking, dark gray and dull.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com